(996 products available)

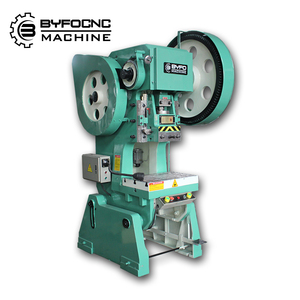

The mechanical eccentric press machine, also known as the mechanical press or eccentric press, remains one of the dominant stamping machines for metal shaping. The principle of this machine type is to use an eccentric wheel or cam to impart linear motion to the tooling. This means that the strike or cutting force of the metal material is imparted in a circular manner to stamp large pieces of metal. The operation tends to be smooth, so the power and energy consecrated are used without much loss. The tools used can be replaced or adjusted to cut various shapes and designs, and no complex control systems are needed to run the machine. The machine can be used with any kind of metal stamping die.

Mechanical presses have several different specifications, including types, stroke lengths, widths, force, and others. Their applications can be found in industries that require the stamping of metal parts and material shaping.

The force generated by a mechanical eccentric press is measured in tons. They have different tonnages, ranging anywhere from 5 tons to 1000 tons. Generally, an eccentric press machine has a higher force in comparison to its size, which means they can squeeze materials much better without taking up a lot of space on production lines.

In mechanical presses, the stroke length is the distance covered by the ram or sliding plate, which is the part that strikes or presses down on materials to change their shape. The length can vary between short strokes of 50 mm to 600 mm for standard models and even longer for specialized presses. Their slide movements are quick, efficient, and precise.

Mechanical presses can be divided into two main categories based on their shape. The first are bench-top presses that are affixed to tables and workstations. They are ideal for home workshops and light industries. The second are floor presses that are bigger in size since they are built into the floor or meant to stand on the floor. They are used for heavy-duty industrial applications and are suitable for manufacturing facilities.

Mechanical eccentric presses are used to produce simple shapes and complex-shaped parts such as inner panels, outer panels, bumper reinforcements, cross members, battery trays, air conditioning diffs, wheelhouses, support braces, seat truss, closures, door frames, floor pans, and various exposed and non-exposed body parts. They are also great at blanking, piercing, notching, basing, drawing, and flanging solid materials.

Due to their high tonnage capability and precision stamping, they are commonly used in the automobile industry to manufacture bumpers, auto body parts, automobile frames, battery steel parts, chassis, structural parts, drilling machine, appliance, piping, and containers industry. They are great for making anything from household appliances to auto parts.

Mechanical presses are valuable machines that can streamline production processes. They work excellently with eccentric gearboxes that can be used as feeders in supply chains. To find out more about how a gearbox works with a mechanical press, please contact our sales team.

The mechanical eccentric press machine is popular in the metalworking and manufacturing industries worldwide, mainly for its efficiency and cost-effectiveness. This durable and versatile machine performs various essential jobs with metal sheets, such as punching, stamping, forming, bending, and coiling, to name a few.

Mechanical presses work well with metals like aluminum alloy, low-carbon steel, stainless steel, and other ferrous materials. The feeding methods are simple. An automatic feeder can be used to feed workpieces one by one or continuously for a long time. A roller table, conveyed by a belt, is another popular feeder method. For thin sheets, a hydraulic table is a good option. Manual feeding is popular for small jobs with fewer sheets or workpieces to be processed.

Punching and stamping are the dominant applications. Here, mechanical eccentric presses cut out complex shapes on the metal sheets with ease and precision. The cut-out designs can be holes, notches, and other intricate patterns. Dials on car dashboards are just one example. They are also used to create holes in automotive parts.

In the automotive industry, mechanical punches shape various parts and components like body panels, frames, brackets, mounts, and reinforcements, to name just a few. For instance, it can cut and shape the body panels and the chassis accurately. The resulting assembly will be smooth. It's no wonder this machine is often called the workhorse of the automotive industry.

Besides automotive body panels and structural components, mechanical eccentric presses are used to create closures like hoods and trunks. They also make essential parts like electrical connectors, switches, and bus bars. Other examples include brackets, bearings, and transmission parts.

Steel strips are cut and shaped with an eccentric punching machine to make electrical steels, transformer steels, silicon steels, and cold-rolled steels, to name a few. The diverse steel types are then used for generators, motors, and transformers, among other electrical appliances and equipment.

The press can also perform other functions like bending metal workpieces to desired shapes and forming parts to make complex shapes. For instance, it can bend and form metal sheets to make sink basins. The possibilities are endless!

Understanding the various aspects of the mechanical eccentric press helps business buyers know what to look for when purchasing it.

Q1: Are mechanical eccentric presses still used today?

A1: Yes. The ancient presses are still in use today. While technology has introduced more models, the mechanical eccentric press remains popular in factories that make parts in bulk and dont need mazilee control over the material.

Q2: What are the alternatives to an eccentric press?

A2: Mechanical presses come in four main types -the eccentric, gear, link, and flywheel presses. The gear, link, and flywheel presses function like the eccentric press. However, they deliver different types of unmarried force. The clutch of a flywheel press transfers a lot of energy to go higher than the eccentric press. A flywheel Press can work with thicker materials. It has a higher power output.

Q3: What determines the size of a mechanical press machine?

A3: The size of a mechanical eccentric machine is determined by the size of the parts to be made and the thickness of the material. Larger machines with higher tonnage are required to make parts with larger dimensions. For parts with a higher material thickness, a larger machine with more tonnage is also needed.

Q4: What are the safety features of a mechanical press machine?

A4: The safety features cut the risk of injuries during operation. The safety features of a mechanical press include two-hand anti-trim devices and guards. It may also include light curtains and emergency stops. The two-hand anti-trim device requires the operator to press the buttons with both hands. This prevents the press from closing on the hands. Guards are physical barriers that cover moving parts. The light curtain uses an array of light beams to detect movement in the press. If a person breaks the light beams, the press will stop. The light curtains are used to protect the hands and any part of the body that may get injured. An emergency stop is a large red button that brings the machine to a stop. The operator uses it to stop the machine in emergencies.