(642 products available)

Cheap rubber extruders are commonly used in the rubber industry for molding and forming rubber products. The following are some types of rubber extruders.

General Rubber Extruder

The general rubber extruder consists of an electrical motor, an oil pump, a flow valve, an oil cylinder, a die, a guide plate, a nozzle, and an extruding head. The oil pump transmits high-pressure oil to the oil cylinder to push the rubber compound to flow into the die through the nozzle to form a die filling. Changing the pressure of the flow valve can change the rubber compound's extruding speed and the product's thickness. The general rubber extruder has the advantages of simple structure and easy operation.

Rubber Calendering Machine

The general rubber extruder can also be regarded as a feeding device for the rubber calendering machine. The rubber calendering machine is primarily used to spread and control the thickness of rubber materials. It can be used not only to press rubber into sheets and other shapes but also to laminate other materials, such as cloth, to form composite materials.

Continuous Extruder

The general rubber extruder can also be regarded as a feeding device for the rubber calendering machine. The rubber calendering machine is primarily used to spread and control the thickness of rubber materials. It can be used not only to press rubber into sheets and other shapes but also to laminate other materials, such as cloth, to form composite materials.

Thread Extruder

The wire drawing type rubber extruder is specially designed to extrude rubber products with wires. It combines rubber materials with wires to make products for higher strength. Its features include a precise extrusion barrel and die, a traction, and a cutting system.

Multi-Layer Rubber Film Extruder

The multi-layer rubber film extruder can produce rubber films with multiple layers. It is suitable for producing multi-layer rubber films with different materials and structures. The main features are its precise extrusion temperature control system and the high accuracy of the die and thickness adjustment devices.

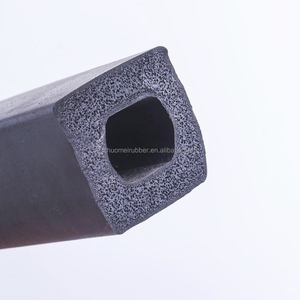

Rubber Sheet Drayer

The rubber sheet drafter is designed to extrude sheets of rubber with a wide range of applications. It is often used in the production of rubber sheets, rubber flooring, and sealing strips. The advantages of the rubber sheet drafter include its ability to process various types of rubber raw materials and its high production efficiency.

Tire Blank Extruder

The tire blank extruder is a special type of rubber extruder that can produce tire blanks or rubber strips. It has multiple feeding systems and die systems to meet the requirements of different tire types.

Power rating

The power rating of a rubber extruder can vary significantly depending on the business's needs and the model they choose to purchase. Generally, the power rating can be anywhere from 3 kW to 90 kW or even higher. A higher power rating indicates a stronger motor that can process rubber at a higher volume and speed.

Production capacity

This is the amount of rubber product the extruder machine can produce in an hour. The production capacity can range from 25 to 350 kg/h or more. Factors such as the type of rubber material, product complexity, extruder design, and operating conditions can influence the production capacity.

Temperature control

Temperature control is crucial in rubber extrusion, as it affects the material's viscosity and the final product's quality. Extruders come with multiple heating/cooling zones with in-built temperature control. Typically, there are 2-6 zones, and the temperature can range from 30°C to 120°C or more, depending on the material being processed.

Tread Width

The width of the rubber tread is another important specification. The width will depend on the specific requirements of the company's operations and can range from 50 mm to 300 mm or more.

Die change

The ability to change extrusion dies is an essential specification as it determines the flexibility and versatility of the extruder. Some extruders have quickly changed dies, allowing for smooth production.

Lubrication

Regular lubrication ensures that bearings, gears, chains, and belts are well-lubricated. Automating the maintenance with centralized lubricating systems can reduce the manual requirement.

Regular inspections & cleaning

Regular inspections of the extruder parts help maintain product quality.Appropriate cleaning methods and materials should be used to clean each part of the rubber extruder, and it's important to avoid any damage to the delicate components.

Preventive maintenance program

Develop a preventive maintenance program for scheduling and performing planned maintenance tasks on a timely basis.

Extruder operation

To maintain the durability of a rubber extruder, it's essential to use it correctly. Avoid overloading the machine beyond its capacity, maintain a steady feeding rate of the material, and ensure the temperature is appropriate for the type of rubber being processed.

Tire manufacturing:

The core application of a rubber extruder machine is in the tire manufacturing industry. Luxurious, high-performance, and tough tires are made using rubber extrusion machines. Automated machines produce tires efficiently and meet market demands.

Automotive industry:

Demand for efficient rubber production is increasing due to the expanding automotive industry. Rubber components are essential for smooth vehicle operations. The extruder helps create seals, gaskets, weather strips, and suspension parts quickly and in high volumes to meet the needs of the booming automotive sector.

Consumer goods production:

The rubber extruder also makes consumer goods. Rubber products made by the machine include footwear, sports goods, toys, gloves, and flooring. Extruders can produce large quantities quickly to meet consumer demand.

Construction industry:

The construction industry uses rubber products for structural support, sealing, waterproofing, and vibration damping. Rubber extrusion machines offer flexibility and precision for making construction-related rubber components, helping to enhance project quality and efficiency.

Medical and healthcare applications:

Rubber extruders can make soft, flexible rubber parts for medical devices. These include gaskets and seals for frictionless functioning of machines. Other components made are soft-touch grips, tubing, and sterile disposable products. The rubber parts are produced quickly to support the growing demand in the healthcare industry.

Agricultural machinery:

Agricultural machinery uses rubber components for protection, sealing, and vibration dampening. Examples are tractors and harvesters. The rubber extruder makes farm machinery parts more quickly and precisely, helping to improve the efficiency and durability of agricultural equipment.

Production Requirements:

When selecting a rubber extruder machine, it is crucial to consider the business's production demands. Factors such as output volume, the frequency of operation, and the desired product quality should all influence the choice of the extruder.

Horsepower:

For small businesses, a rubber extruder machine with 5 to 15 horsepower may be sufficient, while larger commercial enterprises may need more powerful extruders with higher horsepower to meet their production demands.

Material Compatibility:

It is essential to consider the types of materials that the rubber extruder can process as well as the production of end products required. Different rubber extruders are designed to work with specific types of materials, such as natural rubber, synthetic rubber, TPE, or other thermoplastics.

Ease of Operation and Maintenance:

It is crucial to consider the user-friendliness and maintainability of the rubber extruder. A well-designed machine that is simple to use and maintain can help decrease downtime and improve productivity. Look for features such as clear operating instructions, accessible maintenance points, and durable construction.

Total Cost of Ownership:

When choosing a rubber extruder, it is necessary to consider more than just the initial purchase price. It is equally important to consider the total cost of ownership, which includes energy consumption, operating efficiency, maintenance costs, and potential repair expenses over the life of the machine.

Technical Support and Customer Service:

It is essential to consider the vendor's technical assistance and customer service as well as their global presence. Businesses can benefit from prompt assistance, spare part availability, and convenient repair services, thereby reducing machine downtime and production disruptions.

Q1: How has technology impacted rubber extrusion machines?

A1: Technology has improved the rubber extruder machine's precision, efficiency, and automation. Cutting-edge control systems ensure precise temperature and pressure regulation. This results in high-quality output with minimal defects. Automation has led to more sophisticated rubber extruders with self-regulating feed systems and streamlined processes requiring less human interaction.

Q2: What does the future hold for rubber extrusion machines?

A2: The rubber extruder machine market is expected to grow steadily in line with the demand for rubber products driven by industrial growth and advances in automotive technology. Extrusion machines are expected to become more intelligent, incorporating artificial intelligence and machine learning for better process control and quality.

Q3: What are the main parts of a rubber extruder?

A3: The main parts of a rubber extruder include the feeding system, heating/cooling system, conveying system, die system, and cutting or tooling system. Different types of cheap rubber extruders may have different configurations.

Q4: What are the advantages of rubber extrusion?

A4: Rubber extrusion is a cost-effective manufacturing method. It is suitable for large-scale production and offers flexibility in design.