(633 products available)

Reinforced zinc oxide

This type of zinc oxide uses rubber or elastomer reinforcements, often found in higher strength or performance-demanding formulations. Usually, they are used in tires, industrial belts, and hoses, where better durability and resistance to wear is required.

Organic zinc oxide

This is an alternative to the typical organic zinc oxide. It is a type of reinforced zinc oxide that can sometimes contain small amounts of organic compounds to enhance the bonding between the filler and rubber. The organic modifiers are normally used to improve the compatibility of zinc oxide with certain rubber grades to ensure that the active materials remain in a state favorable to improving the rubber's characteristics.

High loading zinc oxide

This type of zinc oxide is defined by the amount included in the rubber compound and is characterized by the use of high concentrations of zinc oxide. They are usually used in specialized applications, like medical or pharmaceutical-grade rubber products, where antibacterial properties and the prevention of degradation by sulfur or other accelerator are necessary.

Non-marking zinc oxide

A non-marking zinc oxide is often used in tires, rollers, and other rubber products used in places where cleanliness and non-traces are desirable, for instance, in food processing facilities or on floors in cleanroom environments. It is constructed to ensure that there is no provision of black stains or spots on any surface, even as it gives the necessary functional benefits for rubber compounds to resist degradation and wear.

Rubber manufacturing

In rubber manufacturing, zinc oxide is mostly used as a reinforcing agent and curing accelerator. It promotes vulcanization through reactions with sulfur compounds in the presence of heat, forming sulfur cross-links in elastic polymers.

Tire production

One of the most important applications of zinc oxide is within the production of tires, where it aids in the strengthening of rubber, hence making it better able to endure wear and degradation caused by heat and environmental factors. Also, it has an antiseptic nature that helps to prevent damage to the tires caused by close microorganisms, such as bacteria and fungi.

Filler systems for rubber compounds

Zinc oxide is incorporated into such filler systems, combined with silica or carbon black, to enhance the mechanical properties of elastomers, such as tensile strength, elasticity, and resistance to tear. Such improvement allows rubber products to last longer under extreme conditions.

Coatings and paints

In coatings and paints, zinc oxide is also known as a pigment and opportunistic metal for corrosion protection. It gives whiteness and opacity, acting as a shield against rust and also being protective against ultraviolet light, which is harmful to organic substrate degrading over time.

Antibacterial and antifungal properties

The medical and pharmaceutical fields use zinc oxide as an active ingredient in dermatological biscuits and creams for its antibacterial and antifungal properties. Due to its healing and protective functions, it is usually used in diaper rash treatments and sunburn and other skin irritations.

Electronics

In electronics, due to its semiconducting properties, zinc oxide is used in producing varistors that protect electrical circuits from voltage transients and spikes. In addition, it's been the focus of intense research into its potential use in next-generation electronic devices like UV emitters, laser diodes, and sensors.

Sunscreens and cosmetics

In cosmetics, especially sunscreens, zinc oxide is used widely for blocking UV radiation, thus avoiding skin damage. It is generally considered safe, especially for sensitive skin and children, being a mainstay of physical or mineral sunscreen that provides broad-spectrum UV protection.

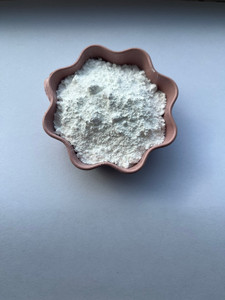

Zinc oxide is a white, powdery, inorganic substance made from zinc and oxygen, which is mainly produced by heating zinc metal in an oxygen-rich environment or processing zinc ore through hydrometallurgical techniques. Some of its key features include:

Typical particulate properties

Tamper-proof and abrasive resistant. This makes it highly effective in applications where it needs to remain operational under pressure or within aggressive/corrosive environments. Also, it's a fine particle that passes through a sieve with mesh number 25 and is able to almost completely pass through a sieve with mesh number 100.

Typical functional properties

Acts as an opacifier, UV filter, photocatalyst, antibacterial agent, and electronic property enhancer of semiconductors. The opacifier role makes it useful for coating and paint, while the UV filter characteristic, combined with its nontoxic nature, makes it very applicable in the cosmetic formulations of sunscreens.

Particle size

Particle size distribution is a very important aspect of zinc oxide, as it can have effects on its reactivity and physical properties. Able to give a better texture and enhance dispersion in a thrill or sophisticated application, zinc oxide has finer fractions. On the other hand, larger particles improve the blocking effect in paints or sunscreens.

Zinc oxide is used in different ways depending on its application or intended use. In rubber compounds, it's combined with other fillers and reforming agents through rubber mixing processes to produce tires and industrial belts. High-performance systems and reinforced grades are normally used for demanding applications such as engine components, aerospace, and military gear.

For pharmaceuticals and cosmetics, zinc oxide is produced in a fine, safe, and high-purity grade form that's incorporated into topical skin treatments, sunscreen formulations, and ointments. Construction uses it in paints and coatings with resins as part of the formulation to block corrosion and UV rays and provide structural integrity.

In electronics, zinc oxide powder is synthesized based on defined particle size and purity requirements that are formed into semiconductors, UV diodes, and piezoelectric devices using advanced manufacturing techniques like sol-gel methods and screen printing. For packaging, it's categorized into different grades and packaged according to particle size distribution, purity, and usage to ensure that only the necessary functional properties were delivered to the buyer.

Zinc oxide, being stable, does not need special maintenance, but its effective properties need continual monitoring and evaluation, especially for industrial applications. In rubber products, continuous observation of wear and tear, along with performance evaluation tests that check the mechanical properties of the rubber over time, helps determine the need for replacement or reinforcement. In medical or cosmetic applications, the stability and purity of zinc oxide must be routinely controlled, especially for products that have a direct effect on human health, like creams and ointments. They should observe regulations set by health authorities for quality control in order to improve product safety and effectiveness. For electronic devices, performance checking and routine calibration help detect potential issues related to the devices containing zinc oxide semiconductors. This also means that the lifetime of such devices can be optimized, and users can have a better experience.

Occupational exposure limits (OELs)

The OELs indicate the concentration levels that workers can be exposed to safely over a given time period without incurring adverse health effects. These limits are set by regulatory agencies and might be specific for different countries or regions. For zinc oxide, there is no universal consensus on ACGIH and OSHA, but they have some values that are regionally specific. It is important to note that OELs can vary depending on whether the zinc oxide is being processed in a fume, dust, or particle format.

Respiratory protection

Respiratory protection is necessary where airborne concentrations of zinc oxide exits, possibly exceeding OELs or Where OELs DO NOT EXIST, workers should be encouraged to wear respirators with proper filters for particulates, such as P2 or P3 respirators, effective against dust containing zinc oxide. Other factors that affect the type of respirator to be used are the level of exposure, the comfort factor, and the work conditions.

Proper ventilation and work hygiene

Good ventilation is among the most effective ways to reduce airborne contaminants, including zinc oxide particles. Open areas should be well ventilated; local exhaust ventilation should be utilized in confined or enclosed areas. This is another hygiene practices to prevent or reduce the likelihood of ingestion or skin exposure - for example, prohibiting eating or drinking in work zones and ensuring that workers take showers and change into clean clothes after work.

Environmental considerations

By controlling the release of zinc oxide into the atmosphere, water, or land, the possible effect on ecological systems should be minimalizable. Such controlling methods can be dust suppression systems, proper waste disposal practices, and treatment of wastewaters. Regulatory compliance involving emissions and discharge limits for zinc concentration is also important. Periodic monitoring and assessment of the level of zinc oxide in environmental media are usually conducted to check compliance with possible adverse effects on flora and fauna to minimize ecological risks.

First aid measures for exposure

First aid measures usually undertaken by exposed individuals include encouraging them to move from the affected area, breathing fresh air, and drinking plenty of water when exposed to zinc oxide fumes. If symptoms persist, they are advised to seek medical assistance. Medical professionals, when treating patients with symptoms similar to respiratory distress or skin irritation, need to be informed that there has been an exposure to zinc oxide.

It's a mineral that provides broad-spectrum protection from UVA and UVB rays of the sun. It does this by reflecting and scattering the rays from the skin rather than absorbing them like chemical filters. Usually, it's a go-to for sensitive skin and babies because of its gentleness and proven safety record. It also provides a physical barrier that helps stay irritants away from the skin, which is why it's commonly used to treat diaper rash.

An important feature of Zinc Oxide is that it works as a cure and accelerator promoter. This means that it helps make the rubber used in the tires stronger and stretch better. A zinc oxide particle provides tiny bits of zinc that help the rubber molecules link together during the tire-making process. This leads to better handling, a smoother ride, and much longer-lasting tires, which is what everyone needs – less wear and tear.

The good news is that there is a lot of testing and research on Zinc Oxide, so they are definitely saying it's safe. It is even approved for use in sunscreens by the FDA and other global agencies like Health Canada's, so it is clear that it is safe kind of after sunbathing. Also, it has been checked and found safe for babies and folks with easily irritated skin, so all the people it tends to worry the most are just fine with it.

Zinc oxide usually appears as fine, white powder. It has no taste and is nontoxic, although its powdery texture might make it feel a little strange if it gets in the mouth. Some folks say it has a chalky kind of feel to it. In addition, it does an excellent job covering up skin and tends to stay there until washed off.