(1653 products available)

Yellow-coloured grating comes in diverse types. They include:

One of the most used materials for yellow steel grating is powder coating, which gives a durable and corrosion-resistant finish. Usually, yellow steel grating is ideal for heavy-duty applications, both in construction and industrial demands. In addition, the bright yellow colour improves visibility, which makes it essential for safety-critical environments.

Ideally, yellow stainless steel grating incorporates yellow powder or vinyl coating over stainless steel. This new replication retains the rust-resistant properties of stainless steel. Further, it adds a layer of chemical-resistant protection. Henceforth, this combination is ideal for applications in harsh environments while maintaining an attractive appearance.

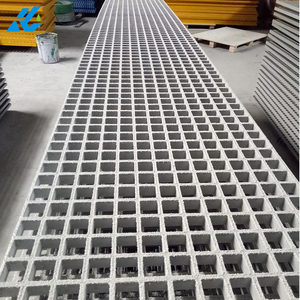

Yellow FRP grating is manufactured to be lightweight and exceptionally strong. This highly promotes the use of yellow frp grating in corrosive environments and over water, where metal grating would quickly rust. Also, yellow FRP grating comes with high-visibility surfaces. This makes it critical in settings that require good safety markings.

Aluminium grating is lightweight and non-corrosive. Often, it is ideal for outdoor applications. Ideally, yellow aluminium grating creates a unique combination of functionality and aesthetics. While it may not be as strong as steel, the heightened visibility and resistance to oxidation make it fitting option for diverse application.

Yellow-coloured grating has myriad applications. They include:

Large warehouses, factories, and commercial buildings normally employ yellow safety grating in high-traffic areas. Yellow grating comes in handy in enhancing visibility. This helps workers avoid hazards and thus reduce the risk of trips and falls. In addition, their bright colour makes them integral parts of safety pathways, access points, and maintenance areas.

Developments like scaffolding and walkways, often adopt yellows grating. Usually, yellow caution tape grating alerts workers to potential dangers, as slippery surfaces or areas with heavy machinery. Besides, it is critical on construction sites where safety is a major priority. The bright colour contributes to improved awareness of the surrounding hazards.

Marine and freshwater facilities, which include boats and docks, majorly utilise yellow grating. It provides excellent slip-resistance and does not rust. Also, yellow FRP grating, in particular, is commonly used in these settings since it retains its colour and integrity, despite the harsh saltwater environment. Additionally, the yellow colour designated safety areas and helps workers navigate slippery surfaces.

Transportation hubs like airports and bus terminals employ yellow-coloured grating in walkways and access ramps. This enhances the visibility and safety of pedestrian paths. More importantly, it guides people through busy areas, preventing accidents and ensuring a smooth flow of traffic, as it can be seen even in dim-lit applications.

Yellow safety grade grating is widely used in emergency exits and evacuation routes. Normally, its presence guarantees that people can swiftly find their way to safety during emergencies. It comes with visibility resistant to colour blindness and low illumination conditions, thus becoming indispensable in situations that require quick action.

Yellow-coloured grating comes with numerous benefits. They include:

Yellow safety grating enhances safety by demarcating hazardous areas and key pathways, as yellow visual spectacle is a notable feature of the coloured grating. This minimisation of accident risk is a great achievement in high-traffic or industrial settings. Consequently, this application will always draw attention to critical zones and thusly improves pathway navigation.

Yellow fibreglass grating, in particular, is highly resistant to corrosion, making it ideal for outdoor and chemical-exposed environments. The corrosion-resistant properties ensure longevity and minimal maintenance as the grating can endure adverse weather and chemical exposure without degrading. Also, this durability keeps aesthetic appeal and function over time.

Yellow grating is extremely versatile, making it ideal for diverse applications. These applications normally include industrial plants, walkways, and platforms. Often, it is adapted to various loading requirements and environmental conditions, making an ideal solution for both commercial and residential projects alike. Also, this versatility extends to manufacturing materials like steel, aluminium, and fibreglass.

The grating's yellow colour ideally enhances the non-slip surface properties, which togetherly minimise the chances of slipping and falling in moist or icy conditions. This characteristic makes yellow grating especially valuable in outdoor applications and areas prone to water exposure. In addition, it provides a secure footing for workers and pedestrians, thereby enhancing safety.

Yellow-coloured grating is usually designed with easy installations in mind. This saves time and costs when deployed on project sites. Besides, many grating systems come with pre-fabricated sections and lightweight materials. These significantly reduce the need for extensive modifications or structural reinforcements. Thus, the accessibility indicators that can easily fit into existing structures without hassle.

When purchasing yellow-coloured grating for sale, business owners ought to consider a plethora of factors. These factors not only should affect business owners' decisions but also improve buyers' satisfaction. Here are some of these factors:

When choosing yellow grating, it is important to consider the material types. These are steel, aluminium, and frp. Each material possesses its own merits. For instance, steel offers unmatched strength and heavy load support. On the other hand, aluminium is lightweight and rustproof. This makes it suitable for applications where weight is a serious concern. Also, FRP is designed to resist chemicals and corrosion. This makes it ideal for harsher enviroments.

Yellow grating comes in various types. Each type is based on the production process employed in creating them. For instance, some owners may prefer meshed yellow grating, which is also known as meshed yellow grating. Others may choose the concertina variant. Also, some may settle for framed grating, while others opt for non-framed grating. The choice between meshed and non-meshed grating will highly depend on the intended use. For instance, non-meshed grating will offer a solid surface, which is ideal for foot traffic. On the other hand, meshed grating can provide a solid surface while enhancing air and light circulation.

Yellow grating is ideally suitable for outdoor applications. Thus, business owners should look for options with suitable surface treatments for outdoor applications. Normally, exposure to outdoor elements like rain and harmful UV rays can lead to the gradual depletion of the grating. Therefore, look for options with additional protective coatings like vinyl or powder.

Different yellow grating options are suited for varying loads and spans. When used as industrial flooring, the grating must be able to withstand the expected load (live and dead loads) in a particular area. Also, business owners should look for grating options that have been engineered to provide adequate support for spans. Normally, longer spans will require additional support since they are likely to flex more than shorter spans.

Usually, yellow grating finds multiple applications. One of these applications is walkways, where the grating usually provides a stable walking surface. Also, it can be mounted on platforms to create open areas for workers. Sometimes, this grating is used as covers for trenches or drains, where it supports the cover's weight while preventing accidental falls.

Q1. The most effective way to increase the durability of yellow safety grating is by utilising yellow powder coating, which protects the grating from physical damage and rusting. In addition, regular cleaning of the grating helps remove the dirt and debris that may be accumulating and leading to wear.

It depends on the type of the grating. Yellow fibreglass grating, in particular, is more suitable for outdoor applications since it does not rust like metal-based gratings. It is also non-conductive, which enhances its suitability in industrial applications. Unfortunately, painted metal-based yellow gratings are likely to rust over time. This is if the paint wears off due to outdoor exposure.

A kneepad designed for walking grating should incorporate a rubberized shell to prevent slipping. In addition, it should have a good combination of tight yet comfortable fitting straps and anti-slip rubber surfacing to eliminate the possibility of slipping. Also, it should have good-quality padding to ensure comfort and safety, as it will eliminate the possibility of falling over, which is generally low.

Since painted metal-based yellow grating uses paint as a protective layer, it is recommended to use a sealant designed for protecting the paint. Water-Repelling Sealants are well renowned for this kind of application. They not only keep the paint from becoming saturated over time but also shield the painted surface from dust, debris, and other contaminants.

Yellow hazard tape grating is mainly developed for hazardous applications. Commonly, this level of application only goes to industrial areas. The bright yellow colour acts as a warning of potential danger zones. This makes it easier for personnel to identify areas that require caution. Moreover, the mesh design provides a minimal surface that permits airflow and light while offering a load-bearing surface.