(15193 products available)

Wooden fiberboard is a type of engineered wood product crafted from wood fibers, adhesives, and additives. These components are combined under heat and pressure to form a dense, flat board. Wooden fiberboards are versatile and come in different types, enabling them to be used for various applications. Below are the types of wooden fiberboard:

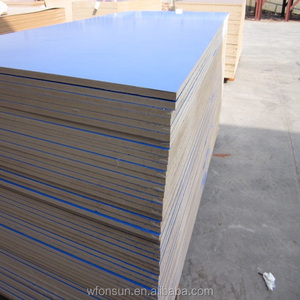

Medium Density Fiberboard (MDF)

MDF is an engineered wood product made from wood fibers, wax, and resin. These components are combined under heat and pressure to form a dense board. MDF boards are versatile and can be easily cut, shaped, and finished. They are used in furniture making, cabinetry, and interior molding. MDF is preferred in the construction industry because it is cost-effective and has a smooth surface that is ideal for painting.

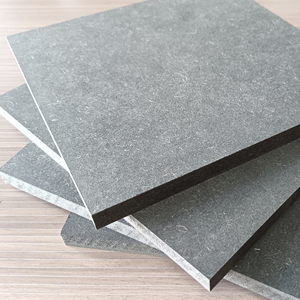

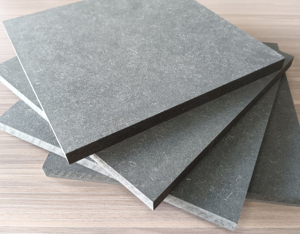

High-Density Fiberboard (HDF)

HDF is a type of fiberboard with a higher density than MDF. It is made from wood fibers, adhesives, and additives compacted under high pressure. HDF is durable and more resistant to wear, moisture, and temperature changes than MDF. It is used in applications requiring enhanced strength and stability, such as laminate flooring and high-traffic areas. HDF comes in various grades, such as HDF floor and HDF wall.

Hardboard

Hardboard is a type of wooden fiberboard made from wet process and compressing it into a single board. It is usually made without adding chemicals, making it a more natural product. Hardboard has a smooth surface on one or both sides and is denser and thicker than MDF. It is more affordable than MDF, but its uses are limited. Hardboard is mainly used in applications like drawer bottoms, cabinet backs, and wall panels.

Softboard

Softboard is a type of wooden fiberboard made from large wood chips or strands bonded with resin. It is lighter, less dense, and has a more textured surface than other fiberboards. Softboard is usually left untreated or with a simple finish to highlight its natural appearance. It is used for insulation, acoustic panels, and ceiling tiles.

Wood fiber board is used in many applications. Their versatility enables their use in various applications regardless of industry. Here are the features and functions of wood fiber board.

Insulation

Insulation wooden fiberboards are used in building energy-efficient homes and other structures. Their insulation properties reduce the amount of energy needed to heat or cool a building. Reducing energy demand is good for the environment. Insulation boards are easy to work with, which makes them a good choice for builders.

Structural

Structural wooden fiberboards, such as OSB and strand boards, can be used in the construction of walls, roofs and floors. They are strong and stable. This means they can carry loads without bending or breaking. Structural boards are made from small pieces of wood, which makes good use of the wood.

Decorative

Decorative wooden fiberboards are used in the interior and exterior finishing of buildings. They add beauty and warmth to a space. These boards come in many finishes, colors and textures. This allows designers and homeowners to choose what they want. These boards are also made from sustainable materials. They are a good choice for people who care about the environment.

Composites

Composites are special wooden fiberboards made from wood dust mixed with glue. They are made into products like cabinets, furniture, countertops and particle board. Composites are popular because they are cheaper than solid wood. They provide a good surface for painting and finishing.

Soundproofing

Acoustic boards are designed specifically to reduce noise. They are used in offices, theaters and concert halls. Acoustic boards absorb sound waves, which reduces echoes and makes spaces quieter. They are also used to build walls and ceilings that block noise from traveling between rooms.

Residential Applications

Wooden fiberboard is widely used in residential homes. It is used in making furniture like cabinets, drawers, tables, and chairs. Wooden fiberboard is also used as a cost-friendly option for lining the interior of cabinets and drawers. It is also used as a substrate in upholstered furniture. Wooden fiberboard is also used in the construction of residential houses. It is used as an underlayment for floors and roofs. It is also used for sheathing walls and creating structural insulation. Wooden fiberboard is also used for decorative purposes. It is used as a backing for picture frames and mirrors. It is also used as a bulletin board in homes.

Commercial Applications

Wooden fiberboard is used in the commercial sector due to its versatility. It is used in the construction of office spaces. It is used as drywall sheathing and interior partitions. This allows the creation of different room layouts. Wooden fiberboard is also used as acoustic panels in offices. This helps to reduce noise levels and create a conducive working environment. Wooden fiberboard is also used in the hospitality industry. It is used in the construction of hotel and restaurant interiors. Wooden fiberboard is also used in creating furniture for dining areas and reception spaces.

Industrial Applications

Wooden fiberboard is used in many industrial applications. It is used as a substrate for industrial packaging. For example, it is used in making boxes, crates, and containers for shipping and storage. It is also used as a core material in the construction of pallets and skids. Some types of wooden fiberboard, like high-density fiberboard, are used in the manufacturing of engineered wood products. It is used as a binder material in the manufacturing of oriented strand board (OSB) and particleboard. Additionally, it is used as a core layer in the production of medium-density fiberboard (MDF) and high-density fiberboard.

Specialized Applications

Wooden fiberboard is used in specialized applications. For example, it is used in the production of acoustic wooden fiberboards. These boards have specific surface patterns that help to absorb sound waves. This minimizes echo and reverberation in concert halls and auditoriums. Wooden fiberboard is also used in the manufacture of fire-rated wooden fiberboards. These boards are engineered with fire-retardant additives. This helps to meet the building code requirements for fire safety. Additionally, wooden fiberboard can be treated to resist moisture and mold. This makes it suitable for use in bathrooms and kitchens.

When choosing a wooden fiberboard, there are a number of factors that should be considered. Here are some of them:

Moisture Resistance

When purchasing wood fiber boards for projects, it is important to consider the fiberboard's intended use. Will it be used in areas with high humidity or moisture like kitchens and bathrooms? If so, then a moisture-resistant fiberboard should be considered.

Board Thickness and Density

The thickness of the board can affect the structural integrity of the fiberboard, while the density can affect the quality of the finish. As such, it is important to consider the load-bearing requirements and the desired end finish when choosing the board thickness and density.

Compatibility with Adhesives

Buyers should consider the type of adhesives used during the construction process as some adhesives work better with specific types of boards. For example, HMR boards are compatible with urea-formaldehyde adhesives, while MR boards are compatible with PF adhesives.

Acoustic Properties

For projects where acoustic control is required, such as in home theaters or studios, it is important to consider the fiberboard's sound absorption properties. In such cases, the use of acoustic wooden fiberboard is recommended.

Ease of Handling and Machining

Extra consideration should be given to the wooden fiberboard ease of handling and machining, especially when working on large-scale projects. This is because lightweight boards that are easy to cut and shape can save time and reduce labor costs.

Edge Sealing

In addition to choosing the right type of wooden fiberboard, buyers should also consider edge sealing to improve its durability and performance. As such, the edges of the boards should be sealed with appropriate materials to protect them from moisture and pests.

Environmental Impact

Buyers should consider the environmental impact of the wooden fiberboard to promote sustainable forestry practices. This can be done by choosing boards made from recycled wood fibers or those manufactured with environmentally friendly adhesives and resins.

Q1: Is wooden fiberboard waterproof?

A1: Wooden fiberboard is not waterproof. It is made from wood fibers, which are bonded together using adhesives and then compressed. Therefore, water can damage the wooden fiberboard by causing it to swell or warp. Nevertheless, some types, like MDF, have water-resistant properties. They can be used in areas with high humidity, such as bathrooms and kitchens.

Q2: Can I paint or stain wooden fiberboard?

A2: Yes, it is possible to paint or stain wooden fiberboard. However, the type of fiberboard used will determine the finish. For instance, smooth surfaces are achieved by painting MDF, while a stained look is obtained from hardboard.

Q3: Does wooden fiberboard contain formaldehyde?

A3: Most wooden fiberboard contains formaldehyde. This chemical is used in the adhesives that bond the wood fibers together. It is important to note that formaldehyde can be harmful. Therefore, it is recommended to seek fiberboards with low or no formaldehyde emissions.