(2631 products available)

A wood planer moulder is used to shape and trim pieces of wood from all sides to achieve an even finish. There are many ways to categorize wood four side planers.

According to size and capacity:

The wood moulder planer machine can achieve 100-200 mm for the minimum and maximum width, respectively. The maximum drawing length of the machine can be between 300-6000 mm. The machine is massive, weighing around 3,000 to 5,000 kg.

According to its mechanism:

Horizontal spindle: The four-sided horizontal spindle wood planer moulder machine has a cutter head under the wood to be moulded. The horizontal spindle machine is suitable for wood pieces with complex profiles.

Vertical spindle: The four-sided vertical spindle machine has four cutter heads placed in a vertical manner. The blades will trim the sides of the wood vertically. This machine is ideal for making flat surfaces and chamfered edges.

According to feeding methods:

Gear feeding: In a geared feed wood planing machine, the driving mechanisms are cutter heads with gears. As a result, this machine has a powerful feeding force and a higher processing speed. The geared feeding machine can process harder wood materials.

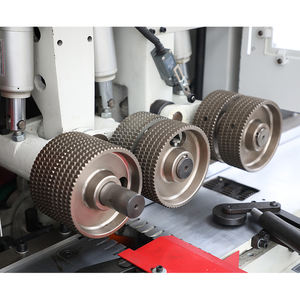

Roller feeding: In a roller feeding machine, the workpiece is drawn by rollers. This machine works quieter and has a wider range of applicable materials. It is more suitable for softer wood pieces.

Four-sided planers are commonly used in the wood processing industry. The tool is suitable for trimming all sides of wooden boards, including the more difficult-to-reach areas of wood. This machine is a must-have in any workshop tackling complex wood projects that call for high precision.

Here are a few industry scenarios where the wood four-sided planer moulder finds extensive use:

The above scenarios show how versatile and crucial four-sided wood planers are in the woodwork industry. With the machine, there is greater accuracy, efficiency, and uniformity when trimming and moulding wood.

For business buyers, it's essential to identify the wood four side planer moulders that will sell well. The first step is to investigate the target clientele's preferences. They should begin by selecting suppliers who offer varied planer moulders for sale. Then, they'll need to analyse the types of wood four sides planers their clients are purchasing. For instance, are they more interested in commercial-grade moulders or small workshop moulders?

Next, buyers should conduct in-depth research regarding the popular moulder features. Is it more important to their client base the cutting power of the planer moulder, its maximum planer width, the number of spindle and cutter heads, or its operating method (manual, semi-automatic, or automatic)? More importantly, buyers should seek answers to such questions by surveying existing customers.

Based on the answers from the surveys, buyers can finally choose the type of planer moulder that is in demand. If they are interested in purchasing in large amounts, they can negotiate for a wholesale price with the supplier. They can set a competitive price and earn a reasonable profit margin.

Additionally, if interested in purchasing different types of wood moulders, planers, and cutters, buyers can choose to display the items at their storefront to allow customers to choose their preferred models. They should further choose popular brands to ensure customer satisfaction.

Since most wood four side planers for sale are quite a big investment, buyers should consider investing in a wood planers with some advanced features. For instance, dust extraction features are great at keeping the workspace clean.

Q: Which wood moulder is best?

A: The best wood moulder depends on use. The wood used will dictate the type of moulder required, as different materials require different blades and planers. The amount of space needed will also affect which machine is best, as some machines can be broken into parts to save space, and others cannot. Larger production lines usually require more extensive planers to cope with the high demand, while smaller one-sided planers are more affordable for small businesses who do not need to machine as much wood per day.

Q: What is the difference between a wood moulder and a wood planer?

A: A wood moulder is used to shape wood into specific forms whereas a wood planer is used to flatten and level wood.

Q: What are the different types of wood moulders?

A: There are four main types of wood moulder, which include, the spindlemoulding machine, the automatic straight-throughfeed moulder, the thicknesser/moulder combination machine and the high-speed undercut moulders and profiler.

Q: Is a wood moulder worth it?

A: A wood moulder can be an excellent investment for businesses that regularly need to reshape wood into specific forms. The machine saves a lot of time when compared to doing the same job by hand and increases production lines, making the machine worthwhile for many businesses. Small businesses that do not reshape a lot of wood may find the price of the machine hard to justify.