(15133 products available)

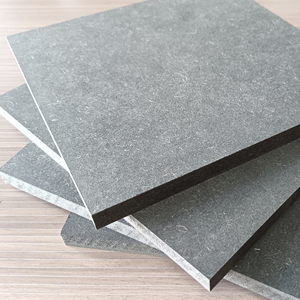

A wood fiberboard is an engineered wood product made from wood fibers, adhesives, and other additives. It is created through various processes that bond these components together to form a board. It comes in different types, which include the following:

Wood fiberboard is an engineered wood product made from wood fibers, adhesives, and additives. It comes in different types and is used for various applications in the construction industry. Here are some of its key features and functions.

Features

Wood fiberboard has different features that make it ideal for different applications. Some of the features include:

Eco-friendly: Most wood fiber boards are made from wood fibers, adhesives, and additives. They are manufactured using waste materials that would otherwise be discarded. Additionally, these boards are recyclable, which reduces the need for new raw materials and minimizes environmental impact. As a result, they appeal to businesses that prioritize environmental sustainability.

Uniform surface: Wood fiberboard has a smooth, uniform surface that is ideal for painting, veneering, or laminating. This makes it suitable for applications where aesthetics are important. In addition, the uniform surface reduces material wastage during the finishing process.

Insulation: Fiberboards have low thermal conductivity due to their dense and fibrous structure. This makes them suitable for use in energy-efficient buildings. These boards help maintain comfortable indoor temperatures and reduce energy costs. Additionally, some types of fiberboards are manufactured with special insulating materials, which enhance their insulation properties.

Lightweight: Wood fiber boards are generally lightweight, making them easy to handle and transport. This reduces shipping costs and improves efficiency on the job site.

Compatibility with fasteners: Fiberboards allow for easy and secure connections with screws, nails, and other fasteners. This makes them easy to work with and suitable for various construction applications.

Functions

Fiberboards are used for different applications in the construction industry. Some of their functions include:

Insulation board: As mentioned, these boards have good thermal insulation properties. Insulation boards are used in roofs, walls, and floors to improve energy efficiency and reduce heat loss or gain.

Sheathing board: These boards provide structural support and protection to buildings. They are used as sheathing in walls and roofs to create a weather-resistant barrier and improve fire resistance.

Substrate: Wood fiber boards are used as substrates in different applications. For example, they act as a base layer in laminated surfaces or as a substrate for flooring materials like laminate or vinyl flooring.

Soundproofing: Some wood fiber boards have enhanced acoustic properties. They reduce noise transmission and improve sound insulation in walls, floors, and ceilings.

Moisture control: Certain types of wood fiber boards are manufactured with additives that provide moisture resistance. They control moisture and prevent condensation, which protects the building components from mold and rot.

Vapor barrier: Wood fiber boards are used as a vapor barrier in construction. They prevent the passage of water vapor from the interior spaces to the exterior, which protects the building from moisture damage.

Wood fiberboard is a versatile engineered wood product with various applications across different industries. Here are some of its common usage scenarios:

Construction and Building

Sheathing: Provides a strong and stable surface for walls, roofs, and floors. It is used as structural sheathing in building construction, offering load-bearing support and moisture resistance.

Subfloors: It is used as subflooring material in residential and commercial buildings, creating a solid base for finished flooring.

Interior Walls: Used in non-load-bearing walls and partitions, offering a cost-effective solution with good acoustic properties.

Furniture Manufacturing

Cabinetry and Drawers: Commonly used in the construction of cabinets, drawers, and other storage units, providing a balance of strength and affordability.

Desks and Tables: It is used in the production of desks, tables, and other surfaces, especially in budget-friendly office and home furniture.

Upholstered Furniture: Acts as a durable and lightweight frame material in upholstered furniture, such as sofas and chairs.

Interior Design

Wall Panels: Allows the creation of textured wall panels, such as cork or felt wall coverings, that enhance aesthetics and acoustic properties.

Decorative Elements: Used to manufacture decorative moldings, trim, and architectural features, offering design flexibility.

Acoustic Panels: Engineered to produce acoustic panels and tiles that improve sound quality and reduce noise in spaces like theaters and recording studios.

Automotive Industry

Interior Panels: Used in manufacturing interior panels, such as door panels, dashboard components, and headliners, due to their lightweight and insulating properties.

Sound Insulation: Acts as sound insulation material to reduce noise and improve the overall comfort of vehicles.

Consumer Electronics

Speaker Enclosures: Designed to create speaker enclosures and cabinets that enhance sound quality and reduce resonance.

Electronic Packaging: Provides protective packaging for electronics during transportation and storage.

Craft and DIY Projects

Hobby Projects: Popular among hobbyists and DIY enthusiasts for crafting small projects like picture frames, model buildings, and decorative items.

Crafting: It is used in crafting activities, such as making jewelry boxes, coasters, and personalized plaques.

Specialized Applications

Sound Studios: Used in professional recording studios and music venues for soundproofing and acoustic treatment.

Eco-Friendly Construction: Some types of fiberboards are made from recycled materials or sustainable sources, making them suitable for green building projects.

When choosing wood fiberboard, there are several factors to consider to make sure the product meets the intended design or construction needs. Here are some of the factors a buyer should consider:

Consider the Application

The first thing a buyer should consider is the application of the board. Different wood fiber boards are suitable for different applications. For instance, acoustic boards are suitable for sound insulation, while structural boards are suitable for load-bearing applications. Therefore, a buyer should definitely consider the application to ensure the board meets the specific requirements.

Consider the Type

As mentioned, there are different types of wood fiberboard. Each type has its advantages and disadvantages. Therefore, it is important for a buyer to choose the appropriate type that will suit their needs. For instance, if one needs a board for high moisture areas, they should choose mdf boards.

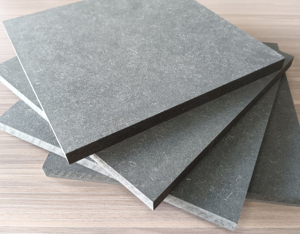

Consider the Thickness and Density

It is also important to consider the thickness and density of the fiberboard. The thickness and density affect the strength and stability of the board. Therefore, a buyer should choose a thickness and density that is compatible with the load or pressure it is being manufactured to hold.

Consider the Environmental Impact

Buyers who are environmentally conscious should definitely consider the environmental impact of the wood fiberboard. Most manufacturers indicate how environmentally friendly their products are. Therefore, choose a board that has been manufactured using sustainable practices.

Consider the Cost

Wood fiberboard comes with different prices depending on the manufacturer and the specifications. It is important to consider the cost to ensure it is within budget. However, while considering the cost, it is also important to consider the quality. Never go for a board just because it has a lower price; ensure it is of the required standard.

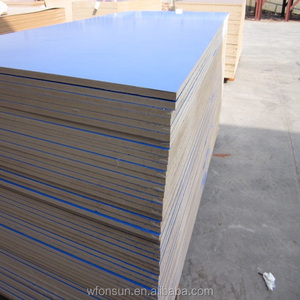

Q1: What are the sizes of wood fiberboard?

A1: The size of the wood fiberboard may vary depending on the manufacturer. The standard size is usually 4 feet by 8 feet. Other sizes include 4 feet by 9 feet, 4 feet by 10 feet, 4 feet by 11 feet, and 4 feet by 12 feet. Custom sizes are also available upon request.

Q2: What are the grades of wood fiberboard?

A2: There are three main grades of wood fiberboard: low-density fiberboard, medium-density fiberboard, and high-density fiberboard. Low-density fiberboard is lightweight and has excellent thermal insulation. Medium-density fiberboard is durable and versatile and is commonly used in furniture and cabinetry. High-density fiberboard is very strong, dense, and ideal for applications requiring structural support, such as load-bearing shelves or countertops.

Q3: What are the common applications of wood fiberboard?

A3: Wood fiberboards are used in different applications. It is used in furniture construction, such as cabinets, drawers, and desktop surfaces. It is also used in home interior designs, such as wall paneling, and ceiling tiles. It can also be used to manufacture doors and door frames. It is also used in the automotive industry to create interior panels and components. Other applications include packaging, and acoustic panels.

Q4: What are the advantages of wood fiberboard?

A4: Wood fiberboard has many advantages. It is eco-friendly since it is made from waste wood products. It is also versatile and can be used in different applications. It is also smooth and has a uniform surface, which makes it ideal for printing and painting. It is also easy to work with and can be cut, shaped, and assembled using standard woodworking tools and adhesives.

Q5: What are the disadvantages of wood fiberboard?

A5: Despite having many advantages, wood fiberboard has some disadvantages. These include: it is prone to moisture damage, and it is less durable than other engineered woods. It is also susceptible to warping, and it has lower screw holding capacity.