(3089 products available)

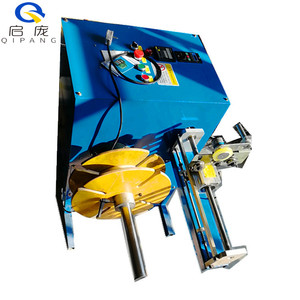

The steel wire bobbin is a cylindrical product used for holding wires and threads. This comes in different designs and shapes to suit various applications in distinct industries. The steel wire bobbin can be classified into two types based on function and structure.

Function

The main purpose of steel wire bobbins is to hold wires and threads. Therefore, it can be categorized based on its function as a wire holder and a thread holder.

Structure

Based on structure, steel wire bobbins can be understood as single-unit bobbins and bobbin sets. Single-unit bobbins are standalone units used to hold a specific type or color of wire or thread. They are commonly used in smaller-scale operations or for specialized tasks where only one type of wire or thread is needed. Bobbin sets, on the other hand, include multiple bobbins that can hold different types or colors of wire or thread simultaneously. These are often used in larger-scale operations or for applications that require frequent switching between different wires or threads.

Besides, wire steel bobbins can also be categorized based on material and size. The material determines the durability and strength of the bobbin. Bobbins made from steel are known for their strength and are often used in heavy-duty applications. On the other hand, plastic bobbins are suitable for lighter applications.

Additionally, wire bobbins can be categorized based on sizes. Steel wire bobbin comes in different sizes to meet the specific needs of distinct applications. Larger bobbins are commonly used in industrial settings where high quantities of wire or thread are needed. Smaller ones are more suitable for domestic or small-scale use.

Steel wire bobbins are made to hold varying steel wire gauges. For low-gauge wires, like 12 or 14, the bobbin is made with a wider diameter and a metal core. The wider diameter allows more coils of the wire to wind around it, and the metal core gives it stability, preventing it from bending under the weight of the wire. For higher gauges, such as 20 to 22, the bobbin may have a plastic core and a smaller diameter.

The bobbin also has a coil width. Low gauge steel that is heavy may have coil widths of about 8 inches. This allows wide spacing of the coils to prevent overlapping of the coils. However, with lighter and thinner gauges, the coil widths could be about 4 inches to 6 inches. The coil widths are necessary to prevent overlapping snags that could damage the wires.

The bobbin will also have flanges at both ends, and the flange diameter can be 8 to12 inches, and the flange is used to keep the steel wire in place, preventing it from slipping off the sides. The flange basically keeps the coiled wires tight.

It is important to keep wire bobbins in a dry storage area away from moisture. Steel is prone to rusting, and when it is exposed to a damp or wet environment, it can rust. Trying to restore wire bobbins that have rusted is close to impossible, as the wire's structural integrity is already damaged. Bobbin racks are usually placed in an area where the air circulation is great. However, if it cannot be placed in such an area, it should be treated with anti-corrosive coating on the part of the steel that is exposed to the air. This will create a layer that will resist the formation of rust.

When loading the bobbin onto the machine that will wind the wire around it, ensure that the wire is wound evenly. Poor winding can lead to wire tangling during the unwinding process. Tangling can cause mishaps and accidents during use and may damage the bobbin. Always ensure that the wire bobbin is wound evenly and uniformly.

Always ensure that the wire bobbin is wound evenly and uniformly. Further overlapping snags and tangles can be avoided, making it easier to maintain the wire steel bobbin.

Textile and Weaving Industries:

In the textile and weaving industries, wire bobbins are commonly used to house warp threads in looms. Heavy-duty Steel bobbins are utilized to ensure that threads remain taut and organized during the weaving process. Their durability makes them ideal for high-speed weaving environments where frequent thread changes and replacements are necessary. This ensures an uninterrupted weaving process.

Upholstery and Packaging:

In the upholstery and packaging industries, wire steel bobbins are frequently employed in sewing and stitching machines. These machines are used to execute sewing jobs that require a strong and reliable thread. Wire bobbins facilitate smooth and even thread feeding to stitching needles, which enables precise and efficient sewing operations. Additionally, wire steel bobbins help to hold packing tapes and sewing threads in packaging machinery. This enables the accurate and effective sealing and labeling of products.

Automotive and Assembly Lines:

In the automotive industry and assembly lines, wire steel bobbins play a critical role in holding various types of wires and cables used in manufacturing processes. They may hold welding wires, signal wires, or other specialized wires, ensuring that the wires are organized and easily accessible during assembly. This improves efficiency and productivity.

Farming and Agriculture:

Wire steel bobbins are used in the agriculture sector for various fencing and trellis applications. They can help organize and dispense fencing wire, making it easier for farmers to install or repair fences and supports for plants or crops. Hence, ensuring an organized agriculture operation.

Application:

Consider the intended application of the bobbin. Different industries and uses may require specific types of bobbins to hold, transport, or dispense wires. For example, fiberglass bobbin is preferable for industries that need to handle wires with insulating properties or specific handling requirements, such as for electrical wiring or certain manufacturing processes.

Material:

The choice of bobbin material is crucial as it affects the performance, durability, and compatibility with the stored wire. Select the material that aligns with the wire's needs and the handling conditions. For instance, plastic bobbins are lightweight and corrosion-resistant, making them suitable for various wires.

Design:

Choose a bobbin design that meets the handling and dispensing needs. Some designs offer easy wire access, while others provide stability during transportation. Ensure the design is compatible with the wire's size and quantity.

Durability:

Consider the required durability of the bobbin based on its use. Some bobbins need to withstand heavy handling and environmental exposure, while others are used in controlled conditions. Choose a bobbin that meets the durability needs to prevent damage and wire loss.

Compliance:

Check if the bobbin complies with any industry standards or regulations. Certain applications may require compliant bobbins to meet safety, environmental, or quality standards. Using compliant bobbins helps businesses adhere to required safety and operational standards, reducing the risk of regulatory violations and enhancing product safety and reliability.

Q1: How does the reel steel bobbin work?

A1: The wire steel bobbin functions as a supportive reel, holding and dispensing steel wire during processes such as manufacturing, construction, or fencing installation.

Q2: What are the benefits of using wire steel bobbins?

A2: Wire steel bobbins help organize tangled steel wires, allowing for easy dispensing. They also prevent wires from tangling, kinking, and damaging. Bobbins made of steel are very durable and can withstand frequent handling and accidental drops.

Q3: Are wire steel bobbins recyclable?

A3: Yes, they are typically made from recyclable steel material.

Q4: Can steel wire bobbins be used with other types of wires?

A4: Yes, as long as the size of the steel wire bobbin and the steel wire itself are compatible, wire bobbins can be used with other wires.