(69 products available)

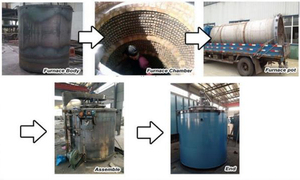

A well-type gas carburizing furnace is a kind of well furnace. According to the heating method, it can be divided into well-type gas carburizing furnace and well-type electric carburizing furnace. Well-type gas carburizing furnaces use natural gas or LPG as fuel, while well-type electric carburizing furnaces use electricity to heat coils. In addition, it also includes well-type air carburizing furnaces, well-type vacuum carburizing furnaces, and well-type salt carburizing furnaces following the different carburizing methods.With the same well furnace heats the workpiece by immersing it in a molten salt liquid. The solution is typically sodium nitrate and potassium nitrate. Well-type salt carburizing furnace has high strength and low alloy steel carbon. They're also known for having short carburizing times and great thermal efficiency.

According to the material, it can be divided into well-type steel carburizing furnaces, well-type cast iron carburizing furnaces, and well-type alloy carburizing furnaces. The well-type steel carburizing furnace is mainly designed to carbonize steel workpieces. A well-type cast iron carburizing furnace is primarily used to carbonize cast iron workpieces. The well-type alloy carburizing furnace is suitable for alloy workpieces. In addition, well-type carburizing furnaces can also be classified into small, medium, or large according to their specific sizes.

Well-type gas carburizing furnaces are available in distinct specifications according to industrial needs. The following table shows some examples of available specs for well-type carburizing furnaces.

Furnace Diameter

This describes how wide the well-type carburizing furnace is. Generally, the diameter ranges from 600mm to 1800mm, but custom models with up to a 3000mm diameter are available.

Effective Length

It describes how long the well-type carburizing furnace is. The effective length ranges between 1000mm to 4500mm, depending on the design. Custom lengths over 4500mm are also available.

Usable Temp. Range

This signifies the temperature range the well-type carburizing furnace can withstand. Typically, it ranges from 800 to 1150 degrees centigrade. Some models can even go as high as 1200 degrees centigrade.

Materials of Construction

Well-type carburizing furnaces are usually constructed with heat-resistant alloy steel. The materials can also withstand any aggressive environment or high temperature in the carburizing process.

Type of carburizing medium

Users can decide to choose the type of carburizing medium. This includes gas, solid, and liquid medium, to mention but a few.

It is very important to regularly maintain the well-type gas carburizing furnace. Doing this will increase its life span and also boost operational efficiency. The following suggestions will guide the furnace owner's regular maintenance routines.

A well type gas carburizing furnace is applicable in various industries that deal with metals and metal products. The most common metal carburizing furnace application is in the automobile industry. The automobile industry uses the carburizing furnace to harden various parts of the vehicle. For example, the furnace can be used to treat gears, axles, shafts, and bearing components.

The gear industry also extensively uses the well type carburizing furnace. Essentially, gears need to be tough and have a tough surface to enable them to withstand varying loads and stresses. Furthermore, the toughness also enables them to serve for extended periods without wearing out. The well type gas carburizing furnace is not limited to the mentioned industries. Many other industries use it to effectively heat and treat metals and metal products.

Another industry that can use the carburizing furnace is the aviation industry. The aviation industry extensively uses various types of steel, at least 80%, to manufacture different parts of an aircraft. A well type carburizing furnace, among others, is used to treat and strengthen the steel and make it ready for use to manufacture parts of the airplane. Any weak or soft metal parts in an airplane can pose a threat to the lives of people who use it. Therefore, it is very crucial to ensure that only strong and durable metal parts are used to make the airplane.

Another possible application of the carburizing furnace is in the weapon industry. Weapons and weapon components need to be tough to support various pressures and forces when in use. For example, weapon components like gun barrels, firing pins, and bolt lugs are manufactured using the carburizing furnace to ensure they are tough, durable, and strong.

Intended Purpose:

The primary purpose of a well type carburizing furnace must be established before anything else. Different carburizing methods exist, and selecting the furnace that aligns with one's desired approach is crucial.

Material Compatibility:

Different furnaces are compatible with distinct materials. It's vital to ensure that the chosen carburizing furnace can effectively treat the intended material.

Production Volume:

Consideration must be given to the amount of material to be processed. Whether a high-capacity production line or a small-scale batch processing facility is in use will determine the size and capacity of the furnace needed.

Treatment Temperature and Atmosphere:

The required temperature and atmospheric conditions for carburizing may vary depending on the material and desired properties. It's important to select a carburizing furnace that can achieve the necessary temperature and maintain the appropriate atmosphere throughout the treatment process.

Furnace Efficiency:

Energy efficiency and carburizing rate of the furnace play crucial roles in determining the costs associated with its operation. Choosing a high-efficiency furnace can help minimize energy consumption and reduce treatment time, leading to cost savings in the long run.

By carefully considering all of the above factors, it's possible to make an informed decision when choosing a well type gas carburizing furnace that meets specific needs and requirements.

Q1: What are the trends in carburizing furnace technology?

A1: Recent well type gas carburizing furnace trends focus on energy efficiency, environmental compliance, automation, and high-performance materials. Industrial carburizing furnaces are becoming more energy efficient by using waste heat recovery, which reduces operational costs. Carburizing furnaces must meet strict environmental standards, leading to the adoption of systems for cleaning emissions and reducing the environmental impact. Automation is also a trend in carburizing furnace technology, with more industrial carburizing furnaces being equipped with automated controls and monitoring systems to improve accuracy and consistency in carburizing processes. In addition, the increasing demand for high-performance materials in the automotive and aerospace industries is driving the development of carburizing furnaces that can process carburizing materials at high temperatures.

Q2: How does a well type gas carburizing furnace decrease environmental impact?

A2: Well type gas carburizing furnaces decrease environmental impact by using emission control systems such as scrubbers, filters, or electrostatic precipitators, which can capture or treat pollutants before they are released into the atmosphere. In addition, many well type gas carburizing furnaces have been improved to use less gas and electricity, which decreases greenhouse emissions, thereby improving the environment.

Q3: What is the difference between a well carburizing furnace and a pit carburizing furnace?

A3: The design of the carburizing furnace is horizontal. Well type carburizing furnaces are more suitable for processing small batches of workpieces. The pit carburizing furnace is vertical and cavernous. It is more suitable for processing large workpieces or high production volumes.

Q4: What are the advantages of the well type gas carburizing furnace?

A4: The well type gas carburizing furnace has many advantages. It can enhance the hardness and wear resistance of workpieces, thereby prolonging their service lives. In addition, the well type carburizing furnace also has energy-saving and low gas emission advantages, which can help enterprises reduce costs and improve sustainable development.