(20676 products available)

High-density polyethylene (HDPE) is a thermoplastic polymer that is highly versatile in its industrial applications due to its robustness and chemical resistance. HDPE pipes are widely used in various industries for fluid transportation. Properly joining these pipes is critical for a secure and leak-proof installation. An HDPE welding machine is an essential tool for this purpose. It allows for the fabrication and connection of HDPE pipes with precision and strength. The HDPE pipe welding machine uses specialized techniques to fuse HDPE pipes, ensuring a seamless and durable joint. It is commonly employed in construction, water management, and industrial piping systems for its efficiency and reliability in creating strong, long-lasting connections.

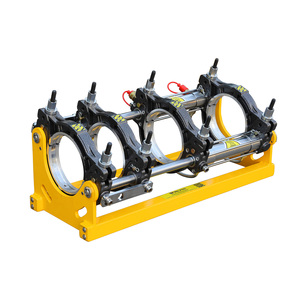

There are several common types of HDPE welding machines, each catering to specific welding needs. The butt fusion welder is designed for joining two HDPE pipes of the same diameter by heating the pipe ends and then pressing them together. Electrofusion welding involves the use of an electrofusion machine, which applies an electric current to heat a specific HDPE fitting, enabling it to fuse with the pipe. Socket fusion welding utilizes a socket fusion machine to heat both the pipe and fitting, creating a strong joint when the molten material cools. Moreover, hot air welding is a technique where a hot air gun is used to melt the HDPE surfaces, which are then pressed together to form a bond. The choice of welding machine HDPE depends on the project requirements, pipe sizes, and environmental conditions.

HDPE welding machines find extensive applications in various industries and projects where HDPE pipes are utilized. In water distribution systems, these machines are crucial for joining pipes securely, preventing leaks and ensuring a continuous flow of water. In the natural gas sector, HDPE pipes are used for their corrosion resistance and flexibility, and the welding machines enable the construction of safe and reliable gas distribution networks. Additionally, in the industrial sector, HDPE pipes are employed for transporting chemicals and other fluids, and the precise joints made by the welding machines help maintain the integrity of these pipelines. Furthermore, in the agricultural sector, HDPE pipes are utilized for irrigation systems, and the welding machines play a vital role in creating leak-free connections, ensuring efficient water distribution in fields. Lastly, in the mining and construction industries, the durability of HDPE pipes combined with the strength of the joints made by the welding machines make them suitable for diverse applications, such as dewatering, drainage, and slurry transportation.

HDPE welding machines offer several advantages that contribute to their widespread adoption in the industry. They are characterized by their ability to create strong and durable joints, ensuring leak-free connections that are essential for fluid transportation. The efficiency of these machines is another notable advantage, as they enable quick and precise welding, reducing installation time and labor costs. Moreover, the versatility of HDPE welding machines allows them to be used in various welding techniques, such as butt fusion, electrofusion, and socket fusion, providing flexibility for different project requirements. Additionally, the user-friendly nature of these machines, coupled with their reliability, makes them accessible to both skilled professionals and operators, contributing to seamless pipe installations. Lastly, the environmental sustainability of HDPE pipes and the joints made by these machines further enhance their appeal in construction and infrastructure projects, aligning with the growing focus on eco-friendly practices in the industry.