(2385 products available)

The choice of a 300A welder depends primarily on the welding methods required. The common types of welders include:

This type of welder utilizes Insulated Gate Bipolar Transistors to convert DC power into different voltage levels required for various welding jobs. They are famous for being extremely efficient and generating little heat during operation compared to other types. They are particularly useful for welding thin metals where control over current is vital.

This welder can operate in a few modes; it can do welding by using gas, and it can also do the current work of direct welding. These dual capabilities allow for flexibility when working with different materials. For example, AC is ideal for aluminum and stainless steel, while DC is used for thicker aluminum and silicon steel.

These welders use generators to produce electricity required for welding. They are mostly used in places where power supply is guaranteed to be unavailable. Welder generators are preferred for heavy quality and construction work.

These welding machines are based on metal inert gas welding and utilize inverter technology to regulate the current. These machines are lighter portable and more affordable than conventional MIG welders.

These machines can operate at both 110V and 300V power supply. Such flexibility makes them versatile for both home and commercial welding. Their TIG capability is desirable for precision work, giving clean, strong welds.

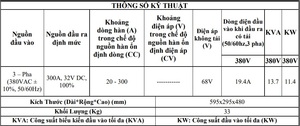

Different kinds and makes of welders come in different specifications. Some are more suited to certain jobs than others.

To protect against rust, corrosion, or any other physical damage, store the welder in a clean, dry place. If working outdoors, avoid direct exposure to weather elements. Keep the welding area free of clutter to minimize the risk of tripping and to ensure easy access to tools.

The Welder 300 A machines are meant to be used in jobs that are harder than those usually considered for at-home DIY.

With a 300 amp output, these welders can handle heavy-duty welding jobs. They can weld not just thin metal but even medium and some thick metal. Their ability to run larger electrodes means faster work without stopping to cool.

This is a machine in which wafers are bonded using heat to create integrated circuits. Manufacturers use welder machines to perform bonding at high speeds. Their 300 amp output enables work on many wafers within a short time frame.

Established in 1805, George Fischer of Switzerland has worked in the domain of system piping for liquid and gas since then. They also manufacture other associated machines, tools, and equipment, including solenoid valves for electrical control. These valves help regulate fluid movement within systems, and the welders are used to construct or repair pipeline installations.

In frame construction, a frame means the structural skeleton of a building. This is the part that supports the roof and the walls. The welders are used to join steel or iron members, providing strength and support to the structure.

Construction refers to building structures and systems. Fixing means all repairs done, such as patching up leaks or replacing damaged parts. The welders in construction projects are used to connect steel beams and create strong joints. In fixing, they patch up holes in pipes or reinforce weak areas.

Pipelines transport water, gas, oil, and other liquids. Installations involve laying down new pipes or connecting existing ones. The welders in pipeline installation create the necessary connections between pipes and ensure they are durable enough to transport heavy materials. They are commonly used for patching, repairing rusted areas, or installing new sections.

For metal fabrication, metals are bent, cut, and assembled into parts or products. They are used to create custom metal components for buildings, vehicles, and machinery. Maintenance is critical to ensure these welders remain in good condition for accurate and safe welding. People in metal fabrication rely on them to perform many metalworks.

Vehicle repairs involve fixing cars and trucks. This may mean replacing old parts or repairing the damage. Welders In vehicle repair are used to patch up holes in car bodies and reinforce frames. They help make old trucks functional and less risky.

One 300-watt amp does not fit all. The choice depends on the specific welding needs and preferences.

Stick welding is great for outdoor work and on dirty or rusty metal. It's hard and doesn't need lots of power or special gear. MIG welding is simpler and faster and works well on thin to mid-thick metal. It's easier for newcomers because the machine does part of the work. TIG welding is slow and needs more focus, but it's perfect for thin metal and shows.

Check what power sources are available where the machine will be used. 300 amp welders that run on 110V can be used at home and by novices. Those that need 300V are better for major projects that require professional-grade tools.

For short tasks like vehicle parts, a lower rating is fine. Pick higher ratings for long jobs like frames that work for hours. Longer cycles mean less downtime.

Digital inverter welders are lighter and easier to move than big generator welders. Choose portability for tight spaces or when the welder needs to be carried often.

Stick welders are among the least costly. MIG and TIG welders with advanced features cost more. Inverter welders are more affordable than conversion welders with impressive transformers.

Big brands like Lincoln and Miller are known for trustworthy gear. Their top welders are often chosen for commercial jobs. Lesser-known brands may offer quick fixes but could lack durability in demanding settings.

A1: The 300 amp welder works on Steel as thick as 1/2 to 1 inch. The heat will penetrate more to get through these thick metals. It works best at higher settings for solid, durable welds.

A2: A 7018 Stick Welder uses E7018 electrodes. The 'E' means it works well with both AC and DC power. This makes it flexible for many kinds of welding jobs.

A3: The 300 amp MIG welder needs 220-volt power, which is the standard outlet for all home major appliances. This level of amps is sufficient for all household welding jobs.

A4: A 300amp MIG welder can work on steel up to 1-inch thick. For aluminum, it tackles 3/8 inch without a problem. These settings let it smoothly handle both metals with ease.

A5: AC TIG welding alternates current flow, which is great for aluminum. DC TIG has steady current, which works wonders on tougher metals like steel for strong, smooth joints.