(139 products available)

Welded webforge steel grating is a durable and popular product used in many industries. It comes in different types that cater to various industries and applications. Here are some of the common types of welded webforge steel grating:

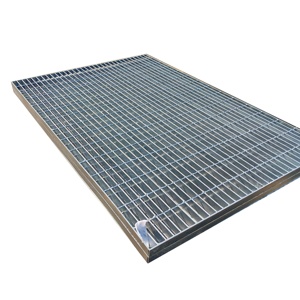

Welded Steel Grating:

This type of grating is constructed using load-bearing bars and cross bars. The load-bearing bars are heavy steel bars. They are available in various sizes and shapes. The load-bearing bars are welded to the cross bars. The cross bars are smaller steel bars. They are welded perpendicular to the load-bearing bars. This creates a strong and stable steel grating. This type of welded steel grating is popular. It is used in industrial flooring, walkways, platforms, and drainage covers.

Welded Aluminum Grating:

This grating is made from aluminum. It is lightweight but still has high strength. The welded aluminum grating is resistant to corrosion. It is suitable for use in areas near water. It is also used in applications where weight reduction is important. For example, the welded aluminum grating is used in shipbuilding and marine applications.

Welded Fiberglass Reinforced Plastic (FRP) Grating:

This type of grating is constructed using a composite material. The composite material consists of fiberglass strands embedded in a resin matrix. The welded fiberglass reinforced plastic grating is lightweight. It has a high strength-to-weight ratio. It is also resistant to corrosion. It is ideal for use in harsh chemical environments. This includes waste treatment facilities and chemical processing plants.

Heavy Duty Steel Grating:

This type of grating is constructed using heavy gauge steel bars. They are capable of supporting high loads and heavy foot traffic. The heavy-duty steel grating is popular. It is used in industrial applications. For example, it includes power plants, steel mills, and heavy machinery areas. This grating provides a long-lasting and low-maintenance flooring solution.

Welded steel grating offers a variety of features that provide numerous applications in different industries. Some of the key features include:

High Strength and Durability

Welded steel grating is renowned for its exceptional strength and durability. It is manufactured from heavy-duty flat steel bars, also known as load-bearing bars. These steel bars are welded together using cross bars or twisted bars. This creates a grating structure capable of bearing heavy loads and high traffic. Therefore, this type of grating is ideal in applications that require a high degree of strength. For instance, in industrial flooring, platform walkways and stair treads.

Robust Design

The design of welded steel grating is quite robust. It features closely spaced load-bearing bars and cross rods. This design offers a variety of benefits. For instance, it provides excellent load distribution and enhanced airflow. Additionally, it allows the passage of light and water. The robust design of welded steel grating makes it suitable for applications in various sectors. Such as construction, manufacturing, oil and gas, mining, and wastewater treatment.

Corrosion Resistance

Welded steel grating is manufactured from different types of steel. For instance, carbon steel, galvanized steel, and stainless steel. Due to this, it possesses exceptional strength and durability features. As a result, it can withstand difficult environmental conditions. Such as high-impact blows, extreme temperatures, and corrosive elements. This makes it a suitable option for both internal and external applications.

Safety and Slip Resistance

Safety is a key consideration in any application involving foot traffic or the movement of personnel and equipment. Welded steel grating provides enhanced safety features. For instance, it offers excellent slip resistance. This is due to the grating surface that allows for traction, reducing the risk of slips and falls. Additionally, the open structure of the grating permits water to drain away quickly. This helps to prevent the formation of slippery surfaces.

Easy Installation and Maintenance

Welded steel grating is quite easy to install. It comes in pre-fabricated panels that can be cut and fitted to specific dimensions and layouts on site. This type of grating is also simple to maintain. Its durable construction ensures that it retains its structural integrity. It also withstands harsh conditions and requires minimal maintenance over its lifespan.

Welded steel grating is used in many industries and applications. Some common scenarios include:

Walkways and Platforms

Welded steel grid plates are often used in walkways and platforms. They provide a strong and stable surface for people to walk on. They also allow for safe movement of pedestrians and workers. The open design of the grating allows water, debris and other materials to pass through. This helps to reduce slip hazards. The platforms and walkways are commonly used in industrial areas, commercial buildings and construction sites.

Industrial Flooring

Welded steel gratings are used as flooring in many industries. They offer high load-bearing capacity and durability. This makes them suitable for areas with heavy foot traffic and machinery. The steel grating flooring also provides traction and prevents slips and falls. This ensures the safety of workers and machinery.

Stair Treads and Risers

Welded steel gratings are also used in stair treads and risers. The grating surface offers excellent slip resistance. This improves the safety of people using the stairs. The open design of the steel grating allows light to pass through. This enhances visibility in low-light areas. The stair treads and risers are commonly installed in factories, warehouses and outdoor staircases.

Safety Barriers

Safety barriers are made from welded steel grating. The barriers are strong and durable. They offer structural integrity and long-term performance. The steel grating construction allows for visibility and ventilation. This is important in areas where air circulation is needed. The safety barriers are used in industrial settings, commercial properties and construction sites.

Drain Covers

Welded steel gratings are also used as drain covers. They allow water to flow freely into the drain. This prevents water from pooling and reduces slip hazards. The drain covers are strong and can withstand heavy traffic. They are suitable for use in streets, parking lots and industrial areas.

HVAC Covers

Welded steel gratings can be used as HVAC covers. They allow air to circulate freely and improve ventilation. The open design of the grating reduces clogging and debris buildup in the HVAC system. The steel grating covers are easy to install and maintain.

Many factors influence the selection of a suitable steel grating for a certain application. Consider the following points when choosing the ideal webforge steel grating for your project:

Steel Grating Type

There are different types of steel gratings. Load-bearing steel grating is ideal for heavy traffic areas, such as industrial walkways and platforms. It can withstand high loads and offers excellent slip resistance. Bearing steel grating is used in applications where light to medium loads are expected, such as HVAC systems and drainage. It is lightweight, cost-effective, and has good airflow. Meanwhile, fiberglass reinforced grating is used in corrosive environments like chemical plants and wastewater treatment facilities. It is non-conductive, lightweight, and corrosion-resistant.

Application

Applications impact the design and specifications of steel grating. For outdoor environments, steel grating with high corrosion resistance is preferred. This includes galvanized steel or aluminum grating. For industrial settings, load-bearing capacity and slip resistance are crucial. This makes welded steel plate grating or serrated grating suitable. In residential applications, aesthetic appeal and lightweight characteristics are important. Hence, ornamental steel grating or light-duty steel grating can be used.

Bar Configuration

Bar configuration influences the performance and appearance of the steel grating. Close-bar configurations offer higher load-bearing capacity and better slip resistance. This makes them ideal for heavy industrial applications. They also provide better safety in high-traffic areas. On the other hand, wide-bar configurations allow for better light and airflow. This makes them suitable for areas where illumination and ventilation are required. They reduce the need for artificial lighting and improve air circulation.

Load Requirements

The weight of objects that the grating will support determines the type of grating to use. Higher loads require more robust solutions, such as thicker bars or closer spacing. This ensures safety and structural integrity. Calculate the expected load using the manufacturer's load tables. This ensures the selected grating meets or exceeds the anticipated load. Regularly reviewing load conditions ensures the continued suitability of the grating.

Environmental Conditions

Webforge steel gratings are affected by different environmental conditions. These include humidity, temperature, and exposure to chemicals. Choose steel grating materials with high corrosion resistance for humid and coastal areas. Galvanized or stainless steel gratings are ideal. In areas with high temperatures, it's important to consider the thermal expansion properties of the grating. Opt for steel grating types that minimize expansion and contraction. This ensures safety and structural integrity.

Q1. How Is Welded Webforge Steel Grating Maintained?

A1. It's maintained by regularly cleaning it to get rid of debris and inspecting it for any signs of rust or loose welds.

Q2. How Does One Prevent Corrosion On Welded Webforge Steel Grating?

A2. One can prevent corrosion by galvanizing the grating during fabrication or applying a polymer coating.

Q3. What Are The Load Bearing Capabilities Of Welded Webforge Steel Grating?

A3. The load bearing capabilities depend on the thickness of the bearing bars and the spacing. Close-set thicker bars can support heavier loads.

Q4. Can Welded Webforge Steel Grating Be Customized?

A4. Yes, it can be customized. Steel grating can be made in different sizes, bar spacings, and finishes to suit specific needs.

Q5. What Is The Installation Process For Welded Steel Grating?

A5. Installation involves welding the grating onto a steel frame. It's important to ensure the frame is level and the grating is securely welded.