(985 products available)

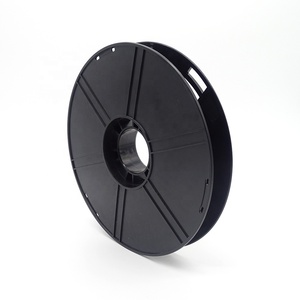

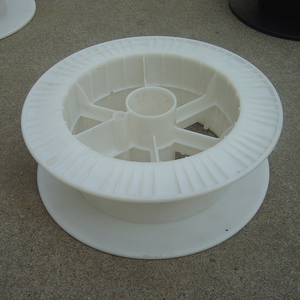

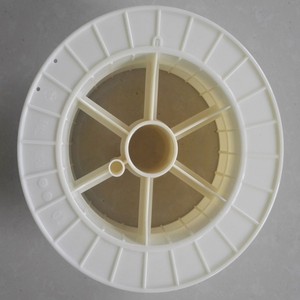

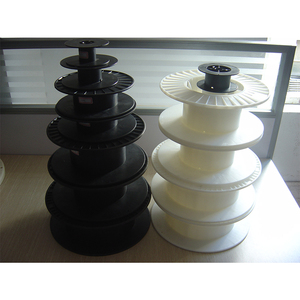

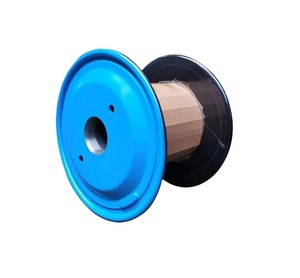

A welded bobbin is a cylindrical device that provides support for textile thread, fiber, wire, and other such material during weaving, knitting, embroidery, and stitching. The welded bobbin can hold these materials until they need to be unspooled and used in a specific application. Apart from the welding components, these bobbins usually consist of a tubular body with flanges on both sides.

Interestingly, there are different types of welded bobbins depending on the material and application:

Plastic Welded Bobbins:

Plastic welded bobbins are bobbins made of plastic, which is a non-metallic, synthetic material that's malleable, durable, and capable of being molded into various shapes. Usually, commonly used plastics include PP (Polypropylene), PC (Polycarbonate), and ABS (Acrylonitrile Butadiene Styrene). PP is renowned for its toughness and resistance to chemicals and impacts. On the other hand, PC is recognized for its high impact resistance, strength, and optical clarity. Also, ABS combines light weight, strength, and impact resistance, making it an excellent choice for products that require durability. Plastic welded bobbins offer a lightweight alternative to their metal counterparts, reducing the overall weight of the sewing machine parts.

Aluminum Welded Bobbins:

The aluminum welded bobbin is a cylindrical object used to hold the lower thread in sewing machines, particularly in multi-needle, embroidery machines. Its main role is to assist in the embroidering process by providing a place for the lower thread to be kept. Aluminum is a soft, lightweight, silvery-white metal that is both tough and resistant to corrosion. Aluminum welded bobbins are lighter than steel welded bobbins. This makes them easier to use and handle, reducing operator fatigue during prolonged sewing tasks.

Steel Welded Bobbins:

Like aluminum welded bobbins, the steel welded bobbin's primary purpose is to store the lower thread in sewing machines. Steel is an alloy made by combining iron with small amounts of carbon and other elements to improve its strength and durability. Steel welded bobbins are tougher and more durable than aluminum bobbins, providing long-lasting performance even in heavy-duty sewing applications. Additionally, aluminum bobbins are non-magnetic, making them distinct from steel bobbins, which are magnetic. Magnetic objects are those that maintain a force field strong enough to attract or repel other magnetic materials. Welding magnets can easily stick to steel welded bobbins, making it very easy for welders to handle the job.

Inspect the bobbin:

Check for any wear and tear, undue breaks, or corrosion on the outer surface of the bobbin. Pay close attention to the unwound part to ensure the stability and safety of the welding process.

Clean the bobbin:

Cleaning is needed when there are impurities or residue but avoid using corrosive materials that can damage the bobbin.

Repair the bobbin:

If the bobbin is damaged, it needs to be repaired in time. Welding is suitable for small breaks or cracks, and adhesive is better for low-strength areas that are easily worn out. A new bobbin is recommended if the damage is extensive.

Welded bobbins are helpful in many areas and can be used for various tasks. Here are some common industries and applications where these bobbin holders are typically used:

When buying welded bobbins for sale, customers will first look at their needs based on the type of equipment and how much wire is needed per weld. They may also consider the preferred method of welding and the desired quality of the welds. After this evaluation, customers will be able to choose the correct bobbin size.

Next, customers should choose reliable suppliers. They can read reviews and ratings from previous customers to find a supplier with a proven track record of delivering quality products on time. It's also important to confirm if the supplier caters to large orders and offers shipping services to their location.

Customers should also negotiate for competitive prices if making a bulk order. The price should correspond to the product’s quality. When ordering welding machine bobbins online, customers should ask for samples to evaluate their quality before making a large order.

Lastly, customers should be aware of the latest trends in welding bobbins. The market now offers welding bobbins that support multiple welding processes. These are ideal for businesses that use different welding methods. Furthermore, many welding bobbins have features that improve feed accuracy, such as spool designs that minimize wire spin and drag. Customers should also be aware of the eco-friendly welding bobbin options made from recycled materials.

Q1: What is the difference between a bobbin and a spool?

A1: A bobbin refers to a cylindrical object that holds thread or wire. It can also describe the smaller version of spools. Bobbins are usually designed to fit within a sewing machine or hand sewing kit. A spool is generally bigger than a bobbin and comes with a wider base to hold a larger amount of thread, wire, or cable.

Q2: What are the advantages of welded stainless steel bobbins?

A2: Stainless steel bobbins are preferred due to their strength, corrosion resistance, and low maintenance. Stainless steel can withstand extreme temperatures and is ideal for applications that require a sterile environment because it does not harbor bacteria. Welded bobbins are more durable, less likely to break, and can withstand the rigors of daily use.

Q3: How does one properly store welded bobbins?

A3: It is best to keep the bobbins in their original box to avoid dust, debris, or damage. Store them in a cool, dry place away from direct sunlight and heat. Organize the bobbins by size and keep them vertically like spools to prevent tangles and twists.