(9210 products available)

Fabric is produced using a combination of yarn and weaving parts looms.

The primary components of the loom weave are as follows:

Heddles

Heddles are lightweight cords or wires that support the warp threads. Each warp thread is attached to a heddle, allowing it to be lifted or lowered by the heddle frame.

Epidiaphragms

The epidiaphragm, also termed the anepends, is the object that constrains the weft threads to keep the trailing threads inserting stable. This limitation may be made of wood, plastic, or metal, and typically has a slot for each row of fabric. After being inserted, the weft yarn traverses through the opening, and it is then restricted by removing the epidiaphragm device.

Heald Frame

The heald frame is the frame that holds the heddles. The warp threads are lifted to form a shed (the opening between the threads). The size and configuration of the sheds directly influence the fabric's thickness and weave pattern.

Shuttle

The shuttle is a small object used to insert the weft thread between the warp threads. Traditionally, it was a wood piece shaped like a boat, but contemporary ones may be made of plastic or metal, with various kinds and dimensions to insert a different kind of weft yarn.

Beater

The beater places the weft yarn into the loom weave. It has a metallic or synthetic stick known as the reed. During the weaving process, the weft yarn is pressed down to form the fabric. The beater's speed, force, and overall action influence the fabric's density, tightness, and quality.

The Loom Frame

Every loom has a frame that covers the whole machine. The design, size, and makeup of the frame determine how the rest of the loom will be made and how it is going to be used.

Sley

It refers to the process of inserting warp threads into the loom to form the fabric's width. The loom parts were set based on the beater's number of slots or openings. This method was very important because it determined the cloth's density and pattern.

Loom Joinery

Weaving looms joinery refers to the way different loom parts are connected. Generally, bolts, screws, and other fastenings clamp one part to the other, ensuring there is a sturdy and well-knit weaving structure.

The weaving parts looms fabriques include classic hand looms, jacquard looms, and modern shuttle looms, which weave tapes, belts, and narrow textiles. Every weaving loom has its specs depending on the age and type. Below are the general specifications along with the maintenance requirements:

Size and weight:

A huge loom like the Jacquard loom can weigh several tons because it has huge, complex machinery to handle the intricate woven fabrics it creates. Smaller looms for home weaving are lighter and more portable. Beam looms, for instance, weigh between 300-400 pounds. Shuttle looms used for weaving narrow woven fabrics tend to be smaller and lighter, usually weighing around 125 pounds or less, making them easier to maneuver and operate.

Material:

Textile looms use various metals, hardwoods, and composites. The heavier metal looms need more structural support, so the beams and frames will be made of strong steel or cast iron to handle the stress and tension of weaving. A Jacquard loom features die-cast aluminum shuttles and plastic harnesses. Most modern weaving looms for narrow weaves use lightweight and stronger materials, such as space-age polymers like nylon, to create an efficient and compact weaving apparatus.

Weaving width:

As mentioned earlier, wider looms are bigger and take up more space. They will also have long warp beams, a large weaving width of up to 150 inches, and a hefty frame. Such colossal looms are left in one stationary place, while smaller ones can be rolled about to different work areas. The shuttle or the weft carrier in a narrow-weaving loom are usually under 16 inches, which makes it more portable, and the fabric it produces is denser.

Power source:

Large weaving machines run on electric power, usually a three-phase power source, whereas manual looms may be foot-powered or hand-powered. A Jacquard loom is probably going to need more electric power than a simple shuttle or hand loom, which may have parts that run on electricity but still rely on human feet to push paddles to move it.

Tension system:

The tensioning systems among various looms can be very different. The heavier looms need stronger bearings, hydraulic tensioners, and spring tensioners to manage the tension from the heavy beams and warp threads. An example would be bearing houses like pillow blocks that secure the beam along with other internal features that are designed to manage the tension smoothly and evenly. Older looms, such as Jacquard looms, may have managed the tension through a shuttle box and reed. Tensioners on modern looms for weaving tapes and trims may use a variety of technologies to efficiently strain fiber, like a low-backlash motorized drive.

The maintenance of all types of weaving looms includes cleaning, lubricating, and adjusting loose parts. Thorough maintenance is needed every week or at more frequent intervals for parts subjected to constant friction. These include lubricating the shuttle boxes, reeds, and warp beams. In addition, all moving parts across different looms should be regularly oiled and adjusted to ensure smooth operation. Any quick-release clips, clasps, ropes, and harnesses should be checked for wear or tear and replaced if necessary. Before any maintenance, the electrical parts and components should be switched off for safety.

The primary purpose of weaving loom parts is to assist in the weaving process. They are commonly used in the textile manufacturing industry along with the entire loom, which constitutes the main weaving machine. Weaving loom parts such as shuttles, heddles, reed combs, bobbins, and replacement heddle plates and reeds are used in all types of looms, whether they are large industrial weavers or small, easy-to-use ones in domestic settings.

As the use of woven textiles spread across different cultures and continues to do so; most countries have come to depend on various woven goods, agricultural fields, and bordered territories, especially when it comes to the fashion and interior décor industries. A huge market volume around the world depends on woven materials and fabrics.

Weaving parts are not limited to textile production only. They are also crucial in creating intricate tapestries and a host of other architectural fabrics used to make up essential items like:

Many expert weavers look for specialized tools that can help them make more intricate patterns. These are usually found on fine looms and include things like the loom reed hook, the beat-in reed, the shed stick, and the weaving sword.

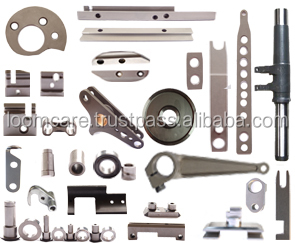

When looking for weaving parts for sale, it is important to consider items that buyers will be interested in purchasing. Some of the key parts that make a complete loom but can also be bought independently are:

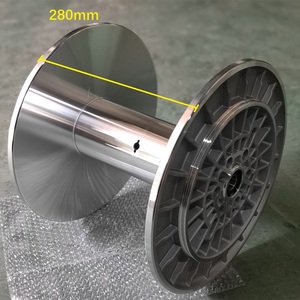

Warp Beam:

The warp beam is where the longitudinal yarns (the warp) are wound from. Many weavers will have several warp beams with different yarns on them so that they can easily switch between different patterns and designs with ease.

Heddles:

The Heddles are the lines that separate the warp yarns, usually by a thread that is used to pass through a designated eye. Heddles will usually be sold in sets based on the loom's design. Different looms will use various types of heddles. To give customers more options, consider selling a selection of heddles made from different materials.

Reed:

The reed is a comb-like structure that helps space out the weft yarns and pushes them together to form a woven fabric. The width of the reed space will determine how thick the final woven product will be. There are different types of reeds, including flat, spring, and rag reeds. Many weavers will have several different reeds based on the fabric they want to create, so consider carrying a variety of different reeds in your inventory.

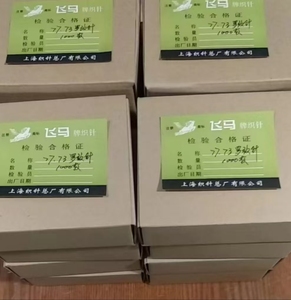

Drum:

The drum is where the pre-shed yarn is rolled up. It is also known as the false shedding loom. It is an integral part of looms that use the drum to create a weave.

Warping Board:

The warping board is used to create an accurate and secure arrangement of the warp yarns before they are placed on the loom. It acts as a frame, and numerous boards with a variety of pegs are available. Usually, weaving enthusiasts will use the warping board to facilitate the warping process when preparing for weaving projects. Consider carrying boards in various sizes to appeal to a wide range of customers.

Shuttles:

The shuttle is a bobbin or a device used to hold the weft yarns and insert them into the loom (usually called the shuttle pathway). Many weavers will use a great variety of shuttles for different kinds of yarn weights and sizes.

Q1. What are the main parts of a loom and their functions?

A1. The main weaving parts of looms and their functions include the warp beam, weft carrier, heddles, harnesses, shuttle, reed, cloth beam, and take-up mechanism. The structure, movement, and combination of these loom parts help to weave the threads into fabrics.

Q2. What materials are looms made of?

A2. Weaving looms are usually made of wood and metal alloys. Wooden looms are common in hand-weaving tools like table looms, floor looms, and strap looms. Various types of metals are used to make an alloy that is sturdy and light for industrial weaving looms, such as shuttle looms, jacquard looms, and dobby looms.

Q3. How do loom parts work together to create fabric?

A3. In a loom weaving machine, all parts work together. The warp beam rotates to release the vertical threads. The heddles separate the warp threads. The weft carrier moves horizontally across the separated warp threads, weaving in the horizontal threads. The reed beats the weft threads against the warp threads, closely woven together. The cloth beam stores the finished fabric. The take-up mechanism helps to release the woven fabric while the un-woven threads are taken up.