Introduction to Wash Conveyors

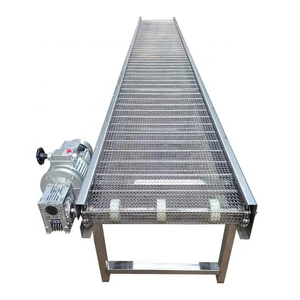

A wash conveyor is an essential piece of equipment in various industries, especially in manufacturing and food processing. Designed to integrate seamlessly into production lines, this technology efficiently transports items through a washing system, ensuring cleanliness and hygiene. Companies leverage wash conveyors to enhance operational efficiency while meeting safety standards and reducing labor-intensive cleaning processes.

Types of Wash Conveyors

- Static Wash Conveyors: These are stationary systems typically used for larger items that require thorough cleaning without motion interference.

- Dynamic Wash Conveyors: These systems move the items through a washing station, significantly speeding up the cleaning process in high-volume operations.

- Wet Wash Conveyors: Primarily used for food processing, they utilize high-pressure water jets to remove contaminants effectively.

- Dry Wash Conveyors: These convey cleaning agents and air jets to remove debris without using excessive water, ideal for sensitive equipment.

Function and Features of Wash Conveyors

- Efficient Cleaning: Wash conveyors enable consistent cleaning across production batches, reducing the risk of contamination.

- Integrated Design: Many models feature modular designs, allowing businesses to customize them based on the size and nature of items being washed.

- Automation Capabilities: Equipped with sensors and control systems, wash conveyors can automatically adjust water pressure and flow rates for optimal cleaning.

- Eco-Friendly Operation: Many modern systems are designed to minimize water usage and recirculate used water, promoting sustainable practices.

Applications of Wash Conveyors

- Food and Beverage Industry: Used to wash fruits, vegetables, and equipment, ensuring compliance with health standards.

- Manufacturing: Ideal for cleaning parts and components in automotive and electronics manufacturing to ensure maximal performance.

- Agriculture: Essential for washing equipment and tools, helping to maintain hygiene and prevent cross-contamination.

- Pharmaceuticals: Critical in ensuring that tools and equipment are free from contaminants, adhering to strict regulatory guidelines.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4