(252 products available)

There are different types of W 19 4 steel gratings, depending on how they are constructed and what they are used for.

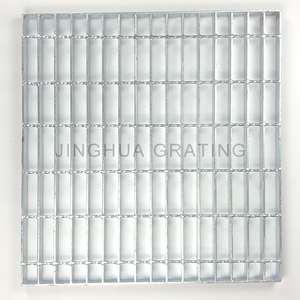

Bar grating

This type of steel grating is made up of long steel bars, which are called bearing bars. They run parallel to the direction of traffic. The crossbars are installed perpendicularly to the bearing bars. They provide support and make the grating safe to walk on. The bar grating is welded together. This makes it a one-piece construction that is very stable. It can support heavy loads without bending or breaking.

Expanded metal grating

These steel gratings are made from a single piece of metal. The metal sheet is cut and stretched to form a diamond pattern. The open spaces between the diamonds are the same shape as the diamonds. This design allows water, light, and air to pass through easily. Expanded metal grating is lightweight and durable. It is used in different applications where support and drainage are needed.

Slip-resistant grating

This type of steel grating is designed for areas that are wet or where there is a lot of foot traffic. It has a rough surface that prevents people from slipping and falling. Slip-resistant steel gratings are used in factories, parking lots, and staircases. They keep people safe in places where they could easily fall.

Press-locked grating

These steel gratings are made from hot-rolled steel bars. The bars are pressed together under high pressure until they lock. No welding is done. This makes the grating look more uniform and neat. Press-locked steel gratings are very strong. They last for a long time and need little maintenance.

Swaged grating

Swaged steel grating is made by forcing the crossbars through the bearing bars. They are locked in place without welding. The bars are locked very tightly. This makes swaged steel grating very stable and able to support heavy loads. It also has a lightweight design.

Steel grid flooring has numerous applications, especially in construction projects. Its features and functions are fundamental to the safety and strength of any structure.

Durability

Steel grates are durable. This durability is due to their resistance to impact, corrosion, and deformation. They can withstand any harsh environmental conditions. They can also withstand heavy loads and traffic. This makes them a preferred choice for many construction projects.

Load bearing capacity

Steel grid floors allow for the distribution of loads over a larger area. This is due to their structural configuration. This lattice design enables load bearing and stability. The load bearing capacity makes them suitable for walkways, platforms, and industrial flooring.

Ventilation and drainage

Steel grid floors have open spaces between the bars. These spaces allow for the free flow of air and water. This prevents the accumulation of moisture and promotes ventilation. Proper drainage and ventilation reduce the risks of slip and corrosion.

Safety features

Steel grid floors have numerous safety features. These features make them safe for use in any construction project. Their slip-resistant surface provides traction, reducing the risk of falls. The open grid pattern also enhances visibility and reduces trip hazards. Additionally, the strength and stability of steel grids minimize the risks of structural failure.

Modular design

Steel grid floors have a modular design. This design consists of standard sizes and shapes. This makes cutting, welding, and installation easy. The modular design simplifies the replacement and maintenance of damaged sections. This helps to reduce long-term costs.

Aesthetic appeal

W 19 4 steel grating comes in different styles, finishes, and patterns. This enhances the visual impact of any structure. They can also be customized to fit any design requirements. Their aesthetic appeal integrates functionality with design in architectural projects.

Steel grating is used in different industries for walkways and platforms because of its sturdiness, longevity, and anti-slip characteristics. The applications are numerous, from construction sites to industrial facilities and power plants. Here are some of the most common application scenarios:

Construction and Walkways:

Steel grid is a common feature in construction sites. The site is usually filled with debris, sharp objects, and uneven terrain. Using steel grid allows workers to safely navigate the site and carry out their duties without injuries. It also allows for the easy passage of light and water.

Platforms and Stairs:

Steel grid makes for a great application of platforms and stairs in construction. It is durable, anti-slip, and allows the easy passage of water and air. It is also lightweight and makes for easy installation.

Industrial Application:

There are different types of steel grating for industrial applications, such as heavy-duty steel grating, galvanized steel grating, and fiberglass grating. The construction of factories and industries involves the use of steel grid. The reason for this is that the grid can support heavy machinery and equipment, is anti-slip, and allows the easy passage of water and air.

Power Plants:

Power plants use steel grids in almost all their construction areas, from walkways and platforms to heavy-duty applications. This is because they can support the weight of large machinery, provide ventilation and light, and allow for the easy passage of water without creating pooling or slipping hazards.

Architectural Applications:

Steel grid is increasingly being used in architectural designs and applications. This is because it allows for a modern, industrial aesthetic look while providing functionality, such as structural support, ventilation, and light transmission.

When choosing steel grating for sale, buyers should consider the following tips for selecting the right product:

Load Capacity and Span:

Consider the load capacity of the steel grating. Check the manufacturer specifications to see the load that each type of steel grating can carry. Also, check the span or distance between the support beams. The span affects the load capacity. A shorter span between support beams increases load capacity.

Environmental Conditions:

Check the environmental conditions where the steel grating will be installed. Will it be installed indoors or outdoors? If it will be installed outdoors, will it be exposed to extreme temperatures, high humidity, or chemicals? These environmental conditions affect the performance and durability of the steel grating.

Safety Standards:

Consider the safety standards of the project. Check the building codes and regulations. Consult with engineers to determine the best steel grating for safety. This will ensure that the project is safe and the steel grating meets all the required standards.

Slip Resistance:

Check the slip resistance of the steel grating. This is very important in high-traffic areas or where water or oil is present. Consult with manufacturers to determine the best slip-resistant steel grating.

Maintenance Requirements:

Consider the maintenance requirements of the steel grating. Some types of steel grating require more maintenance than others. If the steel grating will be installed in a high-traffic area, it will require more maintenance.

Aesthetic Appearance:

For some projects, the aesthetic appearance of the steel grating is very important. If the steel grating will be used in an area where appearance is important, consider the color and design of the steel grating.

Q: What does the ""W"" mean in W19-4 steel grating?

A: ""W"" means the type of welded steel grating. The W type of steel grating is resistance spot welded. The bearing bars and cross bars are welded together to form a steel grating that is resistant to corrosion and rust.

Q: What are the common finishes for W19-4 steel grating?

A: There are three common finishes for W19-4 steel grating. They include mill finish, hot-dip galvanizing and painted finish. Mill finish is the raw appearance of the steel grating. Hot-dip galvanizing is the anti-corrosion treatment of the steel grating. It is the steel grating's standard finish. The third finish is paint coating. The bearing bars and cross bars are coated with paint to prevent corrosion and rust.

Q: What are the load-bearing capacities of W19-4 steel grating?

A: The load bearing capacity of W19-4 steel grating varies. It depends on the spacing and thickness of the bearing bars. The load capacity can range from 1000 lbs to 8000 lbs and above. Steel grating suppliers and manufacturers offer load tables. The load tables help buyers choose suitable steel grating with the right load capacity for their applications.

Q: What are the standard thicknesses of W19-4 steel grating?

A: The standard thickness of bearing bars is 0.38"" to 0.5"" The thickness of cross bars is 0.38"" The thickness of the bearing bars and cross bars affects the strength and load capacity of the steel grating. The higher the thickness, the greater the load capacity.

Q: What is the typical lead time for W19-4 steel grating?

A: The typical lead time for W19-4 steel grating is between 2 to 4 weeks. The lead time can be shorter or longer. It depends on the order size and the supplier's production capacity. Some suppliers offer same-day delivery for small order sizes.