(281 products available)

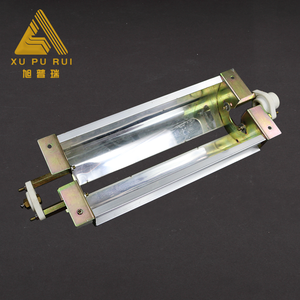

A UV lamp aluminum reflector is used in conjunction with a UV lamp to enhance the intensity of UV light for various applications. These applications can include UV curing, sterilization, and other industrial or commercial uses of UV light. The reflector is designed to focus and direct the UV light emitted from the lamp, providing a more efficient and effective output.

UV lamps are aluminum reflectors that come in several different types, including;

Aluminum Coated Reflectors

This type of UV lamp aluminum reflector has a simple design. It consists of a base material, which is usually aluminum. The aluminum is coated with a reflective material that enhances its ability to direct UV light. The coating can be anodized aluminum or a special reflective coating designed for UV light. These UV lamp aluminum reflectors are widely used in various UV lamp applications. For instance, they are used in UV curing lamps, UV sterilization lamps, and other UV lamps requiring light direction and focus.

Polished Aluminum Reflectors

This type of reflector is made of aluminum that is highly polished to enhance its reflectivity. The polished surface allows for maximum light output and intensity. They are commonly used in applications where high-intensity UV light is needed. For example, they are used in industrial UV curing systems and applications that require a high degree of UV light for curing or drying materials.

Anodized Aluminum Reflectors

Anodized aluminum reflectors are treated through an anodic oxidation process. The process creates an aluminum oxide layer that is usually reflective and durable. These reflectors are resistant to heat and corrosion. They are popular in applications where UV lamps operate at high temperatures or in harsh environments.

Specialty UV Reflectors

These are unique types of UV lamp aluminum reflectors specifically designed for certain applications. For example, some reflectors are designed to focus on particular UV wavelengths for specific curing processes. Others are built for UV sterilization applications and can effectively direct UV-C light for disinfection purposes.

A UV lamp reflector is an aluminum part placed around the UV lamp. It reflects and distributes UV light over the surface that needs curing. Here are the features and functions of a UV lamp aluminum reflector:

Enhances curing

The primary purpose of the UV lamp reflector is to enhance the curing process. It reflects UV light towards the area where the UV gel or coating is applied. This results in an even distribution of UV light. An enhanced curing process leads to a smooth finish and consistent adhesion.

Aluminum construction

The UV reflectors are made of aluminum. This metal is lightweight, durable, and has high thermal conductivity. The aluminum construction ensures maximum UV light reflection.

High reflectivity

The UV lamp reflector has a high reflectivity coating. It directs the UV light towards the target surface. This increases the efficiency of the UV lamp. It also minimizes the amount of UV light wasted.

Improves lamp efficiency

By reflecting UV light, the aluminum reflector improves the efficiency of the UV lamp. It ensures that nearly all the emitted UV light is directed towards the curing surface. An improved lamp efficiency saves energy. It also results in quicker curing times.

Customizable design

The UV lamp aluminum reflectors come in different designs and sizes. This allows them to be tailored to specific UV lamp configurations. A properly fitted reflector maximizes the curing efficiency.

Easy maintenance

The aluminum reflectors have a smooth and non-porous surface. This makes it easy to clean and maintain them. Proper maintenance ensures the reflectors maintain their reflectivity and provide optimum performance.

Heat dissipation

The UV lamp aluminum reflectors are designed to dissipate heat away from the curing surface. This prevents overheating and damage to sensitive materials. Effective heat dissipation prolongs the lifespan of the cured products.

UV lamp aluminum reflectors are used in different industries. Here are some common usage scenarios:

Nail Curing

UV light aluminum reflectors are commonly used in nail salons. The UV reflectors help to cure gel nail polishes by providing UV light. The gel nails dry quickly and are durable when they are exposed to UV light. Also, different gel nail polishes can be cured simultaneously due to the even UV light distribution from the reflector.

Printing Industry

The printing industry uses UV lamp reflectors to cure inks. The UV reflectors help to dry or cure inks quickly. This is important for offset, flexographic, and screen printing. The UV reflectors provide consistent curing. Thus, it helps produce high-quality printed materials with smooth finishes. Also, the quick curing process increases the overall printing speed.

Adhesive Bonding

In industries where adhesives are used, UV lamp reflectors are employed. The reflectors are used to cure UV-sensitive adhesives. The curing process helps to create a strong and clear bond. This is done in applications such as lens manufacturing, glass bonding, and electronic component assembly. Consistent UV light ensures that the adhesive cures uniformly. This results in a high-strength bond.

Coating Applications

UV lamp reflectors are used to cure protective coatings. For instance, varnishes and sealants in wood finishing and furniture manufacturing. The UV reflectors enable a fast and energy-efficient curing process. This creates a hard and chemical-resistant coating. The industries that require durable and high-gloss coatings utilize UV reflectors. Examples are automotive, aerospace, and high-end consumer goods.

Biomedical Applications

UV lamp aluminum reflectors are used in the medical field. For example, they are used to disinfect tools and medical devices. The reflectors provide UV-C light which helps to eliminate pathogens. The reflectors are also used in phototherapy treatments for skin conditions like psoriasis and eczema.

Food Industry

Some food processing plants utilize UV lamp reflectors. The reflectors are used to disinfect and purify water. They are also used to disinfect surfaces and extend the shelf life of certain food products. For example, tomatoes and other fruits.

Cosmetics

UV lamp reflectors are used in the cosmetics industry. The reflectors are used to cure certain cosmetic products. For example, gel-based cosmetics. Also, they are used in tanning salons to enhance UV-A tanning treatments.

When purchasing a UV lamp with an aluminum reflector, buyers should consider several crucial factors to ensure they stock a product that will meet the needs of their customers. Here are some of them:

Output and Wavelength

Different applications require various UV lamp output levels and wavelengths. Buyers should get lamps with outputs of 200 to 300nm, which are ideal for curing UV-sensitive materials. They should also get lamps with different outputs to cater to various applications, such as those for gel nail curing, which require a wavelength of about 365nm. They should also get models with aluminum reflectors that enhance intensity and uniformity for optimal curing.

Design and Portability

Depending on the customer's needs, buyers should get UV lamps with designs suitable for various setups. For instance, models with a compact design are ideal for buyers who will stock lamps for customers looking for options that are easy to move and fit into limited spaces. On the other hand, more powerful models are suitable for professional salon setups.

Energy Efficiency

Buyers should get energy-efficient UV lamps with aluminum reflectors to reduce energy consumption. Energy-efficient options are also more environmentally friendly. These options will also enable their customers to reduce their operational costs, making their businesses more profitable.

Durability and Build Quality

To ensure longevity and optimal performance, buyers should get UV lamps made with high-quality materials. They should get models with robust construction capable of withstanding frequent use. Moreover, they should get models with aluminum reflectors because they are resistant to UV radiation damage and high temperatures.

Compatibility

To ensure the UV lamps they get are compatible with various UV curable materials, buyers should get different models. They should also ensure the lamps are compatible with the typical setups of their customers. For instance, buyers can stock handheld lamps, and those are ideal for portable use and larger models suitable for professional settings.

Ease of Use and Maintenance

Buyers should get UV lamps that are easy to use. For instance, options with simple controls and clear instructions. They should also get easy-to-maintain models. These can include options that come with cleaning kits and have simple maintenance procedures.

Q1: Are UV lamps with aluminum reflectors safe to use?

A1: UV lamps are generally safe when used properly. It is important to follow the manufacturer's instructions and take appropriate safety precautions when using UV lamps.

Q2: Can UV lamps with aluminum reflectors be used for purposes other than curing?

A2: UV lamps are primarily designed for curing. Using them for other purposes is not recommended unless the manufacturer specifies it.

Q3: How do I choose the right UV lamp for my needs?

A3: When choosing an UV lamp, consider the intended use, the type of materials to be cured, and the required curing time. Also, consider the lamp's power output and the size of the curing area.

Q4: What are the maintenance requirements for UV lamps and aluminum reflectors?

A4: UV lamp maintenance requires regular cleaning of the aluminum reflector surface to remove any built-up debris or contaminants. This ensures optimal light output. It is also important to follow the manufacturer's maintenance guidelines.