(579 products available)

Ready to Ship

Ready to Ship

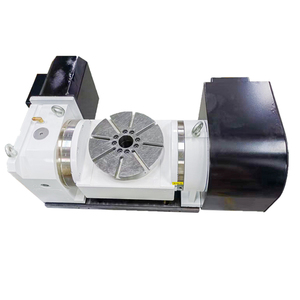

Usually, CNC rotaries get categorized based on their axis and working environment. Here are the most common types of used CNC rotary tables available for sale.

By axis

Typically, a CNC machine with a single rotary table is mainly axis-paced. It introduces a new movement along the X, Y, and Z axes. The 3-axis CNC rotary tables work perfectly for projects that entail packaging simple work. On the other hand, CNC 4-axis rotary tables have an additional A-axis of rotation. Therefore, they can be used to achieve more complex jobs, such as engraving and molding cylindrical objects. This is easy to achieve through automated and unattended machining. The used 5-axis CNC rotary table lacks a fixed A-axis and instead has both A and B rotational axes. Such a table offers extreme flexibility and precision when working on an object. As a result, the rotary is the most popular choice for machinists working on astronomy, jewelry, and medical industry applications.

By working environment

Generally, open-frame CNC rotary tables suit businesses that work on various workpiece sizes. The models allow easy setup for different projects. Additionally, they provide excellent access to workpieces from nearly all directions. Therefore, there will be minimal interruptions to the machining process. However, the models may not always offer adequate part security and protection. This could leave used machines vulnerable to environmental threats and accidents.

On the contrary, enclosed CNC rotary tables usually have a protective cover around the work area. It significantly helps to safeguard the workpiece from any outside interference. Also, the machine operator is safeguarded from any injury that could arise from getting into contact with the moving parts.

Universally, the specifications of the used rotary table CNC vary depending on different types, models, and applications. Therefore, it is crucial always to look out for specifications corresponding to one's needs or requirements.

Dimension and weight:

Typically, the dimensions and weights of used rotary tables for sale affect the setups' capacities and also the space of working. In most cases, with larger dimensions and heavier weights, the tables can handle setups that are larger or heavier, along with providing more stability. For instance, a sizable rotary table like a 24-inch CNC rotary table would have a dimension of 1050x900x400mm with a weight of around 70kg, while a smaller one like a 4-inch CNC rotary table would have a dimension of 250x210x130mm and a weight of around 4.5kg.

Accuracy

Accuracy is a crucial specification that determines how precise a rotary table can position a setup. In most cases, it is indicated by a certain number of arc seconds or tenths of a millimeter. For example, a used CNC table may have an accuracy of ±5 arc seconds, translating to a positioning precision of ±0.01 mm.

Max weight capacity

It is common to find specifications of used CNC table rotarys indicating the maximum load or weight they can rotate. The weight capacity varies from one model to another, depending on table size, design, and motor strength. For instance, smaller rotary tables like the 4-inch CNC type can take up to 5kg maximum weight, while larger ones like 12-16 inches can go up to 60 kg.

Drive system

The drive system of a CNC rotary table controls the movement and rotation of setups. In most cases, it influences accuracy, speed, and also the capacity to carry weight. Some common types of drive systems are servo motors, direct drives, stepper motors, and belt drives.

Caring for and maintaining a CNC rotary tables ensures they operate smoothly and safely, despite withstanding harsh working environments. As discussed earlier, rotary CNC tables feature various types and designs, meaning that the maintenance tips can vary. Nonetheless, some general maintenance practices apply, regardless of the type or model.

A rotary table is a crucial part of any CNC machine. It allows the machine to perform more complicated tasks in a single setup by providing additional axes of movement.

Some possible applications of CNC rotary tables include the following:

Assess Workpiece Size and Weight Capacity

When buying a used CNC rotary table, check whether it can hold workpieces of a specific size and weight. Rotary tables come in different sizes. Pick one that suits the dimensions of the workpieces usually utilized in production. If a rotary table has insufficient weight capacity, it may not support heavier workpieces, leading to operational issues.

Determine the Required Axis Count

Consider the complexity of workpieces and the need for axis count. Axis count describes the number of programmed axes on a rotary table. Compare cost and performance by matching required axis counts with workpiece demands. Typically, two axes suffice for simple rotational jobs. However, advanced projects involving friction, gears, or large cylinders may need four or more axes. Prioritize tables with an affordable number of axes that still meet project needs.

Check for Significantly Worn Components

Examine key parts of the rotary table critically. Normal use causes some wear, but excessively worn components can lead to problems. Reduced precision, instability, and safety hazards are possible with severely worn parts. Avoid tables with egregious wear levels. Testing major components first helps prevent future repairs. Taking these precautions improves investment quality and prolongs service life.

Evaluate Condition of Drive System

Assess the drive mechanism—motor, gearbox, and belts—responsible for moving and positioning the rotary table accurately. A well-functioning drive allows precise motion control, while damaged drives hinder operation. Choose a table with an intact and operable drive system. Functional driving ensures trouble-free integration into existing CNC setups for seamless machining workflow.

Port and Connectivity Options

Ensure that the used CNC rotary tables have compatible ports and connectivity options. Check for the communication protocols supported by the rotary table, such as Ethernet or Fieldbus. Look at the plug-ins used to connect it to the CNC controller. Verify if an adapter or converter is required for linkage. Be certain that the table can communicate smoothly with other components in the automation system without link disruptions.

Q1: What are the current trends in the CNC rotary table market?

A1: The market shows a growing preference for automated and high-precision CNC rotary tables, driven by industrial demand for efficiency and accuracy in machining processes. Additionally, the surge in 3D printing applications is propelling the need for advanced rotary tables, particularly those capable of handling larger workpieces and higher rotational speeds.

Q2: How does a CNC rotary table increase productivity?

A2: A CNC rotary table boosts productivity by enabling continuous machining operations, reducing setup times through automatic workpiece rotation, improving tooling efficiency, and facilitating unattended machining during automated routines.

Q3: What is the lifespan of a CNC rotary table?

A3: The lifespan of a CNC rotary tables can vary widely based on usage, build quality, maintenance, and operating conditions. Generally, a durable rotary table with regular maintenance can last between 10 to 20 years or even longer for heavy and critical equipment.

Q4: Can a CNC rotary table be used with any CNC machine?

A4: No, a CNC rotary table cannot be used with any CNC machine. It must be compatible with the specific type, size, and control system of the CNC machine. However, most used CNC rotary tables are designed to be compatible with standard CNC milling machines and lathes and can be readily integrated with them.

Q5: Does a used CNC rotary table offer the same level of precision as a new one?

A5: Provided the used rotary table is well-maintained and has not sustained any severe damage, it can still offer comparable precision to new tables. Nonetheless, some parameters like rigidity, load-carrying capacity, repeatability, etc., might be affected by age. When considering a second-hand CNC table, it's prudent to check its condition thoroughly and assess its operational capabilities.