(345 products available)

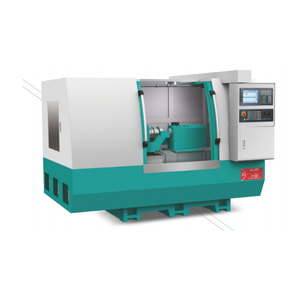

A used CNC cylindrical grinding machine is combined with a computer numerical control (CNC) system for enhanced automation and precision. However, there's a distinction between machines with or without a CNC. An important variety involves the use of center and centerless grinding techniques. While specific models aren't explicitly categorized by technique, they may be internally delineated based on their grinding methods and versatility.

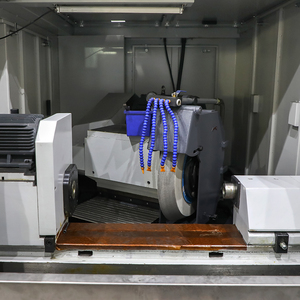

Generally speaking, the machine is designed to grind and refine cylindrical objects or surfaces of irregular shape and are made physically or chemically round. The grinding is usually done with the help of a horizontal or vertical wheel, assisted by other wheels and tools. The machines may be used in the industry to sharpen cutting tools, such as drill bits, which generally have a complex geometric shape. Other applications of cylindrical grinders include core, internal, and external cylinder, sphere, and face grinding, as well as the fine lapping of cylindrical geometries.

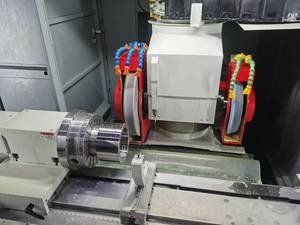

The technician operates a cylindrical grinder by fixing the workpiece over two centers, one of which is movable to allow for proper alignment and support of the object in question, or the object may be held by a carrier furnished with a suitable drive mechanism. The part does not require to be exactly round for it to be ground, but it does need to have a central axis about which it rotates. Centerless grinders are easier to operate since they allow for a continuous-throughput production process.

A conventional cylindrical grinding machine lacks automated controls and relies on manual input to position and grind workpieces. In contrast, a CNC cylindrical grinding machine has a computer-based automated control system, allowing for high-precision grinding of complex shapes. The cylindrical grinding machine is conventionally used with the machine operator standing on top and working on the different cylinders of the object being ground.

A center cylindrical grinder has two centers, one of which is fixed, and a sharp metallic tool that is pressed along the surface of the cylinder to be ground. A centerless grinder uses constant velocity to grind parts as they move through the machine. The constant velocity is achieved by friction from the grinding wheel and the support of the V-shaped jaws that hold the workpiece.

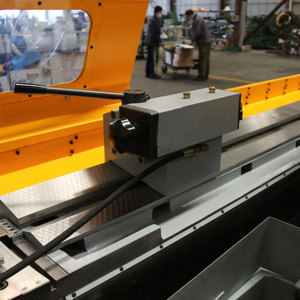

The grinders vary greatly in features, including full automation and touch-screen controls, the country's best-selling products for all used to grind, like solid bars, alloy bars, aluminum profile bars, etc., and industrial-grade safety features protecting those operating the machines and small children and other novices. Other techniques include the external grinding machine that is pressed against the external surface of the object to be ground, the internal grinder that works on the internal surfaces of objects, and the universal grinder, which, as the name suggests, works the same as a normal grinder but at a higher level of efficiency and precision.

Whether CNC or not, it is common to find profile cross, plunge, and peripheral grinding types in a cylindrical grinder machine. Generally, a CNC cylindrical grinder machine is a sophisticated tool that stands out because new computers support the machine and its operation. There is also a distinction between not only the machine shape and the types of objects it may be used to work on—metallic, plastic, or otherwise—but also the precision with which the cylindrical object needs to be ground. The degree of sophistication required may also differ according to particular industry-grade standards.

Regular inspection of key components and assemblies of the grinding machine should be carried out to check their working condition. The following parts should be inspected on a priority basis during the scheduled approach and usage:

A used CNC cylindrical grinder can perform a variety of tasks that can provide multiple usage scenarios for different industries and applications.

Grind complex parts with higher accuracies:

A use CNC cylindrical machine can be used to grind complex parts that have 3D profiles and shapes. Without the need for multiple setups, this can be done with higher accuracy and greater precision. As a result, better-manufactured parts with intricate designs are produced.

Automated operations:

Cylindrical grinding machines used CNC can have their labor-intensive procedures automated. Parts can be machined, set up, and unloaded automatically using a CNC cylindrical grinder with a robotic loader or an integrated part conveyor. This automation improves the entire manufacturing process's efficiency, productivity, and precision.

Higher parts throughput and faster production:

`CNC cylindrical grinding machines used may automate operations, increase parts throughput, and accelerate production. The cylindrical CNC grinder can grind complex parts with higher accuracy and allow for quicker changeovers and setups. This process leads to faster production and increasees efficiency and productivity on the manufacturing floor.

Machine parts from different materials:

A cylindrical grinder CNC can grind different types of metals and even plastic. It can machine parts made of brass, carbon steel, stainless steel, alloy steel, tool steel, tempered steel, high-carbon steel, aluminum, synthetic rubber, engineering plastic, nylon, and polytetrafluoroethylene (PTFE). The only thing that needs to change to suit different kinds of materials is the grinding wheel.

Mold machining:

A cylindrical CNC grinder machine is an ideal tool for precision grinding of injection molding cavities, core cylinders, and other mold components. This is therefore an ideal choice machine for the plastic industry. It makes it easy to create smooth and shiny mold surfaces, reducing the need for manual polishing. For better production efficiency, the machine can also be used for the preparation of mold materials.

Machining various types of parts:

A CNC cylindrical grinder can also be used to machine different parts like shafts, rods, sleeves, spindles, hydrauliuc cylinders, reamers, drills, taps, threading tools, normal, right, and left gears, flywheels, crankshafts, flywheels, worm shafts, worms, splines, ball screws, threaded rods, weaver wheels, and music records, etc. The only limitations to what this machine can grind are the part's geometry and the grinding wheel's size.

Several factors need consideration when choosing a used CNC cylindrical grinding machine for sale. They all boil down to the needs of the buyer's business and what the grinding machine has to offer.

Q1: What is a used CNC cylindrical grinder?

A1: A cylindrical grinder machine is used to grind, sharpen, and polish materials of circular shapes. CNC grinders are automatically controlled by computers, which gives them greater efficiency and accuracy. A used cylindrical grinder is a second-hand item that has already been used but may still be functional and able to perform the same tasks as a new one.

Q2: What are the benefits of buying a used CNC cylindrical grinding machine?

A2: A used cylindrical grinder presents a cost-effective solution for those on a tight budget. Its capability to deliver the same level of functionality as a new device can make it a financially prudent choice for investment.

Q3: What are the risks of buying a used CNC cylindrical grinding machine?

A3: A used cylindrical grinder may have undisclosed damage, leading to functional problems or a shorter lifespan. In addition, there is no warranty or after-sales support to rely on.

Q4: How do suppliers ensure the quality of used CNC cylindrical grinders?

A4: Reliable suppliers will usually refurbished used grinders, repair them, and put them through a quality testing process to ensure they are functional. They may offer warranty support and after-sales services as well.