Introduction to Types of Crucibles

A crucible is an essential tool in various industrial applications, particularly in metalworking and chemistry. Designed to withstand extreme temperatures, crucibles are utilized for melting, holding, and transporting molten materials. Understanding the types of crucibles available can significantly enhance your workflow by selecting the right one for your specific needs. This comprehensive guide delves into the different types of crucibles, their features, applications, and advantages to help you make an informed decision.

Types of Crucibles

Crucibles come in various types, each designed for specific materials and conditions. Here are some of the most common types:

- Graphite Crucibles:

- Excellent thermal conductivity and high resistance to thermal shock.

- Ideal for melting non-ferrous metals such as aluminum, brass, and gold.

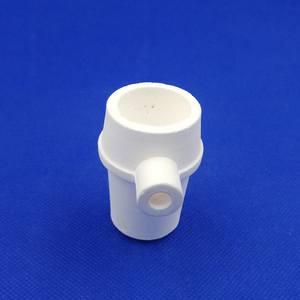

- Ceramic Crucibles:

- Made from materials like alumina and zirconia, offering high melting points.

- Suitable for applications in laboratories and metal casting.

- Metal Crucibles:

- Often made from cast iron or stainless steel, providing durability and heat retention.

- Commonly used in high-temperature processes like casting and forging.

- Silica Crucibles:

- Made of high-purity silica, these crucibles are perfect for laboratory applications.

- Used for analyzing metals and glass at extreme temperatures.

Applications of Different Types of Crucibles

The diverse types of crucibles are applied in numerous sectors. Here are the primary applications:

- Metalworking:

- Crucibles are pivotal in melting metals for casting, forging, and molding.

- Graphite and metal crucibles are preferred for their insulating properties.

- Laboratories:

- Ceramic and silica crucibles are widely used in laboratories for chemical reactions and studies.

- Providing superior heat resistance, they allow for precise experimental processes.

- Jewelry Making:

- In jewelry production, graphite crucibles are commonly used for melting precious metals.

- They enable artisans to create unique and intricate designs.

- Glass Production:

- Silica crucibles play a critical role in the glass-making process.

- They are utilized to melt raw materials at high temperatures to form glass products.

Benefits of Using Different Types of Crucibles

Choosing the appropriate type of crucible brings numerous advantages:

- Durability:

- High-quality materials ensure that crucibles can withstand repeated use and extreme conditions.

- Thermal Resistance:

- Each type is optimized for specific temperature ranges, enhancing operational efficiency.

- Cost-Effectiveness:

- Selecting the right crucible reduces wastage of materials, saving time and money in production.

- Versatility:

- Different types handle various substances, making them suitable for diverse applications across industries.