Types of tractor rotary hay rakes

A tractor rotary hay rake is used to gather cut hay into windrows for drying and harvesting. Farmers can choose from different designs and styles of hay rakes based on their preferences, farm sizes, and hay types. Here are some of the commonly used types of rotary hay rakes:

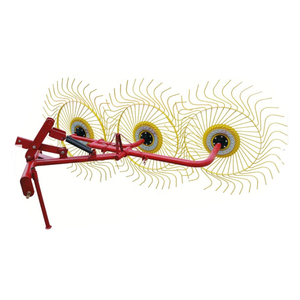

- Rotary rake: This rake gathers small sections of cut forage and then fluffs it up into a windrow. Rotary rakes can be towed behind tractors or raked by those attached to the three-point hitch of a tractor. Those towed behind are suitable for larger farms, while compact versions that can be hitched are meant for small areas. Rotary rakes are faster than wheel rakes, and they don't damage the crop. They have rotating rake heads that sweep forage into windrows. The number of rake heads on a rotary rake determines how much area will be covered, and the heads are usually spaced closely to prevent any forage from being missed.

- Disc rake: A disc rake is a type of rotary rakes where circular discs with curved tines are attached to a frame and evenly spaced. The discs rotate to lift the hay from the ground and then flip it to form windrows. The lifted flipped hay dries faster. Disc rakes are available in three-point hitch models and pull-behind models, and they are suitable for flat terrain free from debris. Farmers with large areas can cover more with a disc base because they have large areas, unlike wheel rakes.

- Pneumatic rakes: This type of rake uses air pressure to lift flattened hay. The drilling pistons create enough air pressure to raise the hay. Pneumatic rakes are suitable for large fields where different rake types cannot be used. This includes tall grasses and lots of open space. They are fast and will reduce the number of times the crops will be disturbed. A disadvantage is that air compressors are necessary for this type of rake, and they can be difficult to maintain.

- Frontal rakes: Also called a frontal filed inverter, this machine is attached to a tractor's three-point hitch and tows behind the tractor. It rakes the hay in front of itself and then inverts the forage to the ground in a backward motion. This forward operation allows the hay to be gathered faster, and more areas can be covered quickly. Because of its size and heavy weight, this type of rake requires a large tractor with sufficient horsepower to operate.

- Wheel hay rake: A wheel hay rake has several wheels with curved tines mounted on an arch. The wheels rotate to gather the hay and flip it to form windrows. This type of rake works best in rough and uneven terrain. Farmers who intend to gather hay infrequently and don't mind getting into a more extended period compared to using other winder rakes can opt for a wheel hay rake. It is usually affordable and will get the job done at a lesser cost.

Specifications and maintenance of tractor rotary hay rakes

Specifications

- Overall dimensions: The overall dimensions of a tractor rotary rake may include width, depth, and height. Typical dimensional parameters are about 2.5m in width, about 2m in depth, and about 1.5m in height.

- Weight: The weight of the machine is about 300kg. Heavy rake head weight can ensure good ground holding and efficient raking performance.

- Matched horsepower: The rotary rake requires a specific horsepower to be fully utilized. The proper matching of tractor horsepower ensures efficient and stable operation. Its compatible horsepower is usually between 30 and 50 horsepower.

- The working width: The working width of the rotary rake determines the coverage and working efficiency of the machine. The greater the raking width, the higher the productivity during hay raking. Typical working widths range from 2.5m to 4.2m.

- The number of rake teeth: The number of rake teeth affects the raking quality and efficiency. More rake teeth provide greater coverage and a more thorough raking process. The number of rake teeth is usually between 40 and 60.

Maintenance

- Clean: Clean the entire machine, especially the rake teeth and transmission parts, to remove grass residue and dirt. Clean the machine thoroughly with water and a mild detergent, followed by wiping and airing it.

- Check for wear and tear and damage: Regularly inspect the rake wheels, rake teeth, chain belts, and other parts for signs of wear and damage. If there is any loss, they need to be replaced as required.

- Lubricate: Apply lubricant to all moving parts, such as transmission chains and bearings, to ensure smooth operation, reduce wear, and enhance working efficiency.

- Adjust: Periodically adjust the positions of the rake teeth and the height they reach to ensure proper ground contact and coverage. Also, adjust the working width according to different conditions to improve efficiency.

- Pay attention to electrical and hydraulic systems: If the rotary rake has electrical or hydraulic systems, these should also be maintained periodically. Inspect wiring, connectors, hoses, and hydraulic cylinders, ensuring the systems function properly and are free from any leakage.

- Regular maintenance: Establish a regular maintenance schedule and promptly perform routine maintenance tasks such as replacing lubricants, cleaning filters, etc. This will keep the machine in good working condition.

Scenarios of tractor rotary hay rakes

-

Livestock farms

A livestock farm uses a tractor rotary hay rake to rake hay. The hay rake collects hays into windrows, making it easier for the farm to harvest and store them for animal feed. It also helps manage grassland by raking excess crop residue back onto the land to decompose and provide nutrients.

-

Lodging grain fields

After an unexpected heavy rain, the operator uses the tractor rotary rakes to lift the grazed and lodged grains. The operation restores the plant's upright position, making it easier to harvest. It also reduces crop losses and improves field tidiness.

-

Extension services

An extension service can use a tractor hay rake to carry out on-farm demonstrations within the community. The demonstration will showcase proper hay-making techniques to small-scale farmers. It may include tips on the right timing for raking, effective maintenance of grasslands, and efficient raking methods.

-

Community pasture

A community pasture uses a tractor rotary rake to collect and gather hay from different plots. The hay is for communal livestock or storage for future use during the dry season when grass is scarce.

How to choose a tractor rotary hay rake

Purchase a rotary rake after careful thought and investigation. Focus on the kind of rake first, taking into account aspects like how it will be used, the kind of grassland, and the tractor's matching power. Choosing the appropriate working width is crucial since it affects field efficiency and the number of passes required to complete a task. A width that suits the typical area worked and the machine's power is essential for economic use.

The rake's design should match the kind of forage being handled. Select a floating design for uneven fields or ground where hay may be stuck. Additionally, take the hay quality into account. A ground-driven rake may be adequate for handling high-quality hay on level terrain but insufficient if using low-quality forage or uneven fields.

Pin rakes have a simpler structure and are easier to maintain. At the same time, belt rakes can offer gentler treatment for forage but are more complex and may require more maintenance. Assess the ease of maintenance and repair services available for the chosen rake. Consider also the replacement parts' availability. Severe weather or flooding can lead to a greater likelihood of need since rotary rakes are more susceptible to damage.

Consider whether the rake's comprehensiveness will be examined prior to purchase. Limited thoroughness when comprehensiveness is not an option can be cost-effective. Whether it's possible to share a rotary rake among different farms or cooperatives is another supplementary query to consider.

Q & A

Q1: What safety features does a modern rotary rake have?

A1: New-generation rotary rakes have safety features like slip-clutch protection and fold locks. They also have a speed limiting mechanism to avoid accidents from excessive speed.

Q2: How does a rotary rake compare with a rotary tedders

A2: A rake is used to gather windrowed hay into bundles for easy picking or baling, while a tedder is used to further spread tedded hay for faster drying. Also, a rake works by turning the hay from the ground while a tedder scatters the hay using rotating forks. Generally, a teder prepares hay for drying while a rake prepares it for storage.

Q3: What does the capacity of a tractor rake mean?

A3: The capacity refers to the amount of hay the rake can handle at a go, usually expressed in pounds. This determines the number of hours the rake will work to get a given amount of hay raked.

Q4: How long does it take to rake hay with a rotary rake?

A4: The time taken to rake hay depends on several factors; the number of hours the pasture field normally takes to dry, the size of the field, the width of the raked swaths, and the speed at which the rake is operated. With these factors in mind, it can take up to 2 hours to rake a field of half a hectare using a standard rotary hay rake.

Q5: What are the main benefits of investing in a tractor rotary hay rake?

A5: A rotary rake saves time and labor costs. It produces neat raked piles of hay that are easier to collect during harvesting. Some models offer automation features that smoothly integrate into modern farm management systems.