(11207 products available)

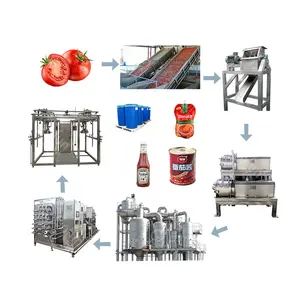

The tomato sauce making machinery is a key device used to produce tomato sauce and paste. There are many devices in the production line that are used to produce tomato sauce efficiently. These devices allow producers to make different types of tomato products based on the preferences of their customers.

Here are the common types of tomato sauce-making machines:

Tomato Sorting Machine

The tomato sorting machine is used after harvesting. It is used to sort the tomatoes based on their sizes and weights. This machinery also removes the undesirable tomatoes that have rot or bad quality. Due to its ability to sort tomatoes based on size and weight, this machine ensures a uniform final product.

Tomato Washing Machine

The washing machine cleans the tomatoes after sorting. It uses water to remove impurities, mud, and pesticides from the surface of the tomatoes. The tomato washing machine prepares the fruits for further processing, ensuring high-quality tomato sauce.

Tomato Cutting Machine

Typically made of stainless steel material, the tomato cutting machine has a variety of blades and configurations. The tomato fruits are cut into slices or dices using this machine. The tomato cutting machine reduces processing time and ensures uniformity.

Tomato Crushing Machine

This type of machine mashes the tomato pieces into a pulp. Some tomato crushing machines separate skins and seeds from the pulp. It uses blades and sieves to ensure a smooth consistency for the sauce production.

Evaporator Machine

The tomato paste production line uses the evaporator machine to remove excess water from the tomato pulp. This concentration process results in a rich and thick consistency, which is ideal for making tomato paste and sauce.

Tomato Sauce Making Machine

After all the above processes, the tomato sauce making machine is the final step in the production of tomato sauce. The tomato sauce making machine usually has a frying pan and a mixing machine for even frying and mixing. Heat is used in the sauce-making machine to cook the concentrated tomato pulp with other ingredients (optional) to produce the final tomato sauce.

Filling Machine

The sauce is filled into bottles or jars using this machine. It uses storage tanks to hold the sauce and Automatic systems to dispense the sauce into containers safely and efficiently. The machine may have manual or automatic controls, as well as various size and shape containers.

Labeling Machine

Once the containers are filled, the labeling machine places the label on the container, which helps identify the product and provide information about the product ingredients.

The following are the main specifications related to tomato sauce machinery :

Production Capacity:

This refers to the amount of tomato sauce that the machine can process within a specific time. It can be expressed in liters or gallons per hour. For example, some industrial-scale tomato sauce machines may have a production capacity of 500 to 1000 kilograms per hour.

Power Consumption:

This refers to the overall electrical power usage of the tomato sauce-making machine. The amount of power used by the machine during the manufacturing process must be considered in order to determine its efficiency and energy usage.

For example, a tomato sauce machine with a 10-horsepower motor may consume 7.5 kilowatts of power when processing tomatoes.

Machine Size and Weight:

This refers to the overall dimensions and weight of the machine. For reference, an industrial tomato sauce machine may have a length, width, and height of 5,000 millimeters, 2,500 millimeters, and 3,000 millimeters respectively, and its weight may come to around 5 tons.

Machine Material:

Generally speaking, tomato sauce machines are usually made of stainless steel or other corrosion-resistant materials in order to ensure their durability and hygiene. This helps to satisfy the requirements of food safety and hygienic standards.

Automation and Control:

Some machines provide automatic functions and control systems to streamline the manufacturing process. An example is a machine equipped with programmable controls that allow operators to preset tomato sauce-making recipes and parameters, thereby ensuring consistent quality and taste.

It is necessary to ensure that the tomato sauce machine is produced continuously over a long period of time. Therefore, proper maintenance is vital in order to ensure that the machine operates normally and reliably, so as to achieve stable production and continue to meet demands.

In conclusion, the maintenance of the tomato sauce-making machine is quite essential, and it can increase its life span and also, enable it to operate well for a long time. Frequent maintenance and inspection will make it become a useful work tool for business owners in the manufacturing process.

Regular Cleaning:

It is necessary to clean the tomato sauce-making machine on a regular basis, so as to prevent the remains of tomatoes or seasonings from affecting the flavor of the sauce. In addition, the bacteria that may be breeding in the machine after the production process should be gotten rid of.

Lubrication:

It is necessary to apply lubricant to movable parts of the tomato sauce-making machine on a regular basis, including bearings, chains, etc. This will ensure that the machine works steadily and smoothly and will lessen any mechanical wear and tear.

Regular Parts Inspection:

The key parts of the tomato sauce-making machine, such as motors, pumps, presses, etc., are to be regularly inspected to ensure that their connections are secure, and that there are no signs of damage or leaks. Any problems discovered should be addressed immediately so as to avoid causing unnecessary downtime and loss.

Production line tomato sauce machines are used in the industrial food-making sector, including factory food production, restaurant food production, and other food-production industries that require tomato sauce as a fundamental ingredient in the foods that are produced. Usually, tomato sauce production line machines are part of a greater food-machine production line that helps to efficiently and rapidly produce food items at a consistent and high quality.

Tomato sauce-making machines can also be used at food-processing tomato sauce hubs to create tomato sauce in large quantities. These may be distributed through wholesale channels or other food-processing tomato sauce hubs.

Aside from this, tomato sauce machines can be used to make tomato sauce to create canned tomato sauce, tomato sauce pouches, bottles of tomato sauce, or tomato sauce sachets for retail.

Some food-production industries that require tomato sauce include the ketchup industry, pizza sauce production industry, pasta sauce production industry, and salsa industry, to name a few. All these industries use tomato sauce machines tailored to their specific needs and the unique qualities of sauces they want to manufacture.

Imported tomatoes are processed into tomato sauce. Therefore, custom tomato sauce-making machines can be used at customs clearance warehouses, such as border tomato sauce processing facilities, where tomatoes are imported and must be processed quickly to make them fit for consumption in the local country.

Research and Development tomato sauce machines are used in to create new varieties of tomato sauces with different flavors and textures. These experimental machines are typically used in lab settings or R/d teams within larger food production companies.

Restaurants may use tomato sauce-making machines to create unique sauces and flavors that set their dishes apart from those of their competitors. This helps the restaurant achieve a certain branding that their customers have learned to know and love. These are usually smaller machines that are easy to handle and have a low capacity for production.

Considering certain factors can help business owners make the right choice of commercial tomato sauce making machine.

Production capacity

Business owners should determine the machine's capacity based on their production needs. They should consider factors like the volume of tomatoes processed per batch, the machine's processing speed, and the overall efficiency to ensure it aligns with their desired production levels.

Automation and control

When choosing tomato paste processing machinery with automation, business owners should look for advanced control systems that provide precise monitoring and adjustment of processing parameters. These may include temperature control, pressure regulation, time settings, and other relevant controls to ensure consistent and high-quality tomato sauce production.

Quality and safety standards

Business owners' priority should be to choose tomato sauce making machines complying with quality and safety standards. Such machines have certifications that meet industry-wide regulations. Sourcing machines from reputable manufacturers and suppliers is crucial to ensure they meet the required quality and safety standards.

Cleaning and maintenance

When selecting a tomato sauce-making machine, business owners should prioritize models that are easy to clean and maintain. Furthermore, they should choose machines with readily available replacement parts to facilitate maintenance and minimize downtime.

Q1: What are the benefits of commercial tomato sauce making machines?

A1: Commercial tomato sauce-making machines increase production by handling large volumes efficiently. They ensure consistent quality through precise control and reduce labor costs by automating processes. These machines also improve product yield, maximize extraction, and enhance overall operational efficiency.

Q2: How do commercial tomato sauce-making machines improve product yield?

A2: Commercial tomato sauce-making machines enhance product yield by efficiently extracting juice and pulp from tomatoes, leaving minimal residue. They incorporate separation mechanisms that extract a higher percentage of usable material. Additionally, some machines offer adjustable settings, allowing operators to optimize the extraction process for maximum yield.

Q3: Can commercial tomato sauce-making machines handle different tomato varieties?

A3: Yes, commercial tomato sauce-making machines are designed to handle various tomato types, such as roma tomatoes for tomato sauce or cherry tomatoes for tomato ketchup. These machines adjust processing parameters like temperature and duration to suit each variety's texture and flavor, ensuring optimal results.

Q4: What is the typical capacity of commercial tomato sauce-making machines?

A4: The capacity of commercial tomato sauce-making machines varies depending on the model and specifications. Some machines can process up to 500 kilograms of tomatoes per hour, while larger industrial-scale machines can handle higher volumes, reaching capacities of 1,000 kilograms per hour or more.