(570 products available)

With the development of industry, many types of table shot blast machines have been created to meet the requirements of different industries and different levels. Nowadays, people can find a large variety of table shot blast machines from web pages such as Cooig.com. Here are some of the most popular ones.

Automatic table shot peening machine

An automatic table shot peening machine is a device used to carry out the shot peening process automatically. Shot peening itself is a process used to enhance the mechanical properties of materials, especially metals. It involves the controlled introduction of spherical shot (usually made of steel, glass, or ceramic) to impact the surface of the material being treated. This impact creates small indentations on the surface, leading to surface and near-surface compressive residual stress, which can improve fatigue life, resistance to stress corrosion, and other beneficial properties. The automatic table shot peening machine uses automation to streamline the shot peening process, ensuring consistent coverage and treatment of the material's surface.

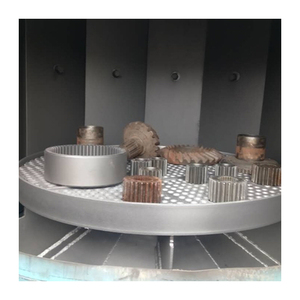

Automatic indexing turntable shot blast machine

An automatic indexing turntable shot blast machine is a specialized equipment used in the shot blasting industry for surface cleaning, descaling, and strengthening of metal parts. This machine utilizes a turntable that indexes or rotates at certain intervals to expose different parts of the workpiece to the shot blast stream. The shot blast stream, made up of small spherical particles, is propelled towards the workpiece using high-speed turbines or air propulsion. The impact of the shot blast stream removes surface contaminants, rust, scale, welding slag, sand, and other imperfections, while also improving the surface finish and increasing the adhesion of coatings or clays.

Double table shot blast machine

A double table shot blast machine is a type of shot blasting equipment used for surface preparation of metal workpieces. In this machine, two tables (or work platforms) are provided to allow for continuous operation while one table is loaded and the other is in the blasting phase. The concept of a double table shot blast machine improves productivity by eliminating downtime associated with table swapping in single-table machines. While one table is subjected to the shot blasting process to clean and prepare the surfaces of the workpieces, the other table can be loaded with new workpieces. Typically, the shot material is propelled at high velocity onto the surfaces and edges of the workpieces by rotating discs, clearing away rust, scale, sand, and other surface impurities. After the blasting process is finished, the workpieces are exported for further processing or treatment.

Intelligent electro hydraulic table shot blast machine

Intelligent electro-hydraulic table shot blast machines are advanced surface treatment devices. The machine utilizes shot peening technology to enhance the fatigue resistance and durability of components, thereby prolonging their service life. This specific table shot blast machine is operated and controlled through an intelligent electro-hydraulic system. The electro-hydraulic system combines electrical and hydraulic control, enabling automatic and precise control over blasting time, frequency, intensity, and other parameters. With the intelligent control function, the machine can realize automated operation and decentralized control, and its blasting effect can be optimized by adjusting blasting parameters to meet different technological requirements.

The table shot blast machine's specifications differ depending on the model and manufacturer. The following are the common specifications for a table shot blast machine.

Like any industrial machine, the blast table machine requires some maintenance for consistent performance, desired results, and a longer lifespan. The following are some machine maintenance tips.

Danat shot blast machines are used in many industries that need to maintain or prepare surfaces. Only a few industries in which table shot blast machines are commonly used are described below.

Automotive

In the automobile industry, table shot blast machines are used for deburring/cleaning the after machining of parts (such as engine blocks, crankshafts, etc.), glass beading, rust removal from the chassis, wheel rims, etc., and paint stripping from plastic parts.

Aerospace

Components and parts of spacecraft and aircraft are abrasive blasted using blast machines to create a better surface for Adhesion of coatings and better surface performance for components.

Marine

Cleaning and removing corrosion from metal substrates (such as steel, aluminum, etc.) for coatings adhesion is what marine industries do every day, and they use table shot blast machines to do it.

Casting and foundry

Foundries and casting companies use specific table shot blast machines to create a smoother finish on casted parts. It is also used for removing oxide scales, sand residues, and imperfections from the surfaces of castings.

Forging

In the forging industry, the use of shot blast machines helps to remove scale, oxides, and surface imperfections from forged parts, improving surface roughness, adhesion of subsequent coatings or treatments, and preparation for machining.

Fabrication

Metal fabrication companies use blast machines to clean, deburr, and prepare surfaces of metal sheets and plates, angles, channels, and structural components for welding, painting, or further processing.

Medical

Shot blast machines are used in the medical industry for surface preparation and micro-abrasion of medical devices, implants, and surgical instruments to enhance adhesion, biocompatibility, and the performance of medical components.

Selecting the right table shot blast machine is crucial for achieving desired surface finishing results. Several key factors should be considered when making this equipment purchasing decision.

Types of parts to process

Consider the geometries of the parts, their sizes, weight, and the material from which they are made. Determine if the parts have complex shapes with deep holes or internal/external contours. Establish if the parts are small and light enough to fit on tables of blast machines. Confirm that the parts are compatible with the blasting media. If the item includes delicate components or assemblies that could be damaged by blasting media's impact, it may need masking or protection to avert damage.

Production rate requirements

Consider how many pieces need to be processed per hour or day. For high-volume production lines, select a machine with efficient handling systems like automated feeders, rotary tables, and rejected parts systems. For lower volumes or job shops, this machine may have manual loading and unloading.

Surface finish requirements

Consider what kind of surface finish is needed. The intensity of the surface finish depends on the machine selected, the type and size of blasting media used, and the processing time. Whether this requires removing rust, scale, paints, or other contaminants or peening to enhance fatigue strength must be considered.

Maching availability and trouble repair

Buying from a supplier with local service and support will assure buyers the needed parts and repair services whenever required. Suppliers who provide extensive warranties cover repairs and replacement parts under their warranty.

Budget constraints

Consider the price of this machine, including system options. Focus on the essential features for the application and evaluate the cost vs. performance of possible machines.

Q1: Which materials can benefit from table shot blasting?

A1: The table shot blast machine is used mainly on metal materials such as iron, steel, aluminum, copper, alloy, etc. However, the machine can still be used on other materials such as plastics and ceramics as long as the material is not too brittle to take the impact of the blasting shots.

Q2: Can a table shot blast machinemaintain the strength of the blasted material?

A2: Yes. This is one major advantage of using the shot blast machine as a surface finishing tool. It has the potential to clean the surface of an object and improve its appearance while improving rather than decreasing the structural integrity of the blasted object.

Q3: How does a blaster operator know when it is time to replace the blasting media?

A3: The blasting media can be replaced after several cycles of blasting based on the task at hand. It can also be replaced when it is damaged beyond recovery or too degraded to achieve the desired level of blasting. The operator should also consider the level of contamination in the blasing media and its effect on the object being blasted. If there is too much clean-up expense following the use of the blasting media, it is better to replace it to save costs.

Q4: How does the shot blast improve the durability of metal surfaces?

A4: The shot blast improves the durability of metal surfaces by removing surface impurities, enhancing metal surface adhesion, and producing a protective oxide layer. Ultimately, all these factors contribute to improved coating adhesion, better bonding of metal surfaces, and increased resistance to corrosion. Therefore, following the shot blast machine treatment, the table blast machine can improve the lifespan of the metal object in question.