(413 products available)

Sulzer weaving machines are popular in the textile industry because of their efficiency and high productivity. Like all machines, the Sulzer looms wear out and need some spare parts. This creates an opportunity for business buyers looking for Sulzer loom spares to invest in a profitable market.

The parts listed below are typically in high demand.

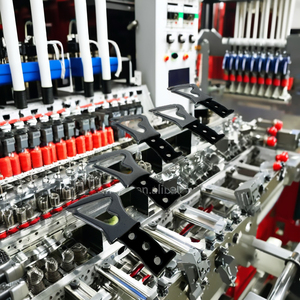

Besides these, other Sulzer loom spares are the electronic and control parts. These include sensors (tension, selvedge, fabric quality), looms control computers, programmable logic controllers (PLCs), and monitoring systems. With the textile industry moving towards greater automation, the South electronic spare parts are likely to be in greater demand.

Also, the common wear and tear parts like belts, bearings, pulleys, drives, and couplings must also be repaired or replaced on the regular basis. These are also the Sulzer loom spares that sell fast.

Assess market demand by talking to existing customers and their end users. Understanding the market demand will help identify the type of spares supply to order.

Flexible strips:

They have a standard length of 1050 mm-2200 mm, adjustable according to customized needs. They are made with strong materials that can withstand growing demands. Their weight and thickness can also differ depending on the model.

Shuttles:

Shuttles can differ in sizes and weights, usually between 0.8kg and 2kg. They also have to fit the particular loom model. Materials used for shuttles' production can differ; they can be made of wood, aluminum, or other light materials.

Weaving yarn carriers:

The carriers' measurements also have to be compatible with the loom. They are often made of polymers or lightweight metals, and their weight usually varies from 0.5 kg to 1.5 kg.

Winders:

Depending on their type, winders can be electronic or mechanical and automatic or semi-automatic. The carrying capacity of a typical winder is around 3.5 kg, and the diameter is around 600 mm.

To make sure solzer loom spare parts last for a long period and work properly, regular maintenance is needed.

Some of the usage scenarios of the Sulzer loom spares are as follows:

Textile factories looking for Sulzer loom spare parts have to look for durable spares to ensure the machines can run for a long period without the frequent need for replacement. With the high weaving speed of the Sulzer weaving machines, it is vital for spare parts to be able to cope with the stress of continuous usage at high speeds.

Weaving machines are made of metal, and over time, due to friction and stress, some metal parts may wear and tear or break. Buyers should look for Sulzer loom spare parts made of high-quality metals. If any parts require a coating for additional protection, buyers should ensure the coating is applied correctly.

Routine maintenance is very important. It can minimize the need to purchase loom spare parts. Buyers should get maintenance tools like maintenance kits and lubrication so that the weaving machines are regularly oiled and looked after. An efficiently maintained weaving machine will run smoothly and not require frequent replacement of spare parts. Some useful repair tools included in maintenance kits are wrenches, hammers, screwdrivers, pliers, and shuttles.

Like all sophisticated machines, it is essential to have the right spare parts for the weaving machine. To find the correct Sulzer loom spare, buyers should determine the model number of the weaving machine so that they can find suitable spare parts. Further, buyers can compare the fit and functionality of the loom spare parts to ensure they are investing in the right items.

Because spares wear and tear over time, buyers may invest in wholesale purchases and look for suppliers who can give them bulk discounts. Regular Sulzer loom spares that are in high demand in the market can be kept in inventory and supplied to customers who are also looking for quality spare parts.

Q1: What is a loom and its uses?

A1: A loom is a machine for weaving fabric. Looms cycle threads lengthwise and crosswise to create different textiles by efficiently interlocking the threads together.

Q2: What are some types of looms?

A2: The Sulzer loom is among the most popular wide looms. Other common types of looms include Jacquard looms, Fly shuttle looms, Tapestry looms, Hand looms, and Air jet looms.

Q3: How have looms changed over time?

A3: Historically, weavers used to manually interlock threads with a simple device, the shuttle, and beat down the woven threads with a tool called the batten. Today, looms are complex pieces of machinery that can weave, not just fingers but entire spaces, very quickly.

Q4: Can a damaged Sulzer loom be repaired, instead of buying a new one?

A4: Some parts of a loom can be repaired or replaced, like the belts, blades, bearings, shafts, etc., with a Sulzer loom spare. However, if a machine is damaged significantly, especially its internal parts, it's usually best to replace it with a new one.