(541 products available)

Single-Side Straw Rakes

Single-side straw rakes are developed to function mainly on one side. The equipment utilizes the distinct trait of being constructed with its operational components installed on only one side of its frame. This makes it an ideal function for agricultural activities that need extra attention given to one side of the field or barn floor.

Advantages:

Single-side agriculture rakes are efficient in managing straw in large quantities in selected areas. These rakes are deemed fit for large-scale agriculture where they improve the effectiveness of practices in a targeted area.

Double-Side Straw Rakes

Both side straw rakes have working features on both sides and are suitable for the even spreading of straw across the farms and pastures. They are used for effective performance because of two operational sides, which means they can also pass as suitable for use in balanced performance on either side.

Advantages:

These rakes achieve uniform straw distribution across the fields, which can be useful when striving for even growth of crops. In addition, they are good for light practices since they work best on small straw levels.

V-Prime Straw Rakes

The V-Prime straw rakes have some of their tines set inward in a V-form subsidizing adequate collection and consolidation of straw. The general merit to this frame is that it has evolved to be efficient and effective in several farming practices while at the same time collecting and managing straw appropriately.

Advantages:

Because of its construction, the V-Prime straw rake can effectively gather straw into neat rows, which are thereafter easy to collect. It provides maximum functionality in practices with high amounts of straw.

Revolving Straw Rakes

As the name hints, revolving straw rakes use a rotation motion with the help of tines to spread and pull straw. Most of these rakes are employed behind tractors, and their tines rotate to achieve straw row formation or spreading.

Advantages:

The revolving action of these rakes allows them to operate effectively on a variety of terrains without disturbing the soil too much. This makes it possible to use them in many situations, including pasture maintenance and field clean-up of straw.

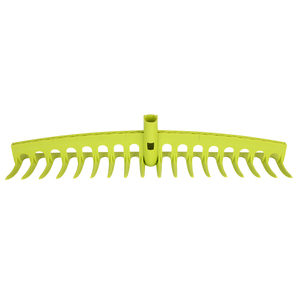

Landscape Rakes

Landscape rakes are intended to do more than just handle straw; they're meant to handle landscaping jobs such as leveling soil, spreading seeds, and clearing debris. They have adjustable tines that are suitable for various projects in landscaping.

Advantages:

Landscape rakes can be modified to function properly for a certain project, which would make them better as a multitasking tool in landscape and agricultural sectors.

Steel Alloys

Along with different metals, most straw rake tines are produced using high-tensile steel alloys. Advantageous element-wise, steel alloys can be used to supply the tines with toughness, strength, and elasticity to resist high pressure.

Durability Benefits:

High-strength steel alloys can withstand wear and break, making them less likely to be replaced frequently. This means less downtime during repairs and more productivity in the field.

Spring Steel

Various straw rake tines are produced with spring steel, a steel that highly supports elasticity and strength. A material such as this one can allow the tines to bend in case of an impact and return them to their normal position.

Durability Benefits:

The ability to bend and return reduces the risk of breaking tines during tough operations. This further enhances durability in rocky terrains or fields with dense residue.

Galvanized Coating

Some straw rakes are fitted with galvanized-coated tines and frames to prevent the materials from rusting and corroding, especially when rakes are used in wet conditions.

Durability Benefits:

Galvanization can extend the life of the rake by several years, permitting outdoor operations without fear of deterioration. This saves much money on investments in equipment over time.

High-Strength Steel for Frames

The main components of straw rakes or frames are usually made of high-strength steel. These frames are strong and can bear the heaviest loads without bending or breaking.

Durability Benefits:

Frames made of high-strength steel alloys provide long-term support to resistance against friction and wear and, therefore, can be used even under extreme conditions.

Wear-Resistant Steel

Commonly, the tines of the straw rake are made of wear-resistant steel. The steel is a special type of metal that has hard compounds on the surface so that the surface is not easily damaged when exposed to abrasives.

Durability Benefits:

This type of steel will ensure that tines remain effective for a long time, even in applications where they are exposed to harsh elements such as soil, rocks, and debris.

Distributing Straw on Fields

A straw rake is used to manage straw after harvest and place it evenly on fields. This promotes proper moisture and nutrient absorption by the soil, which subsequently makes the straw beneficial to the soil as organic mulch.

How It Helps:

The even placement of straw means no heavy or bare patches, which can lead to problems: poor growth or disease. An even cover enhances crop production and health.

Cleaning Up Straw in Barns

Also, straw rakes are used to clean up straw left on the floors in livestock barns and facilities. The rakes make it possible to clear the straw so that the floors can be ready for the following bedding.

How It Helps:

Straw left to decompose can cause bad smell and lead to diseases if allowed to stay in the barn; hence, use of rakes to eliminate this problem transfers this straw away from the floor.

Pasture Management

Straw rakes can also be applied on pasture to spread manure thinly and evenly. This will ensure that nutrients are available in sufficient quantities to plants without overfertilizing certain areas.

How It Helps:

Even distribution of manure prevents overgrowth in some places and nutrients shortages in others, which makes the pasture greener and healthier. This makes use of pasture harrows to be integrated into nutrient management systems.

Preparing Seedbeds

Straw rakes are important implements that help in seedbed preparation for sowing. In this case, the rakes spread dust and remove debris from topsoil to put it in proper order for seed planting.

How It Helps:

A clean seedbed free of straw and debris provides better soil-to-seed contact, which aids in germination and crop establishment. This leads to more uniform and successful stands of plants.

Controlling Erosion

Straw rakes are useful when raking straw in hills with strong winds to cover the topsoil with straw so as to avoid soil erosion. Their main creation is to distribute straw in a crisscross manner so that it must cover the ground.

How It Helps:

Achieving such coverage helps the straw to hold the soil in place with the help of rainfall and winds, which transform ecological sustainability into reality and reduce soil erosion problems. This further helps in promoting better soil health and crop yield.

Type of Straw

Rakes that work well for one type of straw may not necessarily work well for another. Fine straw requires a fine bed with closely spaced tines to allow collection, while coarse straw requires wide spacing between tines so that the tines can go through the straw and rake it up.

For this reason, one must make sure that the rake selected is appropriate for the type of straw that is usually handled in the given agricultural business.

Rake Width

The width of the straw rake should be compatible with the tractor and the size of the operation in general. Larger width size rakes are carried out faster, but width should also be practical for usage in small and large fields.

A properly sized rake will do a better job and not cause harm to the tractor or the rake itself. This ensures maximum efficiency for all equipment used in farming.

Tine Material and Durability

Tines attached on the straw rake are to be made from strong materials such as wear-resistant steel or spring steel. These materials are durable and can sustain huge loads without bending or breaking.

Also, consider tines with galvanized or coated finishes; they provide further protection to rust and wear, especially when exposure to weather elements is common.

Adjustable Tines

One may wish to consider a rake with easily adjustable tines since the spacing and height of the tines can vary depending on the straw type or the ground condition.

Good tines ensure good contact between the tines and the straw and make sure that the tines properly handle the straw without disturbing the topsoil. Thus, this adjustment provides that the rake works well in various situations.

Ease of Storage and Transportation

There is also a need to consider whether the rake has a foldable design or a mechanism for easy storage and transport so that it can be easily moved from one location to another.

Collapsible features not only enhance convenience but also avoid potential dangers when operating in transit. This allows the rake to fit into smaller spaces when kept.

A1: Straw rakes are used to spread, level, and incorporate straw into the soil or prepare surfaces for landscaping purposes, pasture maintenance, or seedbed preparation, achieved through their adjustable tines.

A2: Straw rakes are employed after harvesting when straw covers the fields, during pasture maintenance to manage debris, before planting to prepare seedbeds, and while establishing landscaping projects requiring straw incorporation.

A3: While designed mainly for straw-related tasks, rakes can also handle light landscaping, soil leveling, and pasture maintenance, although specialized equipment may be preferred for more demanding or distinct chores.

A4: Straw rakes aid in efficiently managing straw residues, enhancing soil health by incorporating organic matter, promoting better drainage and seed germination through surface preparation, and maintaining healthy pastures and landscapes.

A5: Selecting a suitable rake involves considering the straw type and field size, ensuring compatibility with the tractor's horsepower, and choosing between a fixed or adjustable rake, depending on the specific task requirements.