(6346 products available)

A stick counting machine, also known as a tally counter, comes in various types, each designed to meet specific counting needs.

Button-Based Counters

Button-based stick counting machines are the most common types available. They are usually small handheld devices with a single button on the counter's surface. Users manually push the button to count. Each button push represents a count increment. These machines may have LCD screens that display counts. Some may even have the ability to reset counts via a designated button.

Automatic Stick Counting Machines

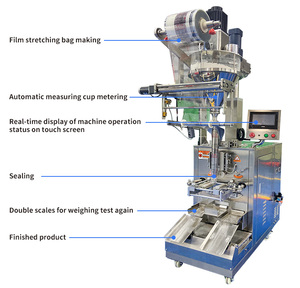

Automatic stick counting machines are devices that can count items automatically without the need for manual intervention. They generally employ different methods to count items. Some stick counting machines use sensors that detect and count items as they go by. Sensor-based counters usually have a photo eye sensor that detects objects passing by. Some may use a laser sensor that detects objects through a laser beam. When an object breaks the beam, the laser sensor counts the object. Others may use weight sensors that detect changes in weight, then count the objects. For instance, when a factory conveyor belt transports boxes, an automatic weight stick counting machine can count them based on weight changes.

Another method automatic stick counting machines use is image recognition. Advanced automatic counting machines use cameras to capture images of objects. Image processing software then analyzes the images and counts the objects based on their shapes and patterns.

Some automatic counting machines can also count in different dimensions and shapes. They are often used in industrial settings.

Digital Counters

Digital stick counting machines have an electronic display that shows counted items. Their counts can be more significant and are easy to read. In most cases, digital counters provide a more accurate count than manual methods. Apart from the button-based design, other digital counters have various functionalities applicable to different situations.

Mechanical Counters

Mechanical stick counting machines are counters that manually register every counted item by flipping a small dial on the device. Every flip of the dial indicates one count. These machines work without batteries or electricity. Their main advantage is simplicity and sturdiness. However, mechanical counting machines are gradually being replaced by digital counting machines because they are imprecise and difficult to obtain exact counts.

Input volume

It is the maximum quantity of sticks the machine can take in for counting in one batch. This capacity affects the counting speed and efficiency. Businesses with high stick production should have a stick counting device that can handle a large input volume. During use, one should avoid overstuffing the machine to ensure accuracy and prevent jams.

Counting speed

It indicates how quickly the machine counts sticks per minute. It may vary based upon the type of machine, stick size, and complexity. For efficiency, set the optimal counting speed based on the stick's size and the machine's capability. Regularly monitor the counting speed to maintain an ideal balance.

Accuracy

The machine's ability to count sticks correctly influences quality control. When working with a stick counting machine, users should prioritize models with a high level of accuracy. This ensures precise counting and minimizes errors. Regularly calibrate the machine to maintain its counting precision.

Automation features

These may include digital displays, touch-screen controls, and automated categorization. They enhance user experience and counting efficiency. Users should take advantage of the automation features for a more straightforward, convenient, and effective counting process. Properly train operators on how to use and understand these features for maximum benefit.

Durability and build quality

The materials and construction of the stick counting machines affect their lifespan and ability to withstand frequent use. Go for machines with high build quality and robust materials. They can endure regular stick counting demands for a prolonged period. Regularly inspect and maintain the durability components to enhance their lifespan.

Due to heavy usage, it is just natural that, over time, the stick counter machine will need repairs. Here are a few maintenance tips to always keep the machine in a better running state:

Regular cleaning

Regular cleaning of the stick counter helps eliminate dirt, debris, and dust that impact its performance. So, frequently wipe the surfaces and components of the machine using a soft cloth and mild cleaning solution. This prevents the build-up of materials that can cause counting inaccuracies and malfunctions.

Calibration

Regularly calibrate the stick counter to maintain its accuracy and ensure it counts sticks correctly. During calibration, adjust the settings based on the stick's size and verify that the machine operates as it should. Properly follow the manufacturer's prescribed calibration procedures and schedule to maintain the counting precision.

Software updates

Install any available software updates for the stick counting machine. The updates improve the machine's performance, enhance its counting efficiency, and add new features. Follow the manufacturer's instructions carefully when installing the updates. This ensures the stick counter is operating with the latest software enhancements.

Regular inspection

Frequently inspect the stick counting machine. Check its components for signs of wear, damage, or loose parts. By regularly examining the counter machine, users will detect potential problems early enough. They can then take immediate action to prevent them from getting severe and affecting the counting process.

Typically used in the forest industry, the stick counting machines have also found various applications in other industries.

When choosing a stick counting machine, consider the required application in various industries. Different sectors have unique needs when it comes to counting stick items. For instance, industrial manufacturing may require a counter that can handle high-volume output with strict accuracy. On the other hand, a simple wooden stick counting machine may suffice for retail.

Also, consider the integration of the counting device with existing systems. Some businesses have automated production lines and inventory systems, so they need counters that can seamlessly connect to what they already have in place. Meanwhile, startups may not need to worry about integration as they don't have advanced technologies yet.

Operating speed is also an essential factor to consider when purchasing a stick item counter. Machines that count sticks quickly are ideal for high-production industries where large volumes need to be processed within short periods. However, slower models may be more affordable options for small-scale businesses or those that handle less quantity but still require accuracy in their counts.

It's crucial to evaluate the size, shape, and material of items that will be counted by the stick counter machine. Some counters are designed specifically for certain types of materials, such as wooden sticks or plastic ones, while others can handle various shapes and sizes

Cost is another important consideration when buying a stick-counting device since budgets vary among different businesses. Industrial-grade machines tend to be more expensive due to their capability and efficiency compared to simpler models like manual counters which are affordable for small-scale use. It's essential to do research on prices before making a decision so that it aligns with budget constraints.

Q1: How durable is the stick counting machine?

A1: The durability of the stick counting machine will depend on the materials and craftsmanship used in its manufacturing. Countings sticks are often made of high-quality plastic or composite material to ensure good impact resistance, moisture resistance, and high temperature resistance. With proper care and maintenance, it can be used for many years.

Q2: Can the stick counting machine be customized?

A2: Some manufacturers can offer custom choices. For instance, the color can be changed to fit a particular brand image or customer preference. Also, they can adjust the size to meet specific requirements or applications to ensure performance and usability. Moreover, businesses can also request modifications to features and functionalities to meet specific business needs.

Q3: What are the main advantages of the automatic stick counting machine?

A3: The automatic stick counting machine has many advantages. It can improve counting accuracy and ensure data integrity. Also, it can greatly improve work efficiency. This machine also has extensive application prospects. It can be used in various industries such as food, pharmacy, toys, and more.

Q4: How does a stick counting machine work?

A4: The stick counting machine works by placing items on the conveyor belt. Then, it will pass through the sensors and counting device. Finally, the counted data will be displayed on the screen.