(2658 products available)

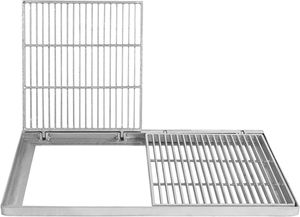

A stepped grate is a type of metal grid with a unique design used in various applications, such as industrial settings, construction sites, and outdoor spaces. This stepped grate has different heights or levels, making it easy to walk on and see through. There are several types of stepped grates, including the following:

Stainless steel stepped grate:

The stainless steel stepped grate is popular because it doesn't rust and is strong. It is used in places like homes, parks, malls, and offices where the stepped grate is exposed to weather elements and pedestrians. The stainless steel stepped grate comes in different sizes and levels to fit various spaces and meet different needs. It is easy to keep clean and has a modern look.

Aluminum stepped grate:

The aluminum stepped grate is lightweight and doesn't rust. It is mainly used in places with low traffic. The aluminum stepped grate is made from aluminum and has an open design, allowing water to flow through and preventing it from collecting on top. This type of stepped grate is usually used in residential applications like patios, decks, and driveways. It is easy to install and available in different sizes and shapes to suit various spaces.

Fiberglass stepped grate:

This type of stepped grate is made from strong plastic mixed with tiny glass pieces. It doesn't rust, is lightweight, and comes in many colors and sizes. The fiberglass stepped grate is mainly used in industrial settings like factories and power plants. It is resistant to chemicals and can handle harsh weather conditions.

Heavy-duty steel stepped grate:

The heavy-duty steel stepped grate is made from strong carbon steel that can support a lot of weight. It is mainly used in places with high traffic, like warehouses, industrial facilities, and factories. This type of stepped grate has a long lifespan and is affordable. However, it rusts easily and requires regular maintenance.

Painted or galvanized steel stepped grate:

Galvanized steel stepped grates have a coating that protects them from rusting. They are suitable for outdoor use and can last for many years without rusting. The painted steel stepped grate is first galvanized to prevent rust, then painted to improve its appearance. It is used in both outdoor and indoor settings.

Stepped grates, also known as stepped catwalks or stepped grids, are load-bearing metalwork platforms. They feature a series of steps or tiers that allow access to different elevations. The following are features of stepped grates.

Multiple tiers

The stepped grate has several tiers or levels. They are arranged in a rising sequence. The levels have a uniform height and depth. The multiple tiers provide access to different elevations. They allow inspection and maintenance at various height levels.

Non-slip surface

The top and all other levels of the stepped grate have non-slip surfaces. They are often serrated or ribbed. The non-slip surfaces provide traction. They ensure the safety of people and workers. Non-slip surfaces are important, especially when the stepped grates are exposed to water or oil.

Load capacity

Stepped grates are designed to support substantial weights. They can support the weight of multiple workers and equipment. They are made from strong materials like aluminum and steel. Their design also incorporates structural reinforcement. This ensures durability and safety during use.

Drainage slots

Many stepped grates feature drainage slots. The slots are located on every tier. They allow water to flow freely. The drainage slots prevent the accumulation of water on the surface. They ensure the stepped grate remains safe. The slots also reduce the risk of corrosion.

Modular design

Stepped grates are designed in sections. Each section is called a module. The modules can be easily assembled into larger units. This makes it easy to customize the size of the stepped grate. The modular design also simplifies transportation and installation.

Materials

Stepped grates are made from different materials. Common materials include galvanized steel, aluminum, and cast iron. These materials are resistant to wear and tear. They are also resistant to harsh environmental conditions. The materials ensure the stepped grates are durable.

Adjustability

Some stepped grates are adjustable. They have telescoping legs. The legs allow the grates to adapt to different heights. They accommodate varying industrial requirements. The adjustable features ensure the stepped grates remain stable. They also ensure safety when used in different settings.

There are different application scenarios for a stepped grate. These include:

Stepped grates in incinerators

Stepped grates are essential components of waste-to-energy incinerators. They provide a multi-level platform for waste materials. The design allows for better air distribution and efficient burning of municipal waste. The stepped design ensures that different types of waste are burned at different rates. This leads to effective energy generation.

Metal forging forges

Forges that create metal parts through high heat may use a stepped grate. The grate holds the coals or hot embers. It allows air to circulate and produces consistent heat for metal forging.

Paper mills

Paper mills use stepped grates in their recovery boilers. These boilers process wood waste and produce energy. The stepped grate allows the wood waste to burn efficiently. The heat generated is then used to power the papermaking process. The design also enables the ash from the burned wood to be collected in a stepped manner. This ash is then processed further to create valuable products.

Power plants

Some biomass and waste-fired power plants use stepped grates. The grates allow the biomass or waste to burn efficiently to produce steam. The steam turns turbines to generate electricity. The stepped design ensures a steady burn and maximum energy extraction from the fuel.

Large-scale commercial and industrial boilers

Large boilers in factories and plants often use stepped grates. The grates allow solid fuels like coal or biomass to burn thoroughly. This produces hot air, which is used in various applications. The stepped design helps reduce emissions and improve the overall efficiency of the boiler.

Power generation from alternate waste materials

Some facilities convert non-recyclable waste into fuel through gasification or pyrolysis. Stepped grates are used in the power generation process from this fuel. The fuel is then burned to produce electricity. The stepped design ensures efficient burning and power generation.

The stepped grate can be used in a variety of settings, including commercial, industrial, and residential. When buying stepped grates for sale, business owners should consider these factors to ensure they are meeting the needs of their end customers.

Environment Where the Grate Will Be Used

The stepped grate must be suitable for the specific environment where it will be used. Different materials have different weather resistance levels. For example, aluminum grates can be used in areas with heavy rainfall, while galvanized steel grates offer better rust resistance. Stainless steel grates are suitable for coastal areas with high saltwater exposure.

Type of Traffic the Stepped Grate Will Experience

Another factor to consider is the type of traffic the grate will experience. Grates used in areas with high foot traffic should be constructed with durable materials. They should also have features like anti-slip surfaces. For example, fibreglass grating can be used in low to medium traffic areas. Steel or aluminum grates are suitable for high traffic areas.

Load Bearing Capacity

The load bearing capacity is the maximum weight the stepped grate can support. It should be determined before choosing a stepped grate. Grates with a higher load bearing capacity are suitable for industrial applications. Lower load bearing capacity grates are ideal for residential or commercial uses.

Aesthetics

Aesthetics is a crucial factor when the stepped grate is used in residential or commercial settings. It ensures the grate complements the architectural design of the surrounding area. Stepped grates come in different finishes and materials. These include galvanized steel, aluminum, and stainless steel. Each material has a unique appearance that can enhance the visual appeal of a space.

Ease of Installation and Maintenance

Ease of installation and maintenance should also be considered. Some materials require special tools during installation. Others need professional assistance. The maintenance requirements of the material should also be considered. For instance, aluminium grates are easy to maintain, while steel grates require frequent maintenance to prevent rust.

Q: What is a stepped grate?

A: Stepped grates are also known as stepped catwalks or stair-step grates. They are durable metal sheets with holes used in industrial settings for stepping on. They have an excellent slip-resistant surface, are lightweight, and allow airflow and light. The stepped grates are used as walkways, platforms, and staircases in factories, power plants, warehouses, and industrial buildings. They are ideal for stepping on because they can carry heavy loads and withstand harsh conditions.

Q: What materials are used to make a stepped grate?

A: Stepped grates are made of metals that can withstand harsh conditions and heavy loads. Common materials are aluminum, steel, and fiberglass. Aluminum is lightweight and doesn't rust; it's used in stepped grates for pedestrian walkways. Steel is strong, durable, and rust-resistant; it's used in industrial stepped grates. They will last longer and are more expensive than steel. Fiberglass stepped grates are lightweight, non-conductive, and resistant to chemicals; they are used in specific industrial applications.

Q: How are stepped grates maintained?

A: Stepped grates are easy to maintain. They have durable materials that are easy to clean and resist wear and tear. The grates can be washed with soap and water to remove dirt, or they can be pressure washed. Metals rust, but they can be prevented by washing off water and not allowing it to pool on the grate. Stepped grates are not affected by UV rays, but over time, fiberglass grates will lose color and become brittle. Regular inspection and replacement of damaged grates maintain the structural integrity of the stepped grate.

Q: How is the load capacity of a stepped grate determined?

A: The load capacity of a stepped grate is determined by the material, thickness, and spacing of the bars. The load capacity is calculated using deflection theory, which considers the support configuration and load distribution. The grate's span and support system also affect load capacity; the longer the span, the more deflection will occur. Manufacturers determine the load capacity, and they use engineering principles to design steel grates that meet safety standards.