(31234 products available)

There are three main types of stainless steel gratings listed below:

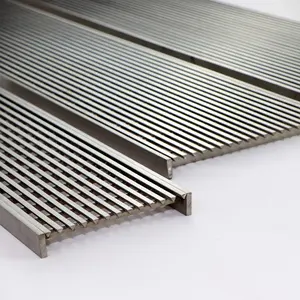

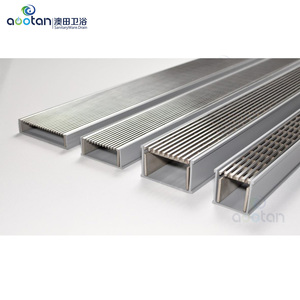

Bar Grating

Bar stainless gratings are made of long steel bars. They are set close together. This makes a strong and see-through surface. Bar grates are used on floors and decks. They let light and air through while staying very sturdy. Bar grates come in two main types. Heavy-duty grates use thicker bars. They are extra tough for places with high traffic or weight demands. Standard-duty grates have thinner bars. They are suitable for areas that do not need as much strength.

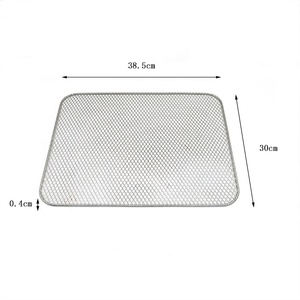

Expanded Metal Grating

Expanded metal grating is made from one piece of metal that is stretched and formed into a pattern. This makes it very durable yet lightweight. Expanded metal grates are slip-resistant. They allow air and light to pass through. This style of grating works for many different uses. It is suitable for industrial floors, platforms, and walkways. Openings are kept small enough to meet health rules. Expanded metal grates come in three material options. Aluminum expanded metal grates are corrosion-resistant and lightweight. Stainless steel expanded metal gratings look sleek and last a long time. Carbon steel expanded metal gratings are very affordable.

Perforated Metal Grating

Perforated metal grating has many small holes punched into it. The holes make the grating lighter while still being strong. The pattern of the openings gives the grating style and slip resistance. Perforated metal grates come in different styles. They can have round, square, or triangle-shaped holes. The holes can also be lined up in a staggered or straight pattern. Staggered holes provide better slip resistance.

Stainless steel gratings are essential components used in various industrial and architectural applications. They offer numerous beneficial features due to their unique properties. Here are the functions and key features of stainless gratings:

When choosing the ideal stainless steel grating for a particular application, it is essential to consider various factors to ensure optimal performance, safety, and longevity. Here are some critical factors to consider when purchasing stainless gratings for sale:

Application Requirements

The application environment significantly impacts the type of stainless steel grating to choose. For marine environments, choose a type with excellent corrosion resistance, such as 316L stainless steel. 304 stainless steel grating is suitable for less corrosive environments. For high-load applications, consider a grating type with a high-strength load-bearing capacity, such as a cross-pattern or serrated grating.

Safety Standards

Check the local safety regulations and industry standards relevant to the intended use. This could apply to building codes, occupational safety requirements, and environmental regulations. Ensure the chosen type complies with all applicable standards to promote safety and avoid legal issues.

Slip Resistance

For gratings used in high-traffic or wet areas, ensure they have slip-resistant features. This could include serrated surfaces, bevelled edges, or anti-slip coatings. These features help reduce the risk of accidents and falls, promoting a safe environment.

Load Bearing Capacity

Consider the anticipated load or traffic volume passing over the grating. Heavier loads require a more robust design, such as a thicker bar or a closer spacing. Consult a structural engineer or a grating manufacturer to determine the optimal load-bearing capacity.

Ease of Maintenance

Choose a type that is easy to clean and maintain. Smooth surfaces without intricate patterns are generally more accessible to sweep and wash. Consider the long-term maintenance needs and costs associated with each grating type.

Aesthetic Considerations

When the grating is visible in finished spaces, consider its appearance. Opt for a style with a pleasing design and finish that complements the overall aesthetic. Options like powder-coated or galvanized finishes may enhance visual appeal and functionality.

Customization Options

Many grating manufacturers offer customization options. This includes varying bar sizes, spacings, and surface textures. Provide the necessary details and specifications required to meet unique functional and aesthetic needs.

Environmental Impact

Consider the environmental impact of the chosen grating type. This includes its life cycle, from production to disposal. Opt for a sustainable option that minimizes ecological damage, such as recyclable materials and energy-efficient manufacturing processes.

Q1: How durable are stainless steel gratings?

A1: Stainless steel gratings are very durable. They can last for many years. This is even more so in areas with a lot of foot traffic or industrial use. They are resistant to corrosion and wear out. They are also able to withstand harsh weather conditions.

Q2: What types of stainless steel are used for gratings?

A2: Various types of stainless steel can be used for gratings. These include 304 and 316 stainless steel. They offer different levels of corrosion resistance. Grade 316 stainless steel is the best option for areas that are very corrosive. Examples of such areas are coastal environments and industrial settings.

Q3: Are stainless steel gratings easy to clean and maintain?

A3: Yes, stainless steel gratings are very easy to clean and maintain. They have a smooth surface. This surface prevents dirt, debris, and contaminants from piling up. To clean them, simply wash them with water and soap. In high-traffic areas, power washing can be used to clean them. Additionally, they can be cleaned using a wire brush to remove any stuck-on debris.

Q4: Can stainless steel gratings be customized?

A4: Yes, stainless steel gratings can be customized. They can be made in different sizes, shapes, and designs. This is according to the specific needs of the customer. Some manufacturers offer different types of finishes. They also offer different types of load-bearing capabilities for gratings.

Q5: Are stainless steel gratings slip-resistant?