(3982 products available)

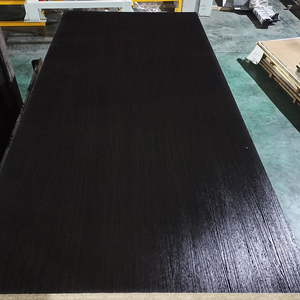

Solid fiberboard, also known as MDF board (Medium Density Fiberboard), is an engineered wood product made from wood fibers, wax, and resin, which are compressed under heat to form a dense board. Solid fiberboards are versatile and cost-effective, making them popular in home construction. It comes in different types and finishes depending on its application.

Medium-density fiberboard (MDF)

Medium-density fiberboard is a type of solid fiberboard made from wood fibers, wax, and resin. These materials are compressed under heat to form a dense board. MDF boards are cost-effective and versatile, making them popular in home construction. They are used in the construction of cabinets, furniture, and doors, and are also popular in the lining of walls and ceilings. Additionally, they are available in different grades and can be painted or veneered to suit specific needs.

High-density fiberboard:

This type of board is denser than the medium density board. It is manufactured using wood fibers, which are bonded using heat and pressure to form a solid, dense board. Solid fiberboards with high density are known for their durability and strength. They are used in applications that require superior impact resistance and structural integrity. These applications include load-bearing furniture, high-traffic cabinetry, and acoustic panels.

HMR MDF:

HMR MDF, or High Moisture Resistance MDF, is a type of solid fiberboard designed to withstand moisture and humidity. It is manufactured using a special resin that includes an anti-moisture agent. This makes it suitable for use in high-humidity areas such as kitchens and bathrooms. HMR MDF is commonly used in the construction of cabinets, wardrobes, and other furniture that requires exposure to moisture.

MR MDF:

MDF boards with Moisture Resistant (MR) are engineered wood products specifically developed for areas where moisture levels are not extremely high. They are manufactured with a specific resin formulation to provide basic protection against moisture. However, they are not suitable for use in high-humidity areas such as kitchens and bathrooms. They are usually used in the construction of built-in furniture like dressers and office furniture.

Fire Retardant MDF:

These are special types of solid fiberboards that are treated with fire-retardant chemicals during the manufacturing process. This treatment imparts fire-resistant properties to the board. They are used in applications where building codes require fire resistance, such as commercial properties and certain residential areas.

Flexible MDF:

These are specially manufactured boards that allow for easy bending and shaping. The fibers are arranged in a way that permits flexibility without breaking. They are used in applications that require curved or rounded surfaces, such as architectural moldings and custom designs.

Solid fiberboard has several features that make it suitable for a wide range of applications. These features include:

When choosing a solid fiberboard, consider the following factors to ensure the product meets the intended application requirements.

Moisture resistance

Solid fiberboard comes in different types, such as standard, moisture-resistant, and waterproof boards. Standard boards are suitable for dry areas, while moisture-resistant boards are ideal for areas with high humidity, such as kitchens and bathrooms. Waterproof fiberboard is suitable for outdoor applications.

Density and thickness

Fiberboard density and thickness affect its strength and stability. Higher density boards offer better load-bearing capacity and durability. Thicker boards provide better sound insulation and structural support. Choose a density and thickness suitable for the intended application.

Surface finish

Consider the surface finish of the solid fiberboard. Options include smooth, textured, or embossed finishes. Smooth finishes are suitable for painting, while textured finishes add aesthetic value. Choose a finish that complements the design requirements.

Environmental impact

Consider the environmental impact of the solid fiberboard. Opt for boards manufactured with sustainable practices, such as using recycled materials and low-emission adhesives. Look for certifications such as Forest Stewardship Council (FSC) to ensure responsible sourcing of raw materials.

Cost

While not the least important factor, the cost of the solid fiberboard should be considered in relation to the budget of the project. It is important to find a balance between affordability and quality to ensure that the chosen fiberboard is suitable for the intended use without going over budget.

Q: What are the types of solid fiberboard?

A: There are two main types of solid fiberboard, namely: high and low-density fiberboard. The low-density solid fiberboard is lightweight and commonly used in applications like backing panels and drawer bottoms. On the other hand, the high-density fiberboard is more durable and dense, offering superior structural integrity. It is also used in applications where moisture and pressure are likely to occur, such as in kitchen and bathroom cabinetry.

Q: What are the grades of solid fiberboard?

A: Solid fiberboards come in various grades, including insulation, sheathing, interior, exterior, and specialty grade. The insulation grade is primarily used for thermal insulation in walls, roofs, and floors, while the sheathing grade offers structural support and a base for exterior finishes. The interior grade is designed for visible surfaces, such as walls and ceilings, while the exterior grade is manufactured to withstand harsh weather conditions like moisture and rain. Specialty grades have unique features tailored for specific applications, like fire-resistant or moisture-resistant properties.

Q: What are the common applications of solid fiberboard?

A: Solid fiberboard is used in multiple applications. It provides a versatile and cost-effective solution in the automotive industry, office and home furniture, construction and building, packaging, and crafts and hobbies.

Q: What are the advantages and disadvantages of solid fiberboard?

A: The advantages of solid fiberboard include: it is cost-effective, it is smooth and easy to work on, and it is versatile. Its disadvantages are that it is less durable than solid wood, it is prone to moisture damage, and it is heavy.

The keyword "solid fiberboard" exhibits a steady web search volume trend with a notable peak, maintaining an average monthly web search volume of 10. Over the past year, there has been a significant increase of 100% in web search volume, with a similar rise observed over the last three months. The 12-month data reveals consistent interest with a few fluctuations.

Analyzing the monthly search data for "solid fiberboard," it's evident that the keyword experienced stable interest from December 2023 to August 2024, with the exception of August and November, where web searches doubled to 20. These peaks suggest seasonal variations or specific market events influencing search behavior during these months. The rest of the months show no change in web search volume, maintaining at 10 web searches per month.

The consistent web search volume throughout most of the year, coupled with the sudden peaks, indicates a pattern that might be influenced by external factors such as construction cycles, real estate market trends, or even regulatory changes affecting the use of solid fiberboard. However, without additional context, these fluctuations remain as observed trends in search behavior rather than attributed to specific causes.