Introduction to Silicon Carbide in Shanghai

Silicon carbide (SiC) is a high-performance material that is gaining popularity in various industries, especially in Shanghai, which is known for its advanced manufacturing and technological capabilities. Silicon carbide is a compound of silicon and carbon that exhibits exceptional hardness, thermal conductivity, and resistance to chemical corrosion. These properties make SiC an ideal choice for applications that require durability and robustness.

Types of Silicon Carbide Available in Shanghai

In Shanghai, silicon carbide is available in various forms, catering to different industrial needs. Here are the primary types:

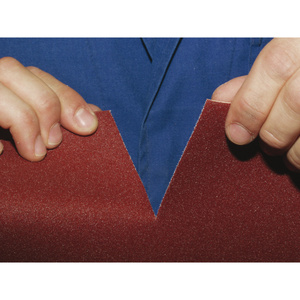

- Black Silicon Carbide: This is a widely used abrasive material known for its hardness and sharp edges, suitable for grinding and polishing applications.

- Green Silicon Carbide: Known for its high purity, this type is used for precision grinding, specifically of hard materials.

- Cubic Silicon Carbide: This form is used mainly in semiconductor applications due to its excellent electrical properties.

- Silicon Carbide Powder: This fine powder is used in various industries, including ceramics and metalworking, as well as in the manufacturing of abrasive tools.

Applications of Silicon Carbide in Various Industries

The diverse characteristics of silicon carbide have led to its adoption across numerous sectors in Shanghai, including:

- Aerospace: Used in high-temperature applications, such as turbine components, due to its heat resistance.

- Electronics: SiC plays a critical role in semiconductor devices, offering high efficiency and better thermal management.

- Abrasion and Cutting: Its hardness makes it an ideal choice for abrasive wheels, cutting tools, and grinding agents.

- Automotive: Silicon carbide components are utilized in electric vehicles for better performance and energy efficiency.

- Heat Exchangers: The material’s thermal conductivity and resistance to oxidation make it perfect for high-performance heat management solutions.

Advantages of Using Silicon Carbide in Shanghai

Choosing silicon carbide for your applications offers multiple advantages that set it apart from traditional materials:

- Exceptional Hardness: SiC ranks high on the Mohs scale, making it extremely resistant to wear and tear.

- High Thermal Conductivity: It effectively dissipates heat, which is crucial for high-performance applications.

- Corrosion Resistance: Silicon carbide is highly resistant to chemical attack, prolonging the life of components.

- Lightweight: SiC components are lighter than their metal counterparts, enhancing efficiency without sacrificing strength.

- Energy Efficiency: The use of silicon carbide can lead to lower energy consumption in various applications, helping companies meet sustainability goals.