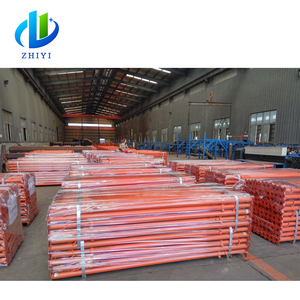

(2293 products available)

Shoring Jacks are used to stabilize and support a structure during construction or renovation. They are heavy-duty hydraulic jacks that come in different sizes, types, and designs to meet the requirements of the construction industry. Below are the types of shoring jacks:

Telescopic Shoring Jack: This shoring jack is popularly known for lifting and supporting beams and columns. It has a telescoping design that allows the jack to extend to different heights. The jack can be adjusted to fit different height requirements. It is commonly used in construction projects. The construction of this jack is made up of multiple sections that slide into each other, providing stability and support. It has a screw jack mechanism that allows lifting heavy loads with ease.

Acrow Jack: Acrow jacks are used for temporary support during the construction of walls, ceilings, and structures. It is designed to bear heavy loads and can be adjusted to different heights and widths. Acrow jacks are made up of steel, which makes them lightweight and easy to handle. It has a quick adjustment mechanism that allows for easy height and width adjustment. This jack provides excellent load distribution, which minimizes the risk of structural damage.

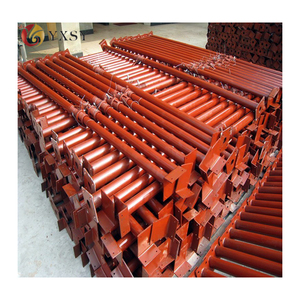

Strutting Jack: Strutting jacks support horizontal structures like beams and girders. These jacks provide a safe and secure temporary support system that ensures structural integrity. They are constructed with high-strength steel to withstand heavy loads. Strutting jacks have welded base plates and mounting brackets for enhanced stability and load distribution.

Ground Jack: These are heavy-duty hydraulic jacks used for shoring. They support and stabilize structures on the ground. They are ideal for new construction projects and can be adjusted to fit different ground heights. Ground jacks are constructed with high-strength steel for durability and stability. They have a heavy-duty base plate for stability on the ground.

Adjustable Jack Post: These jacks are developed to support vertical loads. They are used to support beams, columns, and other structural elements. Adjustable jack posts are made of high-strength steel, which makes them lightweight and easy to handle. They have a multi-piece construction that allows for height adjustment and fitting. Also, they come with a locking mechanism that ensures stability and security.

Load Bearing Capacity

Shoring jacks serve as supportive foundations for construction projects. Their primary purpose is to support loads temporarily. These include structural beams, walls, foundations, and other components until permanent support is installed. They assist in redistributing weight to the ground more evenly.

Adjustability

Shoring jacks are adjustable hydraulic jacks. They allow construction workers to modify their height to fit different project requirements. This ensures stability and security in varying construction site conditions. These jacks provide a customized solution for each project.

Material Strength

Shoring jacks are manufactured with high-strength steel. This provides durability and long-lasting use, even in harsh construction site environments. Their materials can withstand heavy loads and harsh weather conditions, making them reliable during usage.

Easy Installation

These jacks are very easy to install and put together. They come with a simple and detailed instruction guide that helps construction workers assemble them quickly. Shoring jacks are also easy to disassemble once the construction work is completed.

Stability and Safety

Shoring jacks offer a stable and secure solution for temporary load-bearing needs. They provide safety for construction workers and stability in building structures. These jacks have built-in safety features, such as locking mechanisms and pressure gauges, which ensure safe operations.

Versatility

Shoring jacks can be used in various construction applications. These include residential, commercial, and industrial projects. They are used in house lifting, underpinning, and supporting damaged walls or beams. Shoring jacks are also used to support formwork and scaffolding in concrete pouring and masonry work.

Corrosion Resistance

Most shoring jacks have a protective coating or treatment. This prevents them from being damaged by rust and increases their longevity. This allows them to work optimally in different weather conditions. For instance, galvanized coatings or powder coating is a popular example of shoring jack treatments.

Shoring jacks, also known as adjustable support jacks, are essential in providing temporary support during construction, maintenance, or renovation projects. Their applications span various scenarios where structural support is required. Here are some common applications:

Building Construction

Shoring jacks are commonly used in building construction projects. They provide temporary support to beams, lintels, and other structural elements during the installation process. This ensures a safe and stable construction environment.

Bridge Construction and Maintenance

These jacks are vital in bridge construction. They support bridge components such as girders and deck slabs until they are fully anchored and stabilized. They are also used in bridge maintenance to support structures while replacing critical components.

Renovation and Remodeling Projects

During renovation or remodeling of buildings, shoring jacks are used to support loads when removing load-bearing walls or structures. This allows for safe modifications to be made without compromising the structural integrity of the building.

Foundation Repair

Shoring jacks provide temporary support to a building or structure while the foundation is being repaired or reinforced. This ensures the safety of occupants and workers during foundation maintenance.

Underground Parking Garages

These support jacks are used to hold up the structure above while excavating and constructing underground parking garages. They ensure safe excavation and construction processes.

Utility and Pipeline Installation

Utility companies use shoring jacks to support structures such as trenches and pipelines during installation processes. This prevents collapses and ensures safe utility installations.

Heavy Equipment Support

In some scenarios, shoring jacks can be used to support heavy equipment or machinery temporarily, ensuring stability and safety when the equipment is not in use.

Shoring Jacks in Residential Construction

Shoring jacks are essential tools in residential construction projects. They provide temporary support to structural elements such as beams, floor joists, and rafters. This allows for safe construction and ensures structural integrity.

When buying shoring jacks in bulk, business owners should consider several factors to ensure they are getting jacks that will meet their customers' needs. Here are some of them:

Load Capacity

Shoring jacks are designed to support different loads. Therefore, it is important to determine the maximum load capacity required. The load capacity of a shoring jack should be considered before buying. Select jacks with a load capacity greater than the anticipated loads to ensure safety and prevent jack failure.

Construction Material

The material used to manufacture a shoring jack affects its durability and performance. Shoring jacks come with construction materials like galvanized steel or painted, which protects against corrosion. Choose shoring jacks made with quality steel or other durable materials.

Height Adjustment

Shoring jacks are used to support beams at different heights. It is important to select jacks that are height-adjustable to accommodate various project requirements. Consider the adjustable range to ensure they will reach the required height on site.

Stability and Base Plate

The stability of a shoring jack is very important because it affects its performance. Select jacks with a larger base plate to distribute the load over a bigger area. This will increase stability. Consider the base plate size and type, as it plays a major role in the stability of the jack.

Ease of Use

Shoring jacks are supposed to be easy to operate. When selecting a shoring jack, consider ease of use. Select jacks that are easy to operate and manipulate. Consider the adjustment mechanism, whether it's hydraulic, screw, or telescopic. The most important thing is to select a mechanism that is easy to operate and adjust.

Compatibility

Shoring jacks are used to support different construction materials like beams, walls, and slabs. It is important to consider the compatibility of the shoring jack with the materials that will be used in construction projects.

Safety Features

Shoring jacks should be equipped with safety features that ensure the safety of construction workers. Consider safety features like locking mechanisms, safety straps, and anti-slip coatings. These safety features will prevent accidents and injuries while on site.

Q1: What are the legal requirements for using shoring jacks in construction?

A1: Legal requirements vary by jurisdiction. Generally, construction companies must ensure their shoring jacks are tested and certified to support intended loads. They must also provide proper installation and use training to workers.

Q2: Can shoring jacks be used for long-term support?

A2: Telescopic jacks can be used for long-term support if engineered for that purpose. However, hydraulic jacks are ideal for long-term support since they provide stable, continuous support over extended periods.

Q3: How to maintain shoring jacks?

A3: Proper maintenance entails regular inspection, lubrication, and timely repairs. Inspect for signs of wear, corrosion, or damage. Lubricate moving parts to ensure smooth operation. Perform repairs as needed to extend their lifespan and maintain functionality.

Q4: How to choose the right shoring jack for a project?

A4: Determine the load capacity, height requirements, and project duration. Consider factors like soil conditions, climate, and budget. Consult with manufacturers or engineers to identify the most suitable jack type and model for specific project needs.

Q5: Are shoring jacks easy to operate?

A5: Yes, shoring jacks are generally easy to operate, provided the construction crew has received training. Telescopic jacks require manual adjustment, while hydraulic jacks operate using a pump to extend and lift the jack. Proper training ensures safe and efficient operations.