(112 products available)

Shoring jack weights, also known as adjustable jacks or shore jacks, are support devices with threaded steel rods and load-bearing flat bases used to support structures temporarily. These weights come in various types, including the following:

Acme Adjustable Weight

The Acme adjustable jack weight features a screw mechanism with a triangular-shaped screw called an Acme screw. This screw mechanism provides rapid adjustment with high load-bearing capacity. These weights are easy to adjust and are commonly used in construction projects.

Telescopic Jack

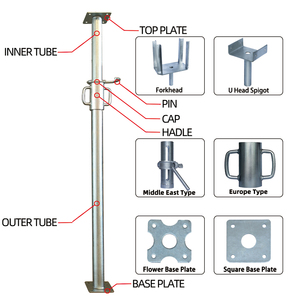

These weights have two or more sections that slide into each other for height adjustment. They are lightweight and easy to handle and are used as temporary supports for beams, slabs, and columns during construction.

Butt Welded Jack Weight

These weights are constructed by welding components together. They are used for shoring and are capable of carrying high loads. They are also easy to adjust and have a higher strength-to-weight ratio.

Stress Jack

Stress jacks are used to apply and measure prestressing tensile loads in concrete. They are designed for high-strength steel tendons and are adjustable to achieve desired stress levels. These weights are commonly used in post-tensioning and pre-tensioning applications.

Prop Jacks

Prop jacks are specifically designed for vertical support in construction. They have a load-bearing capacity of 10 tons or more. These weights are used to support beams, columns, and other structural components. They are easy to adjust and have high load-bearing capacity.

Form Jack

These weights are used to support concrete forms during pouring. They are made of galvanized steel to prevent corrosion and are lightweight for easy handling. They allow for precise height adjustments and are durable and stable.

Shore jack weights play an important role in construction projects. Their features also make them fundamental in construction support. Below are some features and their functions.

Adjustable Length

Shoring jack weights are designed with adjustable lengths. This allows them to be adapted to different project needs and site conditions. The adjustability feature also allows construction workers to customize the jack to fit different heights. This makes them useful in supporting different structures during construction.

High Load Capacity

Shoring jacks are designed to handle heavy loads. They provide necessary support to prevent collapsing. These jacks are constructed with strong materials and are reinforced. This ensures safety in construction sites. These jacks are reliable in shoring and underpinning projects. They support beams, walls, and other structures. This ensures they are stable and secure during construction.

Easy Operation

Shoring jack weights are easy to operate. They come with user-friendly controls. This enables precise adjustments and positioning. Some jacks are operated manually by hand cranks. Others have hydraulic or mechanical systems for easy and quick adjustments. This ensures the safety and efficiency of the operations.

Stability and Rigidity

Shoring jack weights are stable and rigid. This ensures the safety of the construction projects. Their stability and rigidity are as a result of their strong construction material. They are designed to resist buckling, bending, or collapsing under pressure. Their stability ensures that they provide consistent and reliable support.

Easy to Set Up and Dismantle

Shoring jack weights are easy to set up. They come with detailed setup instructions and diagrams. This enables a safe and efficient setup process. These jacks can be quickly adjusted and locked into position. This ensures that they are safely and securely fitted. Shore jacks can also be easily dismantled when the project is over. Their easy dismantling and assembly allow for repeated use in different construction projects.

Shoring jack weights are used in various construction and maintenance scenarios where temporary support is required. Here are some common usage scenarios:

Vertical Support

Shoring jack weights are used to provide vertical support to beams, columns, or walls during construction. They ensure stability and allow safe. Weight jacking is essential in lifting and supporting structures. These weights are also used to lift heavy objects to a desired height and weightlifting can be dangerous without proper support.

Horizontal Support

These weights can also be used to support horizontal members such as girders or lintels during installation. They help in evenly distributing loads and provide temporary support until permanent supports are installed.

Load Distribution

Shoring jack weights are designed to distribute loads evenly over a large area. They are placed under point loads to prevent settling or shifting of the structure being supported. This ensures that weight is distributed evenly thus preventing structural damage.

Adjustable Support

These weights are equipped with adjustable screws or hydraulic mechanisms. This allows for precise height adjustment and load compensation. This feature is particularly useful in uneven terrain or when supporting structures of varying heights.

Temporary Roof Support

Shoring jack weights are used to support roofs or ceilings during construction or renovation projects. This allows for safe access to work on the roof or ceiling structures without collapsing. They create a safe environment for workers to conduct their activities without incidences.

Bridge and Overpass Construction

These weights are used to support beams and girders during bridge construction. They allow for safe placement of heavy components and ensure structural integrity during the curing process of concrete.

Underpinning

Shoring jack weights are used in underpinning projects to support existing structures while strengthening or extending foundations. They provide controlled and stable support to prevent movement or settling of the structure being underpinned.

Weight Capacity

Shoring jack weights are used to support structures, so it's important to ensure that the shoring jack can support the desired weight. The shoring jack should be rated for the weight it will support. Look for shoring jacks with a weight rating that exceeds the weight capacity.

Construction Material

The material used to construct shoring jacks affects their weight, durability, and performance. Shoring jacks are commonly made of steel or aluminum. Steel is usually more durable and can support greater weight. Aluminum is lighter and easier to move around but may not support as much weight as steel.

Height and Adjustability

Shoring jacks come in different heights and adjustability levels. Consider the height of the shoring jack to ensure it can reach the desired height when supporting. Some shoring jacks have adjustable heights, which can be helpful when supporting structures of different heights.

Base Plate Size and Stability

The base plate size should be large enough to distribute the weight evenly on the ground. A bigger base plate will provide more stability. The stability of the shoring jack is important because it affects how well it can support the structure. Look for shoring jacks with a stable design and a good base plate size.

Ease of Use

Look for shoring jacks that are easy to operate, set up, and adjust. Features like simple operating instructions and good adjustment mechanisms can make the shoring jack easier to use. Also, consider how easy the shoring jacks are to move around and set up on-site.

Price and Value for Money

The price of shoring jacks can vary greatly depending on their features and specifications. While it is important to stay within budget, it is also important to consider the value for money. Look for shoring jacks that offer good value for money, which means they are durable and perform well at a reasonable price.

Q1: Are shoring jack weights the same as adjustable props?

A1: Shoring jacks weights are not the same as adjustable props. Although they are both used in construction projects, shoring jack weights are used to shore up a construction site and provide temporary support to weight loads, while adjustable props are used to support horizontal beams.

Q2: What are the types of shoring jack weights?

A2: There are several types of shoring jack weights based on their construction, including telescoping jacks, screw jacks, hydraulic jacks, and single and double-shoring jacks.

Q3: What are the advantages of shoring jack weights?

A3: Shoring jack weights provide temporary support to construction sites in order to prevent structural collapses or accidents. They are essential in the construction of any building since they provide support to walls, beams, and columns as they are under construction. They are also cost-effective and reliable.

Q4: What are the weight capacities of shoring jack weights?

A4: Shoring jack weights come in different sizes, designs, and weights depending on the type and purpose. They can range from 1 ton to 20 tons or more. The weight capacity is the load the jack can safely support, which is determined by the manufacturer.

Q5: What are the weight dimensions of shoring jacks?

A5: The dimensions also vary depending on the weight and type of shoring jack. For instance, the height can range from 2 meters to 6 meters or more. The base plate dimensions can also vary depending on the weight and type of jack.