(2212 products available)

Scaffolding shoring jacks are devices used in construction to support structures temporarily. They are essential in providing stability and support to beams, columns, and formwork during the construction of a building. Shoring jacks come in different types which include:

Adjustable Steel Support Jacks

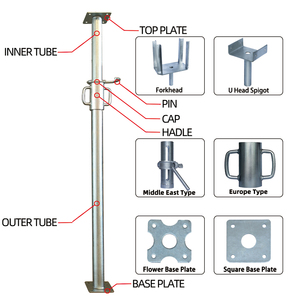

These are also known as construction support beams or propping jacks. They are commonly used in construction and building projects. They are used to support and stabilize structural elements like beams, walls, and columns. They are adjustable to allow for customization to fit different heights and support needs. Typically, they consist of a top plate, a threaded rod, and a base plate. The top plate is placed under the structure that needs support. The threaded rod is adjusted to change the height, and the base plate distributes the load to the ground.

Aluminum Shoring Jacks

These are lightweight and durable. They are made of aluminum material, which makes them easy to handle and transport. They are used to support formwork in concrete pouring. They come in various lengths and configurations and are adjustable to provide temporary support to structures under construction.

Heavy-Duty Telescoping Shoring Jacks

These jacks are designed to support heavy loads. They are made with high-strength steel and can handle significant weight without buckling or bending. They are usually used in major construction projects like bridges and high-rise buildings. They have multiple sections that slide in and out of each other to adjust the height. They are fitted with locking mechanisms to ensure stability and safety at the desired height.

Concrete Shoring Jacks

These jacks are specifically designed to support concrete formwork during the pouring and curing of concrete. They are constructed from high-strength materials to withstand the significant loads associated with concrete work. They are usually made of steel or aluminum. They provide adjustable and reliable support to ensure proper alignment and curing of concrete structures.

Fixed Support Jacks

These are non-adjustable support jacks. They provide permanent support to structures. They are designed to support beams, walls, and columns. They are non-adjustable, thus offering fixed support that cannot be changed or modified. They are used in constructions where permanent support is required.

Shoring jacks have a variety of features that improve their performance, safety, and ease of use. Here are some of the important characteristics of shoring jacks:

Load Capacity

The load capacity of shoring jacks varies depending on their size and construction. Commonly, they can support loads of 50 kN (about 5 tons) to 200 kN (about 20 tons) or more. Each jack is designed with a load capacity rating to ensure it is used within its limits.

Adjustable Height

Scaffolding shoring jacks are designed to be adjustable to different heights. This ensures that they can be easily adjusted to accommodate various construction needs and site conditions. Some hydraulic jacks can adjust their height automatically.

Construction Material

Shoring jacks are usually made of high-strength steel, which offers enhanced durability and resistance to buckling and bending. Some models can be constructed using aluminum, which is lighter and rust-resistant.

Base Plate and Toe Board

Most shoring jacks come with base plates that offer stability and load distribution. The base plates are usually welded or bolted to the jacks' bottom. Some have toe boards that prevent tools and debris from falling off the edge.

Easy to Assemble and Disassemble

These jacks are designed to be easily assembled and disassembled. This makes them versatile and reusable for different projects. Their assembly and disassembly process requires qualified personnel to ensure that everything is intact and functioning properly.

Compatibility

Shoring jacks are compatible with various components of shoring systems, including beams, plates, and props. This shoring jack provides a complete shoring solution for several construction projects.

Hydraulic or Mechanical Operation

Shoring jacks can be hydraulic or mechanical. Hydraulic jacks use hydraulic cylinders to lift and support loads, while mechanical jacks use screw or telescopic mechanisms. Hydraulic jacks are easier to operate and require less physical effort than mechanical jacks.

Safety Features

These include locking mechanisms, pressure gauges, and overload protection devices. Locking mechanisms secure the jacks at the required height, pressure gauges display the hydraulic system's pressure, and overload protection devices prevent the jacks from supporting excessive loads.

Maintenance and Care

The maintenance and care of shoring jacks are very important to ensure their longevity and proper functioning. This entails regularly inspecting them, cleaning, lubricating moving parts, and replacing worn-out components.

Scaffolding shoring jacks are essential in temporary support construction. Their applications are in various construction industries. Here are some of the most common application industries.

Construction

The scaffolding jacks are predominantly used in construction. They provide temporary support to structural components. These components are such as beams, columns, and slabs. The jacks are adjusted to ensure a level and secure support. This allows safe and efficient construction of multi-storey and high-rise buildings. Additionally, they support the formwork during concrete curing. This ensures a well-aligned and reinforced structure once the concrete is set.

Bridge Construction and Maintenance

The shoring jacks provide support during the building of new bridges. They also support auxiliary structures like cantilever formwork. This enables precise alignment and stability of the bridge deck during construction. Additionally, they are used in the refurbishment and retrofitting of existing bridges. The jacks are used to transfer loads and reduce stresses on the bridge components. This is especially during the installation of new structural elements and repairs.

Heavy Equipment Lifting

The shoring jacks can be used as load lifting equipment. They provide a safe and stable platform for lifting heavy equipment. This makes it easy to carry out maintenance and inspections. The jacks are also used for positioning and installing heavy machinery. They provide precise adjustment capabilities. This ensures proper alignment and placement of the machinery.

Geotechnical Operations

The jacks provide temporary support in excavation sites. They support retaining walls and shored systems. This prevents collapses and soil movement. Additionally, the jacks help in the installation of soil nails and micropiles. This offers a stable working platform and ensures proper alignment during the process.

Renovation and Remodeling Projects

The scaffolding jacks support existing structures. This allows safe removal of load-bearing walls and installation of new beams. This ensures the structural integrity of the building is maintained. Additionally, they provide support to overhead structures. These include ceilings and corbels during the renovation of historical buildings.

There are a few things to consider when buying shoring jacks in wholesale:

Load Capacity:

Understanding the construction project load requirements is important. This will help determine the appropriate load capacity for the shoring jack. Load-bearing capacity is usually expressed in tons or pounds. Each type of shoring jack has its own load capacity. So, it is important to choose the one that can adequately support the beams, structures, or loads to be propped.

Height Adjustability:

Construction structures come in different heights. So shoring jacks must be adjustable to support structures of varying heights. Height-adjustable jacks are versatile and can be used in different construction situations. When choosing adjustable jacks, check out those with a stable and secure height adjustment mechanism.

Material and Durability:

Shoring jacks are exposed to different environmental conditions, so they must be durable. It is important to choose shoring jacks made of robust materials that can withstand corrosion and weather elements. Look for jacks made with high-strength steel or aluminum alloy. Also, check out the material coating for corrosion resistance. They should have a galvanized coating or be painted with anti-rust substances.

Base Plate and Footing:

The base plate is the part of the shoring jack that rests on the ground and supports the weight. It is important to choose a jack with a base plate that distributes weight evenly to prevent sinking or tipping. Also, ensure there are adequate footings to support the shoring jack and the load it carries.

Compatibility:

Shoring jacks are compatible with different types of construction materials and structures. Ensure the shoring jack is compatible with the building material to avoid accidents. Read the manufacturer's guidelines to determine the compatibility of the shoring jack.

Ease of Installation and Removal:

Shoring jacks should be easy to install, remove and adjust. This helps save time and maximize productivity in construction.

Cost and Budget Considerations:

Shoring jacks are available at different prices. While it is important to consider the cost, it is also important not to compromise quality and safety for cost. Choose shoring jacks that fall within budget and provide the necessary support and safety.

Q1: Can someone use scaffolding shoring jacks for permanent applications?

A1: Usually, jacks are designed for temporary support during construction. Using them for permanent applications is not recommended since they are not designed for that purpose. They are meant to be used temporarily.

Q2: How many times can someone extend a shoring jack?

A2: Shoring jacks can be extended several times as long as they are properly maintained. The 6-foot jack can extend up to 10 feet, while the 8-foot jack can extend up to 12 feet. However, extending them beyond their recommended height is unsafe and not advisable.

Q3: Are shoring jacks the same as post shores?

A3: Although they perform similar functions, shoring jacks and post shores are different. Post shores are used as permanent structural support and are usually constructed using steel or aluminum. On the other hand, shoring jacks are temporary supports used in construction to support beams, slabs, and columns. They come in different lengths and are fabricated using high-strength steel.