(111 products available)

Ruled grating, also known as ruled gratings, are optical devices used in spectrometry for diffraction. The ruled gratings consist of thousands of lines that are etched or ruled onto a reflective surface. They are used to disperse light into its constituent spectrum. The light is divided into different colors based on the wavelengths. The types of ruled gratings are as follows:

Transmission Gratings

These types of grating allow light to pass through the surface. They are mounted on transparent substrates. The light is diffracted into various spectrums when it passes through the ruled grating. The transmission grating is further divided into two: Transmission Ruled Grating and Transmission Diffraction Grating.

Reflection Gratings

These ruled gratings reflect light instead of transmitting it. They are the most commonly used type of ruled grating. They are suitable for applications involving visible and near-infrared wavelengths. The light is diffracted and reflected back at specific angles. Reflection ruled gratings are also classified into two: First-order Reflection Grating and Higher-order Reflection Grating.

Blazed Gratings

Blazed ruled gratings have a saw-tooth profile. The profile is designed to concentrate the light energy into specific diffraction angles. The design allows for greater efficiency at particular wavelengths. The blaze angle and wavelength are application-specific. The gratings can be made for either transmission or reflection diffraction.

Ruled and Holographic Gratings

Ruled gratings are produced by mechanical ruling. The process creates a regular pattern of grooves. Holographic gratings are made using laser interference patterns. They allow for high precision and efficiency in light diffraction.

Variable Groove Density Gratings

These types of grating have sections with different groove densities. The varying densities enable the dispersion of a wide range of wavelengths. They are useful in applications requiring flexibility across different spectral ranges.

Phase-Varying Gratings

Phase-varying ruled gratings manipulate the light waves' phase front. The manipulation leads to efficient diffraction without relying solely on the amplitude variation of the grooves. They are mostly used in advanced optical systems.

Below are the features and functions of ruled gratings:

High Strength:

Steel ruled gratings have high strength and high load-bearing capacity. This makes them suitable for applications with high traffic loads, such as walkways and industrial platforms. They can withstand heavy impact and weight without bending or breaking.

Durability:

Steel gratings are durable. They are made with materials that have high resistance to corrosion and weathering. This ensures a longer lifespan and reduced maintenance costs. They can be used in harsh environments without deteriorating.

Safety:

Ruled metal floor grates have high slip resistance. They ensure safety in areas with high foot traffic or exposed to water and other slippery materials. They also provide drainage and prevent water pooling, which can cause slips and falls.

Lightweight:

Although steel is lightweight, ruled gratings are designed to be lightweight. This makes them easy to handle and install. They also reduce the load on supporting structures. Their lightweight nature doesn't compromise their strength and load-bearing capacity.

Versatility:

Ruled gratings are used in various applications and industries. They can be used in bridges, buildings, industrial plants, applications in oil and gas industries, and marine structures. They are suitable for different environments and designs.

Design Flexibility:

Steel ruled grating offers design flexibility. They are available in different thicknesses, sizes, and patterns. This makes them customizable for different applications and aesthetic preferences. They also have high aesthetic value and can be used to complement the design of buildings and structures.

Low Maintenance:

Steel ruled gratings require low maintenance. They are easy to clean and maintain. This cuts down maintenance costs and ensures safety. Their durability also ensures they don't wear out or break down easily.

There are many ruled grating applications across various industries. Application of ruled gratings includes:

When choosing a ruled grating, consider the following factors:

Material

The material used to make the gratings affects its performance and durability. Steel ruled gratings are durable and corrosion resistant. They are mostly used for industrial applications. Aluminum ruled gratings are lightweight and rust resistant. They are mostly used for models and scientific research.

Type of ruling

The type of ruling affects the optical performance of the grating. Straight ruled gratings are simple and inexpensive. They are used in applications that require low resolution. Blazed gratings are efficient and reduce stray light. They are used in applications that require high diffraction efficiency. Circular gratings produce spectra with multiple orders. They are used in compact spectrometer designs.

Pitch and groove density

The pitch and groove density determines the wavelength resolution and diffraction angle. Close spaced grooves produce high resolution diffraction patterns. They are used in applications that require precise wavelength separation. Coarse grooves are suitable for visible light. They are used in applications that require high intensity light.

Wavelength range

Different ruled gratings operate within different wavelength ranges. Selecting a grating that matches the light source wavelength is important. This ensures optimal diffraction efficiency. Some gratings are designed for UV light sources. Others are designed for near-infrared light sources.

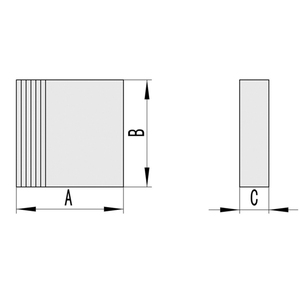

Size and format

The size of the ruled grating affects its compatibility with optical systems. They are available in different sizes and formats. It is important to select a size that fits the intended optical setup. Manufacturers provide gratings on square substrates or on microscope slides.

Customization

Some manufacturers allow customers to request for custom ruled gratings. When placing an order for custom gratings, it is important to provide all the necessary details. This includes the type of ruling, material, wavelength range, pitch, and groove density. It is also important to communicate the intended application.

Q: What is a ruling line?

A: The ruling line is a straight line that runs across the grating. It's located in the middle of the square or rectangular mesh. The line helps people see the square or rectangles clearly. It also shows the flatness and quality of the grating.

Q: What are the types of ruled gratings?

A: There are two main types of ruled gratings: Single Rule Grating and Double Rule Grating. The single rule grating has a ruling line. On the other hand, the double rule grating has two ruling lines that intersect at right angles.

Q: What are the applications of ruled gratings?

A: Ruled gratings are used for various applications in different industries. Some of the applications include: Academic Research, Astronomy, Spectroscopy, Optical Instruments, and Telecommunications.

Q: What are the advantages of ruled gratings?

A: Ruled gratings offer many advantages. They are durable and easy to use. The cost of producing them is also affordable. They provide high accuracy and reliability. Most gratings can be customized to meet different user needs.

Q: What are the disadvantages of ruled gratings?

A: The main disadvantage of ruled gratings is that they produce zero order light. This light can interfere with the intended spectrum. The effect of this interference can be reduced through proper beam shaping. However, it may require additional resources and expertise.

The keyword "ruled grating" has experienced significant fluctuations in web search volume over the past year, with an average monthly web search volume of 20. Notably, there has been a 100% increase in web search volume both in the last three months and over the last year. The detailed monthly data reveals a pattern of peaks and valleys: web search volumes peaked at 30 in January, April, May, and June, with notable lows of 10 in March, July, August, September, October, and again in December.

Analyzing the trend further, "ruled grating" web searches tend to peak around the beginning and middle of the year, with noticeable dips during the summer and towards the year's end. This pattern suggests a seasonal variation, where interest in ruled gratings increases possibly due to new school terms or office supply renewals, and then declines during holiday seasons or summer breaks.

The data indicates that while the overall interest in ruled gratings remains relatively low, the sharp increase in web search volume points to periodic surges in demand, likely tied to specific times of the year when school and office supplies are in higher demand. This trend could be useful for businesses in the school and office supplies category to plan their marketing and stock inventory accordingly.