Types of Rubber from China

Rubber from China is derived from the latex sap of rubber trees. After harvesting, the sap is mixed and coagulated to form solid rubber sheets. Rubber comes in many grades depending upon purity levels, processing methods, and intended uses. The global rubber market is huge, and with China's advances in rubber processing technology, they are one of the leading exporters. Rubber comes in two main types:

- Natrual rubber: Made from the sap of rubber trees, natural rubber is used to make tires, hoses, and belts. It provides excellent elasticity and strength. Rubber produced in China is used in various applications, from tires and footwear to industrial products. Natural rubber, also known as latex rubber, is made from the sap of rubber trees and provides excellent strength and elasticity. Rubber producers in China source latex from sustainable plantations and process it into sheets or blocks of natural rubber. Natural rubber is commonly used in tires, hoses, belts, and other rubber products that require superior stretch and resilience. It is also an eco-friendly material for gaskets, seals, and industrial components.

- Synthetic rubber: This type of rubber is manufactured from petroleum products. Synthetic rubber can be tailored to specific performance requirements, making it versatile and essential for many industries. It is available in various grades and compounds, allowing for customization to meet the needs of different applications. SBR, BR, and EPDM are commonly used synthetic rubbers for tire production, while neoprene and nitrile offer superior oil resistance for mechanical seals and hoses.

Other types of rubber imported from China include silicone rubber, polyurethane rubber, butyl rubber, and natural latex. Silicone rubber proves useful for high-temperature seals, while polyurethane rubber offers exceptional durability and flexibility for wheels, flooring, and other heavy-duty uses. China imports butyl rubber for making tires and inner tubes, while nitrile rubber proves essential for gaskets and hoses due to its oil resistance. Natural latex is a preferred eco-friendly material for molded products, adhesives, and rubber bands.

Function and features of rubber

The rubber has numerous applications, from industry and manufacturing to everyday use. The global rubber market was valued at $261 billion in 2021 and is estimated to grow at a compound annual growth rate (CAGR) of 3.3 percent, reaching $448 billion by 2030 (Statista). This indicates a steady demand for rubber materials in a wide range of markets.

Rubber materials are often classified into two categories: natural rubber and synthetic rubber. Natural rubber is derived from the latex of rubber trees, while synthetic rubber is produced using chemicals and polymers. Each type of rubber offers unique physical and functional properties that can be used in many applications.

- Elasticity, Flexibility, and Resilience: Rubber materials can be stretched significantly without breaking. Rubber products show remarkable elasticity and flexibility, making them suitable for applications where movement, expansion, or bending occurs. Rubber seals, gaskets, and hoses all exhibit resilient qualities that allow them to return to their original shape and size after deformation.

- Tensile Strength: Rubber products have high tensile strength, enabling them to withstand a high amount of stress or load without breaking. Rubber tires, belts, and cords are rein-forced with nylon or steel to increase their strength and durability.

- Thermal Insulation: Rubber products exhibit excellent thermal insulation properties that help maintain temperature and prevent the transfer of heat or cold. Rubber gaskets and seals provide effective thermal insulation in heating and cooling systems, preventing energy loss and maintaining efficiency.

- Anti Vibration and Noise Reduction: Rubber acts as an effective anti-vibration material and noise dampener. Rubber mounts, bushings, and pads absorb shocks, vibrations, and impacts, reducing noise and enhancing comfort in vehicles, machinery, and structures.

- Electrical Insulation: Rubber appears to be a good electrical insulator. Rubber gloves and mats are commonly used in electrical applications to provide safety and protection for workers and technicians while working on live wires or high-voltage equipment. Rubber hoses and cables have special coatings and insulation to prevent electrical conductivity and ensure safety in industrial environments.

- Hydraulic Properties: Rubber products exhibit good hydraulic properties and can withstand high pressure and fluid contact. Rubber gaskets and O-rings are used in plumbing, automotive, and industrial applications to create tight seals and prevent leaks.

Applications of rubber

China is one of the largest markets for rubber products, which range from general-purpose items to highly specialized rubber to meet unique industry needs. Rubber manufacturers in China produce over 5 million metric tons of rubber annually. They have a high production capacity and can supply large quantities to different industries. Some of the main applications of rubber produced in China include the following.

- Automotive: The automotive industry is the largest consumer of rubber. Rubber components are used in making tires, belts, hoses, seals, grommets, bushings, and non-structural body parts. China rubber suppliers provide a wide range of rubber grades to produce automotive parts that meet different performance and safety standards.

- Consumer goods: Rubber products are used to make various consumer items, including furniture, sporting goods, shoes, and toys. Furniture and sporting goods have rubber cushioning to enhance comfort and prevent damage. Rubber shoe soles and straps provide durability and flexibility. Rubber toys are safer for children because they are soft and flexible.

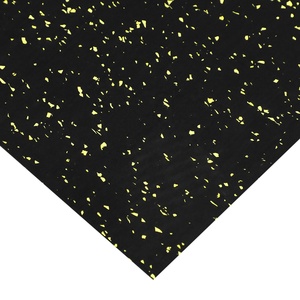

- Construction: Rubber roofing has gained popularity in the construction industry due to its durability and resilience. Construction companies also use rubber mats and tiles to make flooring for commercial buildings. These tiles provide a non-slip surface, while rubber mats are used as entryways to prevent dirt from entering the building, enhancing hygiene.

- Healthcare: Rubber is essential in the medical and healthcare industries. Rubber gloves are vital for protection in medical care, while gloves for personal use offer protection during cleaning and other tasks. Rubber tubes, sometimes called rubber China hoses, are used in the manufacturing of medical tools and equipment. Additionally, rubber is essential in making safety and CPR masks.

- Industrial applications: Factories and manufacturing plants use various rubber products to improve production efficiency. Rubber gaskets, O-rings, and seals are vital for all machinery assembly because they prevent leaks. Conveyor belts made from rubber are ideal for transporting goods because they are strong and can endure heavy loads.

How to choose Rubber China

Buyers should consider different factors when choosing Rubber China suppliers to ensure they partner with reliable manufacturers. Here are some tips and strategies that bulk buyers should implement when sourcing for rubber products or materials.

- Verify Rubber China Supplier Credentials: Rubber China suppliers deal in the manufacturing and distribution of rubber products in various international markets. It is important to conduct thorough vetting of suppliers to ascertain their legitimacy and credibility. Check for industry certifications, membership affiliations, and business licenses that prove expertise and adherence to accepted industry standards.

- Assess Product Quality: Request samples to assess the rubber quality and production workmanship before making bulk orders. Evaluate the rubber's texture, flexibility, durability, and resistance to abrasion and chemicals, among other physical features. Rubber products ought to remain intact and functional, even in demanding conditions.

- Inquire About Production Capabilities: Suppliers' ability to meet bulk order demands within the required timelines is determined by their production capacity. Therefore, assess whether they have the necessary machinery, workforce, expertise, and resources to manufacture rubber products consistently and determine whether they can meet any special requests and customization needs to satisfy specific requirements.

- Consider Specialization: Specialization allows suppliers to develop unique products that target specific industrial sectors. Buyers can find specialized rubber products or materials by partnering with Rubber China suppliers who focus on particular niches. Research the supplier's specialization and examine if it aligns with a specific product demand.

- Examine Compliance with Industry Standards: Buying rubber materials and products that adhere to international quality standards is important.| To ensure buyer compliance with safety regulations, inquire whether the supplier's rubber products meet industry standards and certifications such as CA61.358, ASTM, ISO, or RoHS.

- Delivery and Logistics: Evaluate the supplier's shipping methods, packaging standards, and delivery timelines. Find out if they are well-versed in customs procedures and international trade regulations. Timely delivery will ensure that production schedules are maintained and that there are no stock shortages.

- After Sale Support: Inquire about the supplier's after-sale policies and customer support. Effective communication channels and responsive customer assistance can help address any issues that arise after placing bulk orders.

Rubber China Q and A

Q: Does all rubber produced in China come from Chinese plants?

A: Not really. China is a major producer of synthetic rubber, which is made from petroleum products. They also import natural rubber from countries like Malaysia and Indonesia.

Q: What is the main type of rubber produced in China?

A: China mainly produces synthetic rubber, which includes a variety of rubber types like EPDM, SBR, and NBR. They make synthetic rubber in large amounts to use in car tires, hoses, gaskets, and other products.

Q: Does China export rubber products?

A: Yes, China exports rubber products to many countries. They export rubber tires, hoses, and seals.

Q: Does China have technology for making rubber?

A: Yes, China has advanced rubber production technology. They have modern rubber production machines and use high-tech methods to test quality.

Q: How should rubber be stored?

A: Rubber needs to be stored in a cool, dry place away from sunlight. Provide good air circulation. Keep temperature and humidity levels constant.