(46 products available)

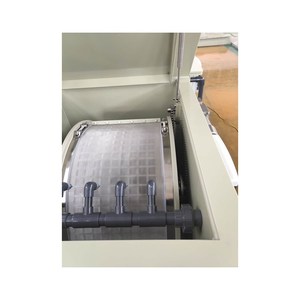

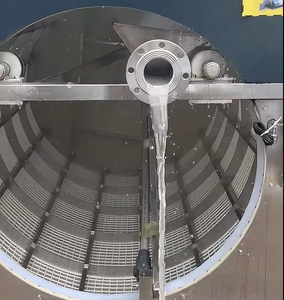

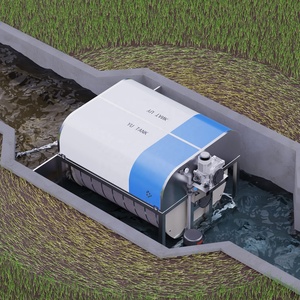

General purpose rotary drum filters utilize a partial immersion drum to filter a variety of clear to slightly cloudy feeds, commonly used in fish hatcheries and general water treatment. A band filter is a type of general purpose rotary drum filter that uses a single band replacing the circular filter surface to reduce the amount of filter media used. This not only reduces the cost but also enables the machine to process more wastewater in a given time, increasing the drum's filtering capacity and efficiency.

Rotary vacuum drum paddle filters are designed to deal with viscous or high-solids slurries. These types of filters do not use a vacuum to extract the filtrate from the slurry; instead, they use the movement of a paddle to help separate the liquid and solid materials. The paddle moves through the slurry and rotates back into a discharge area, in which the solids are dropped off.

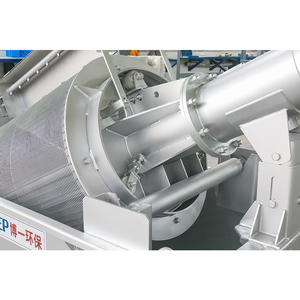

The hyperbaric rotary drum filter operates under pressure to produce a high-quality filtrate, an excellent alternative for wastewater applications demanding high-recovery rates and low-dosing systems. Depending on design requirements, models with or without backwash are offered. Filters without backwash typically have a higher filtration velocity, while those with backwash create a more extended backwashing pattern, improving filter efficiency.

The industrial applications of a rotating drum vacuum filter are diverse and pivotal for efficient separation processes across various sectors. One of the primary uses of a rotary vacuum drum filter is in the area of mineral processing and metallurgy. Here, the filters are essential for separating valuable minerals from slurries, concentrated liquids and even tailings.

A rotating drum vacuum filter also plays a pivotal role in the pharmaceutical and biotechnology industries by aiding the production of pure drug compounds. They do this by ensuring the separation of cell cultures, fermentation broths and other biological mixtures through precise filtration.

Many food and beverage production companies also use a rotary drum filter to separate solid and liquid food and beverage products. The filter is used to separate pulp from fruit juices, clarify edible liquids like oil and even process drinking water. Animal waste like manure from poultry, pig or cattle farms can be treated thanks to the vacuum drum filters. The filters separate the solid matter from liquids which makes for easier handling and possible solid materials recovery.

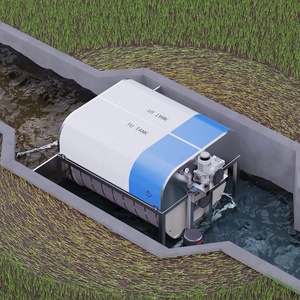

Another common application of the rotary drum vacuum filter in the environmental sector is in wastewater treatment facilities. Here, the drum filters are used to separate solids from municipal or industrial wastewater and effluent streams. The solid waste materials are then disposed of properly and the liquid that passes through the filter is further treated to make for cleaner effluent.

Manufacturing companies that produce chemicals, paints, coatings, and inks rely heavily on rotary vacuum drum filters to purify their products. The filters are used to separate contaminants, undissolved solids and even residual solvents from chemical processes to yield high products with minimal impurities.

Application:

Identify specific applications, including types of solid-liquid separations, material characteristics, and processing requirements. Ensure theselected filter is suitable for the given application to achieve optimal separation efficiency and performance.

Production capacity:

Consider the required production capacity based on factors such as processing volume, separation rate, and time constraints. Select a filter with a production capacity that meets the expected processing demands to ensure operational efficiency and productivity.

Filtration precision:

Determine the desired filtration precision based on the specific requirements of subsequent processes or product quality standards. Choose a drum filter that can achieve the necessary particle size separation to maintain the integrity and purity of final products.

Drum size:

Assess the available installation space and system integration requirements. Determine the appropriate drum size, including diameter and length, to ensure proper fit and integration within the existing setup while meeting processing needs.

Operation automation:

Consider the level of automation required for the filtering operation. Evaluate the need for automated control systems, monitoring capabilities, and safety features. Choose a drum filter that offers the desired automation level to enhance operational efficiency, ease of management, and safety.

Maintenance requirements:

Evaluate the maintenance requirements associated with the selected drum filter. Consider factors such as service intervals, maintenance procedures, and support availability. Choose a filter that balances maintenance demands and performance to minimize downtime and ensure reliable operation.

Q1: How large is a vacuum drum filter?

A1: The size of rotary drum filters varies among different models. Generally, the diameter ranges from 0.6 m to 3.6 m and the length ranges from 2.4 m to 10.8 m.

Q2: What are the recent trends in the vacuum drum filter market?

A2: The market is moving toward larger capacity-industrial scale filters. Advanced automation features are also becoming standard in many models.

Q3: How does the drum filter consume power?

A3: The filter consumes power in moving the drum and the air handling system that separates the water in the slurry into humid filtrate and vacuum-transparent tail gas.

Q4: How many types of vacuum filters are there?

A4: There are four commonly used vacuum filters in industry. They are the disc filter, the drum filter, the belt filter, and the leaf filter. Rotary drum filters are the most commonly used type.