(1141 products available)

A big rotary table is a large tabletop-like device that can be rotated to change the workpiece's position during machining. It is primarily used in metal machining factories to hold a workpiece with its larger surface area mounted to a table. These are several types of rotary tables that are commonly used.

Direct Drive Rotary Table:

A Drive rotary table directly connects 3D CNC machines for more straightforward work CNC cutters can quickly accomplish. A direct drive machine has less accuracy, higher spindle speed, and lower costs than other types of rotary tables. Nonetheless, it can do certain jobs directly instead of with an indirect gearbox. Some work is done at higher spindle speeds, so this method is less expensive and faster for some applications.

Servo Motor Driven Rotary Table:

A servo motor-driven work machine has limited speed and lowers work accuracy than an AC motor work machine. A servo motor moves an object in closed loop control by sending commands to the motor driver. The commands include a position where the servo must rotate its rotor and the time duration. It is less expensive than an AC motor-driven machine. Some industries use this because of its lower cost and the jobs its rotary direction can do efficiently.

AC Motor Driven Rotary Table:

This machine can do many jobs and is more accurate than a servo motor-driven machine. An AC motor work machine can rotate a motor speed higher than a direct motor drive motor. An AC motor works by changing the frequency to change how fast the motor turns. It's used when precision is more important than initial cost. Some industries may rent or purchase this work motor for high-precision work requiring its accuracy.

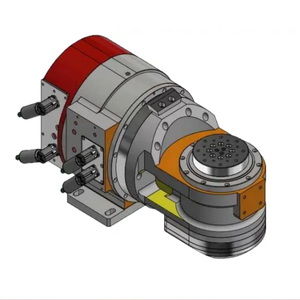

Multi-Purpose Rotating Table:

It is designed to help industries do immeasurable jobs by holding a workpiece with a wide surface area. It has T-slots to anchor a workpiece, douglas hinge positions to locate pieces accurately with down mules, and doubly draped positions to put pieces with an underdrift. Some areas of work that require a multi-purpose rotating table include surveying, metalwork, cutting, and machining. Other industries also do core sample analysis and forensics, and some may use it with small CNC machines when doing those jobs.

Indexing Fixture:

This fixture allows hard-to-reach work areas in an industry to access easily. Some difficult-to-reach work areas include welding, cutting, machining, and assembly. People can quickly reach these places because the fixture holds workpieces securely and rotates them so the user can see all sides, including the underside, while working at comfortable working angles. It improves safety and productivity, as this fixture can be done at a work table or machine.

Big rotary tables are key components in the machinery manufacturing industry. They offer the support and rotation speed required for high-precision parts during machining operations.

Plus, they help simplify job setup, making it easier to produce complex pieces without needing as many tools. Machinery manufacturers benefit from these tables, as they help improve product quality while shortening production times.

The heavy-duty rotary table also finds many uses in other industries. Below are some of them:

Some of the factors to consider when getting a big rotary table for sale are as follows:

Machine compatibility

A buyer needs to consider the compatibility of the rotary table with their existing machinery. Ideally, the rotary table should fit well with the current machine in use to ensure there are no assembly or operational issues. Pay attention to factors like the mounting dimensions and weight to ensure proper compatibility and functionality.

Workpiece needs

When selecting a big rotary table, it's crucial to consider the dimensions of the workpieces that will be its primary focus. Pay attention to the diameter and height of the workpieces to be rotated. It's important to choose a rotary table that can accommodate those measurements comfortably, allowing for smooth operation and efficient machining.

Speed and torque requirements

Depending on the specific machining tasks at hand, the speed and torque requirements of the work are likely to vary. When choosing a rotary table, it's important to consider the necessary speed and torque to meet the machining needs. Selecting a rotary table that provides the desired speed and torque ensures optimal performance and productivity during machining operations.

Precision and resolution needs

Basically, machining applications vary in their demand for precision and resolution. Hence, it's crucial to consider the required level of accuracy and positioning resolution when selecting a rotary table. Whether the job requires high precision or machined parts with high precision or not, choosing a rotary table that meets specific precision and resolution requirements ensures the quality and accuracy of the finished work.

Control system integration

For some buyers, who need to integrate a new rotary table into an existing production system, or who want to make their automated machining work more easy and seamless, the need to consider the ability of the rotary table to incorporate the control system they're using. It's essential to ensure that the table can connect and work efficiently with the desired control system, enabling smooth automation and streamlined production processes.

Q: What are some applications of a rotary table big?

A: Rotary tables are used in various industries big and small. One of the most common applications is constructing cylindrical parts. The tables are excellent for creating even grooves and achieving uniform drawing and stitching. Rotary tables assist welders in making circular welds, especially in piping. They help welders achieve consistent circular joints. Rotary tables are also used in jig boring and milling, where accurately drilled holes and milled designs are required.

Q: How does a rotary table work?

A: Generally, a rotary table has a powered rotating platform that turns or tilts workpieces. The axis of rotation is vertical. Workpieces are attached to the table's top side, and a motor or manual crank is used to rotate the base. Some tables have gears and pinions that assist in turning the workpieces.

Q: What are the different types of rotary tables?

A: Rotary tables can be classified based on their drive mechanism, design, and function. The commonly known rotary tables are the horizontal and vertical rotary tables. Another way of classifying the rotary table is the gear and pinion drive, belt drive, and servo motor and encoder drive.