Types of rotary table 5 axis

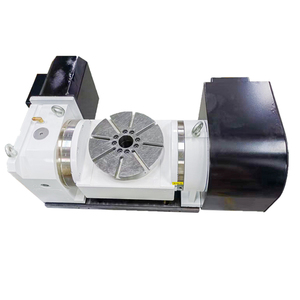

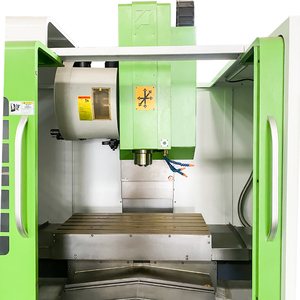

A 5-axis rotary table is a workpiece-holding device used in CNC machines that provides an additional three rotational axes (A, B, and C) on top of the two typically known (X and Y). It enables full three-dimensional (3D) cutting of an object, meaning the machine can effectively and efficiently cut complex 3D shapes by rotating the workpiece in three different directions. The table is mainly made of stainless steel, cast iron, and aluminum; these materials help protect it against rust or corrosion.

There are different kinds of 5-axis rotary CNC tables:

-

Universal Rotary Table

This is the standard type of 5-axis rotary tables often found in machinery industries with CNC milling machines. The table has two primary axis rotations, which are done mostly through dihedral gimbals and horizontal planes. These universal rotary tables can, for example, help engrave rings and other round objects customarily.

-

Spiral Gear Rotary Table

As the name suggests, this particular type of 5-axis table is based on the use of a worm and spiral gear to provide the different axis rotations. The worm and gear setup can provide very smooth and consistent movements, which are excellent for precision work, as is typically required in the machinery industry. One con of this gear table is that it may not be backlash-free.

-

Dividing Head Rotary Table

This rotary table divides workpieces into desired sections. It can go up to five axes. Dividing heads are generally used for machining workpieces with cylindrical features or repeated geometric patterns. Depending on the model type, a dividing head rotary table may have an automatic or manual control.

-

Indexed Rotary Table

An indexed rotary table can only move to set positions or index points. These tables are often used in conjunction with CNC machines that are primarily concerned with drilling and milling rather than complicated contouring.

-

Productive Automation Rotary Table

These types of rotary tables are staged and designed precisely for automation applications. They provide robotic picks with high stability and precision. They also come up with significant load capacities, which make them ideal for assembly line rotary table CNC machines where heavy items would have to go through the process.

Specification and maintenance of rotary table 5 axis

Specifications

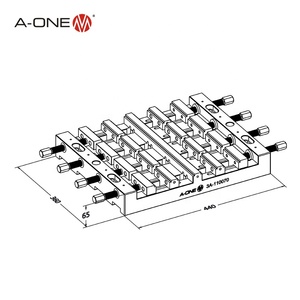

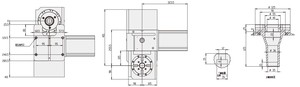

- Active Diameter: Size of the surface that's available for holding objects. For instance, a 5-axis rotary table may have an active diameter of 200mm, giving a working space of that circular size.

- Fitment: This is how it attaches to other tools, like a screw hole pattern. The rotary might have a fitting with holes far apart by 100mm square to bolt onto a machine.

- Max torque: Indicates how forcefully it can spin objects. A small table may have a torque of 10Nm, while bigger ones can have 50Nm or more because heavier parts need more twisting power.

- Weight: This is how heavy the rotary itself is, which partly determines its portability. A lightweight table weighs about 10kg, while heavier models might be 30kg or more.

- Control method: How the device is guided, whether by analog signals or digital coding. Many now take rotational commands digitally through G-code.

Maintenance

- Cleaning: Dust and metal debris after each use wipe with a soft cloth. Remove any blockages in the channels promptly. Occasionally, take out the rotary and clean the mounting surface carefully.

- Lubrication: Depend on the design. Use grease or oil at regular intervals as specified. Wipe excess substances off to avoid collecting dirt.

- Inspection: Check for parts like belts or chains to ensure they are not worn out. Look over couplings and electrical connections to make sure everything is secure. Look for the excessive play that might suggest internal damage. Address any fasteners that are loose with proper torque.

- Cooling: Do not overload rotational tables beyond their weight limits. This can cause overheating of the motors, damaging them. Make sure they are adequately cooled. Properly route cables to keep them from getting pinched or tangled during movement.

Usage scenarios for a 5 axis rotary table

The five-axis rotary tables have wide usage scenarios for several industries such as marine, aerospace, automotive, tooling, medical, and manufacturing, among others. Here are some key usage scenarios for a 5-axis rotary table.

- Machining complex parts: The five-axis rotary tables have the ability to move workpieces along five distinct axes. As a result, they have become an ideal tooling system for machining complex workpieces that require five-axis simultaneous machining. Such five-axis rotary tables are typically used with CNC machines.

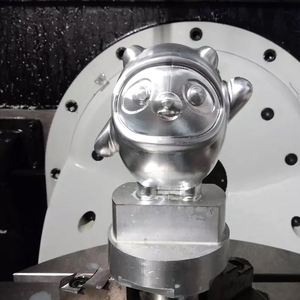

- Mold and Die Industries: The five-axis rotary tables are useful for the mold and die industries, which need to make highly sophisticated molds and dies. Thanks to their precision machining capacity, these devices are perfect for machining molds and dies for enclosed objects, such as molds for plastic products and casting molds.

- Medical Industry Applications: The medical industry buyers will often look for 5-axis CNC machines that work with a rotary table. These devices are perfect for machining medical equipment components like prosthesis implants, surgical instruments, and dental device parts. Such parts require a precise level of accuracy that 5-axis CNC machines can achieve.

- Prototyping and Product Development: CNC machining with 5-axis rotary tables makes it easy to accelerate product development and create prototypes in record time. The speedy machining operation they offer is unrivaled. Therefore, designers and engineers can use these devices to test new ideas rapidly and develop new products with ease.

- Aerospace Components: Parts made for the aerospace industry must be incredibly accurate, durable, and lightweight. Components like that call for an easy-to-use machining method with five-axis rotary tables. These machines support quick production and efficient manufacturing of complex aerospace parts like brackets, housings, and flanges.

How to choose a rotary table 5 axis

When shopping for a 5-axis rotary table, buyers should begin with determining their needs and budget. Next, they should research the available tables and shortlist those that meet their requirements. They can then compare their choices based on the following features and specifications.

- Working envelope: For a part-oriented rotary table, the working envelope refers to the maximum workpiece it can hold. The dimensions and weight have to be compatible with the table's design to ensure proper functioning. GEWEFA offers a rotary table with a 400 mm workpiece diameter and a maximum load of 250 kg.

- Accuracy and resolution: manufacturers specify rotary tables' positional accuracy and repeatability. Precision is necessary for achieving desired part quality. Remember that tables with high accuracy may have a higher price.

- Maximum speed and torque: These two factors determine how fast the table can move and how powerful it is. They are crucial for work efficiency and shortening production time.

- Motor type: The motor drives the rotary motion of the workpiece. Rotary tables may have servo motors for accurate positioning or stepping motors for less precision but at a lower cost.

- Control system: A rotary table's control system allows users to command its movement. Some tables have an independent controller, while others require a CNC with an additional input.

- Build quality: A rotary table's structural design and material determine its load-bearing capacity and durability.

- Power requirements: Suppliers provide specifications on the power input to operate the table. Many have AC power inputs with specific voltage requirements.

- Cost: The price range for 5-axis rotary tables is large. Buyers need to balance the cost against the features important to their application.

One way to make a direct comparison is to make a table with the features and specifications of interest for the rotary tables being compared. Remember to consider additional costs, such as those for installation, integration, and after-sales services, when choosing a supplier.

Q&A

Q: What are the two main types of rotary tables?

A: The two main kinds of rotary tables are the standard and the dividing rotary table. The standard rotary table is circular and flat, which allows for machining objects at various angles. On the other hand, dividing rotary tables have a mechanism that allows them to divide circles into preset fractional parts, which provides more precise control over the positioning and is suitable for creating intricate machined components.

Q: What is the difference between a rotary table and a power divider?

A: A rotary table is a machine tool accessory used primarily in milling machines for cutting circular objects or angles. Power dividers, on the other hand, are devices used to split power signals, usually in radio frequency or telecommunications applications.

Q: How does one calculate the feed rate for a rotary table?

A: The feed rate for rotary tables can be calculated by using the formula: Feed rate = Linear feed multiplied by table circumference divided by the number of divisions or circles required.