(1151 products available)

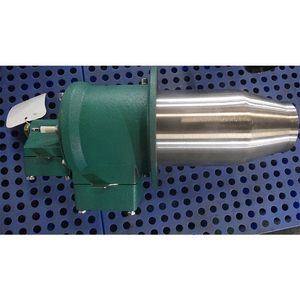

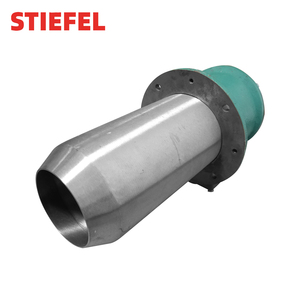

A rotary kiln burner is a crucial component of the rotary kiln, which provides the necessary heat to fuel the kiln for material processing. Rotary kiln burners are available in different types, each suitable for different fuel types and material processing requirements.

Rotary kiln burners can be classified into different types based on their specifications. The following are some of the most common types.

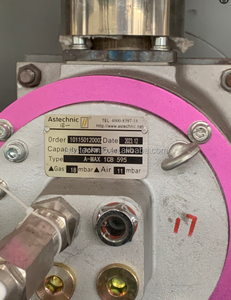

Capacity: Rotary kiln burners are available in different capacities, usually measured in tons per hour (TPH) of material processing. The capacity of the rotary kiln burner is determined by the heat output it can generate and its ability to maintain the required temperature for the processing materials at different feed rates. For instance, a low-capacity rotary kiln burner may have a capacity of 100 TPH, while a high-capacity one can go as high as 800 TPH.

Size and dimensions: The size of a rotary kiln burner can vary depending on the application and capacity requirements. The diameter and length of the burner affect the distribution of heat and the residence time of materials within the kiln. For instance, a standard rotary kiln burner can have a diameter of 12 to 15 feet and a length of 300 to 500 feet.

Heat source: Rotary kiln burners can operate using various heat sources. For instance, natural gas rotary kiln burners produce a clean and efficient fuel that is widely available. Propane burners are similar in design to natural gas burners but use propane fuel instead. They are often used as alternative fuel sources. Diesel rotary kiln burners are cost-effective and can be used for high-temperature applications. Finally, dual fuel rotary kiln burners can run on either natural gas or propane, depending on the availability and requirements.

Maintenance and service

Regular maintenance of a rotary kiln burner is essential for prolonging its lifespan and ensuring optimal performance. Manufacturers usually provide maintenance manuals with guidelines on how to inspect the burners.

Inspecting the components for signs of wear and tear is the first step in maintaining a rotary kiln burner. Users should look for any loose or damaged parts and promptly repair or replace them.

It is advisable to schedule periodic inspections and cleaning exercises to remove any dirt, dust, or debris that may accumulate in the burner and affect its performance. Regular cleaning will ensure the rotary kiln burner operates optimally and maintains the desired flame characteristics.

Most importantly, the burner should be operated within the recommended specifications to avoid premature failure.

The application of a rotary kiln burner is extensive and diverse, and its application scenarios are as follows:

In the metallurgical industry, a rotary kiln burner is mainly utilized in the production of lime and iron. In the iron and steel industry, the burner is used to produce iron ore and iron-containing raw materials, which are further processed into pig iron to create steel. Moreover, in the aluminum production process, the rotary kiln burner is used to produce alumina, a precursor to aluminum.

In the chemical industry, the rotary kiln burner is used for the calcination of minerals, such as the calcination of limestone to produce quicklime. Additionally, in the chemical industry, the burner is used to produce chemical products, such as calcium carbide, and to decompose various chemical materials through high-temperature treatment.

The application of the rotary kiln burner in the environmental protection industry is mainly embodied in waste treatment. The burner can be used for solid waste disposal through incineration, which can reduce the volume of waste and recover energy from the waste.

The application of the rotary kiln burner in the construction materials industry is mainly embodied in the production of cement. The burner is used to burn cement clinker, an essential material for the production of various types of cement. In addition, the burner is also used for the production of lime and lightweight aggregates.

The rotary kiln burner can also be utilized in the agriculture and forestry industries. In the agriculture industry, the burner is used for the production of fertilizers and soil amendments, such as phosphate rock calcination to produce phosphate fertilizers, which can improve soil quality and promote crop growth. In the forestry industry, the burner is used for the treatment of wood and biomass, which can process wood into charcoal and other valuable products.

When selecting rotary kiln burners, the following factors should be taken into consideration.

It is important to consider the operating parameters of the rotary kiln, such as the fuel type, feed material, heat requirements, etc. The selected burner should be suitable for the rotary kiln's specific operating conditions and requirements.

Consider the performance characteristics of the burner, such as heat output, temperature control, combustion efficiency, etc. Choose a burner that can meet the rotary kiln's performance needs and ensure stable and efficient operation.

Consider the burner's fuel flexibility, which includes the types of fuel it can use and the adaptability to different fuel properties. Select a burner that is compatible with the available fuel sources and can achieve optimal combustion performance.

Consider the burner's energy conversion efficiency, which affects fuel consumption and operating costs. Choose a burner with high energy efficiency and optimize the combustion process to minimize energy loss.

Consider the maintenance requirements of the burner, including the inspection, cleaning, and replacement of components, etc. Choose a burner that is easy to maintain and has a reliable after-sales service system so as to ensure timely support and assistance when needed.

Consider the environmental performance of the burner, such as emissions, etc. Select a burner that complies with environmental regulations and can achieve clean combustion to minimize environmental impact.

Consider the overall cost-effectiveness of the burner, including the initial investment, operating costs, maintenance expenses, etc. Choose a burner that can provide a good balance between performance, quality, and cost to maximize the return on investment.

Q1: What kind of burner does a rotary kiln use?

A1: A rotary kiln uses multiple types of burners, such as multi-fuel rotary kiln burners, natural gas burners, and fuel oil burners. Selecting the suitable type of burner for the rotary kiln depends on factors like the specific application, process requirements, and fuel availability.

Q2: What are the benefits of a high-efficiency rotary kiln burner?

A2: A high-efficiency rotary kiln burner offers benefits like improved thermal efficiency, reduced fuel consumption, lower emissions, and enhanced control of the combustion process. It also provides stable and uniform flame characteristics.

Q3: How to maintain a rotary kiln burner?

A3: Regular inspection and maintenance are essential for the proper functioning of a rotary kiln burner. Users should check for signs of wear, damage, or blockages and clean the burner regularly to ensure optimal performance. They should also follow the manufacturer’s maintenance guidelines and schedule and regularly inspect the fuel supply system and combustion air for any issues.