(149 products available)

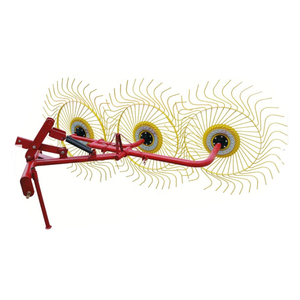

A rotary rake is a type of hay rake that uses rotating arms to gather and organize cut hay into neat rows or swaths for easier collection by balers or other equipment. Rotary hay rake manufacturers make rakes that can be towed behind a tractor or used as an attached implement. Here are some different types of rotary rakes.

Tractor-mounted rotary hay rake

A tractor-mounted rotary hay rake is an attached implement that is fixed to the three-point hitch system of a tractor. The rake is dragged along behind the tractor, and the hitch connects it at a higher point, which gives the operator more control and keeps the rake level. The powered rotary rakes use the tractor's PTO to drive the rotating raking arms that gather the hay. The PTO shaft connects to the rake shaft directly. Hydraulic-powered rakes will have hydraulic connections to power the rake's movement and rotation.

Towed rotary hay rake

A towed rotary rake is an unmounted implement that is towed behind a vehicle using a single-point hitch. The hitches connect to the rear of an ATV, UTV, tractor, or other vehicles. The height and angle are usually adjustable to match the vehicle and the terrain. Towed rotary rakes come in various sizes and widths to match the vehicle used and the area that needs to be raked. A towed rotary rake is best for larger areas and open fields. It is suitable for use with smaller vehicles like an ATV or UTV if the rake is small enough to be towed. It is usually used for gathering hay in areas where there are no obstacles.)

Pull-behind rotary rake

The pull-behind rotary rake is the same as a towed rake, where it is pulled by the raking teeth from the front. In this case, the user would pull the rotary rake toward themselves rather than dragging it along with a vehicle. Many farmers prefer pull-behind rakes because of their simplicity and ease of use.

Working width:

Farms and agricultural businesses should choose the rakes' working width per the hay field's size. A wider width helps in handling more hay in one go and boosts efficiency during the process of hay collection.

Number of wheels:

Wheels are important for ensuring the proper weight distribution of a rotary rake. The number of wheels affects the support to be expected and the overall ease of handling during operation. Generally, a rake with more wheels offers greater support and stability for various ground conditions.

Horsepower requirement:

The horsepower requirement of a rotary rake indicates the minimum power needed for efficient operation. Matching the horsepower requirement with available farm power and machinery helps in ensuring ideal performance during hay raking tasks.

Overall dimensions:

The overall dimensions of a rotary rake have an impact on storage space needs and maneuverability in fields or narrow areas. Proper considerations of dimensions facilitate easy storage and movement of the equipment when it is not in use or during the course of going from one field to another.

Businesses should carry out regular inspections of the rotary hay rake. In doing so, they can determine any sign of wear and tear. Also, they should pay keen attention to critical parts such as tines, belts, and gears. Scheduling periodic lubrication is also crucial. Farms can achieve longevity by having rotating parts tightly secured. Also, with frequent cleaning and removal of debris after use, farms can maintain optimal performance and efficiency of the equipment.

Due to their capabilities, pastures and fields can be left in a better state, making them ready for a second cut. A majority of grasslands can also be utilized by forage crops, which in turn can help reduce the livestock feeding costs.

Farming businesses with larger pasture areas can benefit greatly from having a rotary hay rake. Not only can they be taken out for use after rains, but they can also produce drier bales, thus increasing the number of quality hay harvested annually.

Areas that are rocky or have a lot of thatch on the ground can also be raked-up easily using a rotary rake, as it helps to lift the dry grass above, making it easier for new grass to grow. Swathes can easily be covered in large areas using a rotary rake, and no additional passes are needed, making it easier to cover large pastures in a short amount of time.

Since no constant contact with the ground is required, weather conditions need not be an important factor when using a rotary rake compared to other rakes. Even damp grass can be easily raked up with a rotary rake and taken out in one pass.

The main advantage of a rotary hay rake is the high speed and efficiency with which hay can be raked and collected, especially in large fields. The uniform fluffing of the hay also helps it dry quickly, minimizing the risk of spoilage.

For those looking to store the dry grass and winter feed in a barn, large round or square bales of hay can be prepared quickly and efficiently with a rotary rake. Not only does this save time when harvesting, but the quality of hay that can be stored for livestock during the winter months increases significantly.

Buying a rotary rake should not be based on hp alone. Tractor hp to rake size ratio is essential, but the field size and landscape also influence what should be bought. A small tractor with 25hp can efficiently work with a 6.5ft rotary rake in open fields, but in tighter spaces like valleys and slopped terrains, a smaller rake should be bought.

Durability is influenced by the materials used to make the rake. Durable rakes are usually made from high-grade steel and plastic. They can withstand harsh environmental conditions. Other things, such as operating speed and terrain, may put a rake's durability to the test.

Before deciding to buy a particular rake, consider the budget. New hay rakes are quite expensive, especially if they are large and have more rows of teeth. Early seasonal sales or late summer clearance are great opportunities to buy

Rotary hay rake manufacturers produce products that vary in price. Knowing the best time to buy and the features that influence the price will help buyers negotiate a fair deal.

Q: Which is better between a rotary rake and a disc rake?

A: Generally, disc rakes are more affordable than rotary rakes. However, they also consume more time and can be tedious to use. Rotary rakes are faster and more efficient. They also offer better functionality, allowing users to gather hay into windrows.

Q: Can a rotary rake handle wet grass when gathering hay?

A: While it is possible to gather wet grass using a rotary rake, it is not advisable. Handling wet grass can lead to matting, clogs, and damage to the rake. It is better to wait until the grass has dried, preferably after a hot and sunny day.

Q: How do users prepare for gathering hay using a rotary rake?

A: Before using the rotary rake to gather hay, one should ensure the field is clear of rocks and debris. Check the weather forecast and confirm windrows are on the field lines preferred by the local soil conservation. Familiarize the rotary rake manual and setup and adjust the rake for the specific crop type. Finally, ensure the rake is well-maintained to allow smooth and effective operation.

Q: Can a rotary rake be used for other crops apart from hay?

A: Yes. Besides hay, a rotary rake can be used for several crops, including sugar beets, potatoes, carrots, sunflower, and lettuce. However, it is important to note that ideally, a rotary rake is best suited for crops on grass or legume fields. Before using it on any other crop type, familiarize yourself with the manufacturer's instructions and recommendations.