(7226 products available)

The rock drill 20 is a large-sized rock drilling machine. There are two main categories of rock drill 20 as follows.

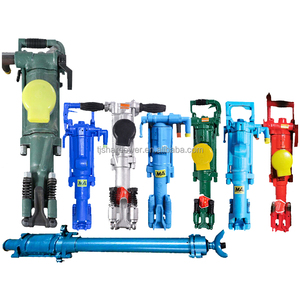

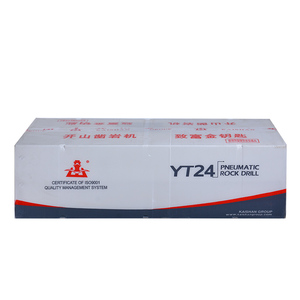

Pneumatic Rock Drill

The Pneumatic rock drill 20 uses compressed air to function. The air hose connection is visible on the machine. The compressed air fuels the hammer mechanism. Consequently, The drill bit strikes and digs into the rock. Pneumatic rock drills operate in quarries and construction sites. They are suitable for friendly and lightweight work environments. The benefit of the Drill 20 is its efficiency at high rates of air pressure. The downside is it requires a compressor and constant air supply to function.

Hydraulic Rock Drill

The Hydraulic rock drill functions similarly to the pneumatic model. The hydraulic system has a piston mechanism too. However, fluid pressure in the system fuels the movement of the piston. Consequently, this forces the drill bit to strike and excavate the rock. Hydraulic rock drills are ideal for heavy-duty mining applications. They work efficiently in deeper mines with tougher rock formations. They have greater power, control, and precision. However, they require an integrated hydraulic system and connection for operation.

Key specifications of the rock drill 20 include the power source, frequency, weight, drill pipe diameter, impact energy, drilling depth, dimension, water flushing system, working pressure, rock hardness, and air consumption.

It is necessary to maintain the rock drill to keep it in the best operating condition, extending its lifespan and reducing the need for repairs. The rock drill machine needs regular inspection to identify the required parts to fix, replace, or lubricate. During inspections, look for unusual signs such as noises, vibrations, and overheating, and check the drill bits for signs of damage or dullness.

Cleaning the rock drill prevents the buildup of dust and debris, particularly in the air passages and cooling fins. Waste removal also helps to avoid overheating and improves the drill's efficiency. Use the right lubricants on moving parts of the drill to reduce wear and tear and prevent overheating. Follow the manufacturer's instructions when applying the lubricant. Drilling machines work with different types of power sources, and their performance depends on the power supplied. Ensure that the drill is correctly connected to the air compressor or electricity. Regular calibration can help maintain the rock drill's drilling accuracy.

Due to its high efficiency and performance, the rock drill 20 is widely used in many industries.

Mining industry

The main application of rock drill 20 in the mining industry is to drill blast holes for the purpose of stone or mineral perfect extraction. Meanwhile, the rock drill can also be used to drill holes for the installation of rock support or bolt, which can help to improve the stability of the rock mass.

Construction

The rock drill 20 is really a vital equipment for the demolition and construction of various building projects, such as tunnels, foundations, roads and so on. It is able to make holes in hard rock or concrete in order to create the space for the building or construction.

Infrastructure development

Rock drill 20 can also be used in some projects of infrastructure development, for example: the drilling of holes for the installation of piles as well as the excavation of holes for the foundations. Meanwhile, rock drills can also be applied to roads and tunnel projects by drilling cracks and expanding space.

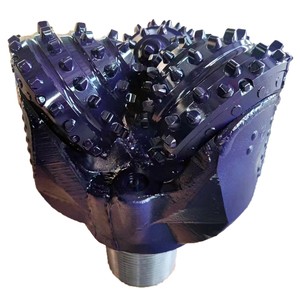

Oil and gas industry

In the oil and gas industry, the rock drill 20 can be used to drill oil wells or gas wells in order to establish the channels for the extraction of resources.

Groundwater exploration

Rock drills can also be used in groundwater exploration by drilling holes to look for groundwater.

Geological survey

With its precise and efficient drilling function, the rock drill 20 can be used in the field of geological survey by drilling sample holes to collect geological samples. In this way, the geological features will be known and the understanding of the area will be improved.

Environmental remediation

As for the environmental remediation, the rock drill 20 can be used to deal with some contaminated sites by drilling and excavating to make the remediation agents or additives evenly distributed.

Both electric and air-powered rock drills have several benefits and features that buyers should notice before making an order.

Drilling capacity and diameter

When picking a rock drill machine, buyers should consider its diameter and drilling capacity. The ideal drill has a diameter that can easily pass the rocks without wallowing or getting stuck. Also, buyers should pick a drill with a maximum drilling capacity that suits their rock type and project requirements.

Power source

Rock drills usually have different power sources — electric or air-powered. An air-powered rock drill tends to be lighter and more durable. It also works well in humid or low-temperature settings. On the other hand, electric drills offer more torque and tend to be quieter. They are well-suited for projects in tight spaces that require digging deeper. Depending on the project requirements, buyers should get a drill with the perfect power source.

Control system and operator ergonomics

Control system and ergonomics are other important factors to consider when choosing a rock drill. Controls should be easy and intuitive to use. Also, it should have well-balanced weights plus adjustable seating and controls to ensure a comfy operation.

Rock drill type and shank compatibility

There are different types of rock drills, each designed to perform a specific task. Before ordering, buyers should take time and research the rock drill that suits their project. Additionally, buyers should get a rock drill compatible with the shank of their existing drill. This helps to improve efficiency and avoid the hassle of adapting different systems.

Maintenance and service accessibility

Buyers should get a rock drill with a maintenance system that's both easy and accessible. Also, they should choose a model with support services and spare parts availability. This helps to ensure long-term machine reliability and performance.

Q1: What type of drill bit does a rock drill use?

A1: The rock drill uses a tapered drill bit or a threaded bit. Commonly used bits with rock drills include TE, T, and RT bits.

Q2: What is the power source of a rock drill?

A2: The power source of a rock drill can be electric power, air power, or gasoline power.

Q3: Are rock drills dangerous?

A3: If not handled properly, rock drills can be dangerous. They can cause injuries like broken bones, power-driven tool injuries, and rock fragments and may result in occupational hazards like hearing loss from high noise levels. Using personal protective equipment can reduce the risks.

Q4: How deep can a rock drill go?

A4: Depths for drilling with rock drills vary depending on the drill model and manufacturer specifications. In general, depth from 50 meters to over 1000 meters can be achieved.