(1563 products available)

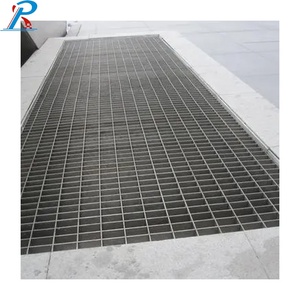

Steel road grates, often called steel floor grates or steel bar grates, are used in various applications, including roads, walkways, platforms, and industrial areas. They are composed of longitudinal steel bars linked by crossbars. This construction makes them very stable and durable. Steel road gratings are perfect for areas that need high traffic and heavy loads. They have a high load capacity and are resistant to rust. Steel road grates come in different types and sizes, depending on the use and requirements. The types of roads steel grating include:

Slip-resistant steel grating: Slip-resistant steel grates have a textured surface that provides traction and prevents slipping. They are used in areas with high foot traffic and exposure to water, like industrial walkways and parking garage ramps.

Heavy-duty steel grating: Heavy-duty steel grating is designed to support a lot of weight. They have thick and flat bars. They are used in places that experience heavy loads, like loading docks and industrial facilities.

Composite steel grating: Composite steel grating is made of steel and other materials, like fiberglass. They are lighter than standard steel grates and offer good drainage and slip resistance. They are used in chemical plants and coastal regions.

Electroforged steel grating: Electroforged steel grating is created using a high-temperature welding process that forges intersecting bars. The result is a strong and rigid grate that can support heavy loads. They are used in heavy-duty applications, like power plants and steel mills.

Welded steel grating: Welded steel grating is constructed by welding cross bars to the main steel bars. They are very durable and have high load-bearing capacity. They are used in industrial applications like platforms and machine enclosures.

Swaged steel grating: Swaged steel grating is made by inserting and swaging cross bars into the bearing bars, creating a rigid and stable structure. They are lightweight and ventilated. They are often used in sewage treatment plants and waste management facilities.

Pressed steel grating: Pressed steel grating is constructed by pressing and deforming cross bars into bearing bars. This creates a strong and stable structure. They are used in industrial applications and can handle heavy loads.

Barbecue steel grating: Barbecue steel grating is specifically designed for grilling. They have a flat and non-slip surface that is resistant to rust and easy to clean. They are used in outdoor and residential grilling systems.

Strength and Durability:

Steel road gratings are known for their exceptional strength and durability. They can withstand heavy loads and are suitable for various applications. This makes them ideal for demanding environments such as industrial sites, construction sites, and utility areas.

Corrosion Resistance:

Road steel gratings offer long-lasting performance even in harsh environments. They are designed with corrosion resistance in mind. For example, hot-dip galvanization or powder coating is used to enhance their durability.

Heavy Duty:

These gratings are capable of handling high traffic and heavy machinery. They provide reliable support and stability in areas with constant vehicle and pedestrian movement.

Excellent Drainage:

Road steel gratings provide excellent drainage. Their open grid pattern allows for the swift passage of water and other liquids, preventing accumulation and potential hazards. This makes them ideal for use in walkways and roads in areas with high rainfall.

Slip Resistance:

Enhanced safety is offered by the slip-resistant surface of road steel gratings. This feature is crucial for areas exposed to moisture or oil, reducing the risk of slips and falls for pedestrians and workers.

Versatility:

Road steel gratings come in various types, sizes, and configurations. This feature makes them suitable for different applications. This includes manhole covers, trenches, drainage covers, and areas surrounding utility boxes.

Low Maintenance:

Road steel gratings require minimal maintenance due to their durability and corrosion resistance properties. Regular cleaning and inspections are sufficient to keep them in good condition, which saves time and maintenance costs in the long run.

Aesthetic Appeal:

These steel gratings have a sleek and modern look that can enhance the overall aesthetic of any application. From architectural designs to outdoor spaces, steel gratings provide a functional and visually pleasing solution.

Eco-Friendly:

Road steel gratings are manufactured from recyclable materials. This makes them an environmentally friendly option for construction and infrastructure projects. Their longevity and durability also contribute to sustainable practices by reducing the need for frequent replacements.

When purchasing road steel grating, it is necessary to consider different factors to ensure the right product has been selected. The following are some of the factors to take into account:

Application requirements

Different applications require different types of road steel gratings. It is important to consider the application to ensure the road steel grating is used for the right purpose. Road steel grating is used for different applications like walkways, decking, and drainage covers. Each application requires a different type of road grating.

Load capacity

Another factor to consider is the load capacity. Road steel grating is available in different load ratings. It is important to select a load rating that can support the weight. Choosing a load rating that can support the required weight will cause safety hazards while choosing one that is too much will be a waste of money.

Environmental conditions

The environmental conditions of the area where the road steel grating will be installed play a major role in its selection. Some types of road steel grating are better suited for specific environmental conditions. For example, some types are better suited to corrosive environments like coastal areas or chemical plants. Others are better suited for areas with extreme temperatures.

Maintenance requirements

All types of road steel grating require maintenance to some extent. However, some types require more maintenance than others. For example, galvanized steel road gratings require regular maintenance in areas with extreme temperatures. On the other hand, stainless steel road gratings require little or no maintenance. Therefore, it is important to consider the maintenance requirements before settling on a particular type.

Aesthetics

Aesthetics is an important factor to consider when the road steel grating is used in walkways, driveways, or any other area that is visible. This is because one will want a road grating that complements the surroundings. When choosing based on aesthetics, one can choose either painted or galvanized road steel grating.

Q1. What are the advantages of roads steel grating?

A1. Steel grating is lighter than solid metal sheets. It is also stronger and more durable than other materials such as aluminum or fiberglass. Steel roads are easier to manufacture and install, saving time and money.

Q2. What are the disadvantages of roads steel grating?

A2. Steel grating has high maintenance requirements because it is prone to rust. It also has less corrosion resistance compared to other materials. Steel roads can be uncomfortable to walk on and may cause injuries due to their sharp edges.

Q3. How is steel grating maintained?

A3. The steel roads should be cleaned regularly to remove debris and dirt. They should be inspected frequently to identify any signs of damage or rust. Steel grating should be painted or galvanized to enhance its corrosion resistance.

Q4. How is the load capacity of steel grating determined?

A4. The load capacity of steel grating is determined by the thickness of the steel bars, the spacing between the bars, and the type of steel used. Load capacity can also be affected by external factors like temperature and humidity.

Q5. Are there non-slip options for roads steel grating?

A5. Yes, there are non-slip options for roads steel grating. These include galvanized steel grates with slip-resistant coatings or textures and serrated steel grates with welded or pressed serrated edges that provide better traction.