(1937 products available)

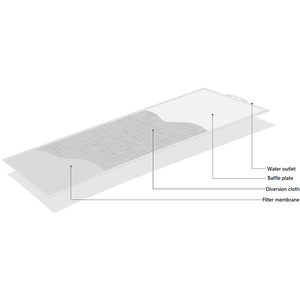

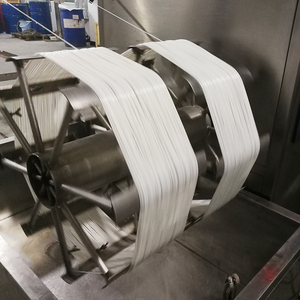

There are two major types of reinforced PVDF hollow fiber membranes: natural and bioreactor (MBR) wastewater treatment plants. Both are used in filtration for drinking and wastewater treatment, desalination, food and beverage clarification, and filtration, separations, pharmaceutical, sterility, air treatment, and industrial gas treatment applications.

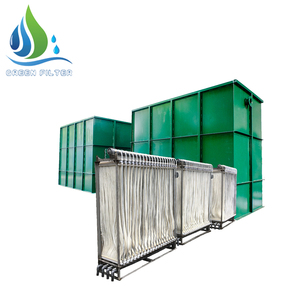

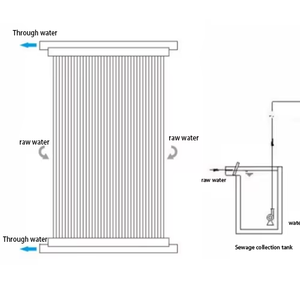

A prime application of reinforced PVDF hollow-fiber membranes is in waste treatment by using MBR plants. These MBRs have distinct benefits like not requiring further treatment for the wastewater to be recycled and high separation efficiency. In an MBR system, the membrane works in conjunction with a reactor to separate mixed organic matter at a cellular level. The membrane makes sure that only treated water permeates through, while bacteria and organic matter remain trapped and decomposed in the reactor. Membrane bioreactor technology thus provides a solution for high-quality wastewater treatment and has led to the development of several urban and industrial MBR systems.

There are two subtypes of the MBR that reinforced hollow fiber membrane manufacturers make:

The PVDF hollow fiber membrane has many specification parameters to meet different separation and filtration needs.

The application of reinforced PVDF hollow fiber membranes is dependent on the subject industry.

Water treatment

In the domain of water treatment, the reinforced PVDF membrane is utilized for a host of tasks. The fibers assist in the purification of both potable and residual waters. The fibers also contribute to the desalination process, taking out salts and other impurities from saline water to make it fit for consumption. Additionally, they are employed in the separation of various contaminants such as organics, heavy metals, and suspended solids from water.

Food processing

Within the food processing industry, the reinforced hollow fiber membranes find usage in multiple applications. They are employed in the microfiltration of food and beverages such as juices, wines, and dairy products, which aids in the removal of bacteria, yeasts, and particulates. The membranes also assist in the ultrafiltration of liquids to concentrate and purify various food products. Moreover, they are utilized in the separation and purification of food components such as proteins, carbohydrates, and lipids.

Pharmaceuticals

In the pharmaceutical industry, the reinforced hollow fiber membranes are indispensable. They are utilized for sterile filtration of liquids and gases, ensuring the removal of pathogenic microorganisms and ensuring product sterility. The membranes also assist in the microfiltration and ultrafiltration of solutions, which contributes to the purification and concentration of drugs, enzymes, and other biomolecules. Additionally, they are employed in the separation and removal of contaminants, impurities, and endotoxins from pharmaceutical substances.

Industrial processes

Reinforced hollow fiber membranes have diverse applications in industrial processes. They are employed in the gas separation of various mixtures, allowing for the selective removal or recovery of specific gases such as oxygen, carbon dioxide, nitrogen, and hydrogen. In the petrochemical industry, for example, they assist in the separation of hydrocarbons and other chemical compounds. They are also used in the microfiltration and ultrafiltration of industrial effluents and liquids, which helps to treat and recycle water in manufacturing processes.

Construction

In the construction industry, reinforced hollow fiber membranes are widely used. They are employed in the microfiltration of construction site water, which prevents the discharge of pollutants into the environment. The membranes are also used in the separation and recovery of industrial process streams, contributing to water conservation and sustainable construction practices. Additionally, they are utilized in the treatment of groundwater and surface water for reuse in construction activities.

When choosing a certain type of membrane, some factors and testing parameters need to be considered by buyers.

Physico-chemical properties of the membrane:

The surface chemistry, charge, hydrophobicity, and pore structure of the hollow fiber membrane can all affect the adhesion of the colloidal particles to the membrane.

Operating conditions:

The temperature, pressure, and cross-flow velocity during membrane filtration can also affect fouling. For instance, higher transmembrane pressure may improve filtration flux but lead to more severe fouling.

Interactions between the colloidal particles and the membrane:

The particle size and shape, concentration and ionic strength of the suspension, and the electrostatic and steric interactions between the particles and the membrane can also affect fouling.

Fouling control methods:

It is important to note that the choice of membrane PVDF along with the fouling control method used. Such as cleaning regimes and pre-treatment processes can significantly affect the operating efficiency of the membrane.

By carefully selecting and optimizing these factors, one can minimize the adsorption of colloidal particles and other substances onto the hollow fiber membrane, thereby reducing fouling and maintaining high filtration performance.

Q: Why are hollow fiber membranes preferred over others?

A: Hollow fiber membranes are compact and efficient. Their tubular structure provides a large surface area for filtration within a small footprint. This feature makes them suitable for industrial-scale operations where space is limited.

Q: Where does the future of hollow fiber membrane technology lie?

A: Innovations like smart membranes that change behaviour when stimulated or self-cleaning membranes are on the horizon. Reinforced hollow fiber membranes offer great potential in diverse fields, and research will continue to unlock new applications.

Q: What are the drawbacks of hollow fiber membranes?

A: Vulnerability to fouling is a significant concern. Particles, bacteria and algae can build up on the membrane surface, reducing filtration efficiency. Regular cleaning is essential, but harsh chemicals can damage delicate hollow fiber structures.

Q: Do hollow fiber membranes allow gas exchange?

A: Yes. Gas-permeable hollow fibers have micropores that enable gases like oxygen and carbon dioxide to pass through while retaining liquid. They are ideal for bioreactor systems where cells need sufficient oxygen to thrive.

Q: How long do hollow fiber membranes last?

A: Membrane lifespan depends on use, material and care. Durable reinforced membranes can last over 10 years with proper cleaning and maintenance. Regular cleaning prolongs life. Aim for optimal performance and avoid premature replacement.