Introduction to Refractory Castable Blast Furnace

Refractory castable blast furnace material is a crucial element in high-temperature industrial processes. Designed to withstand extreme heat and corrosive environments, these materials play an essential role in various industries, including metallurgical and foundry operations. Refractory castables are a blend of fine aggregates, cement, and additives that, when mixed with water, create a dense and durable material ideal for furnace linings and other high-temperature applications. This refined solution ensures the longevity and efficiency of blast furnaces, making it a vital component for any operation reliant on extreme thermal conditions.

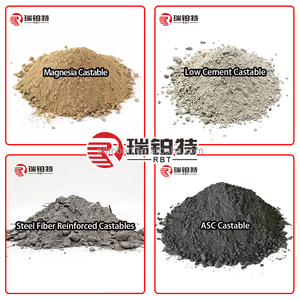

Types of Refractory Castable Blast Furnace

Refractory castable materials are categorized based on their composition and the specific requirements of their application. Understanding the different types is crucial for ensuring optimum performance in the desired scenario. Below are the primary types:

- High Alumina Castables: These are formulated with a high percentage of alumina, offering exceptional strength and thermal stability, making them suitable for various furnace linings.

- Low Cement Castables: This type features reduced cement content, enhancing density and resistance to thermal shock and slag erosion.

- No-Cement Castables: These innovative formulations utilize alternative binding agents, providing excellent refractory qualities and ease of application.

- Insulating Castables: Designed to minimize heat loss, insulating castables maintain temperature while reducing energy costs in furnace operations.

Applications of Refractory Castable Blast Furnace

The application of refractory castable blast furnace materials is vast, touching many sectors that require efficient thermal management. Its remarkable versatility makes it applicable in various scenarios:

- Metallurgical Industries: Used extensively in steelmaking processes, blast furnace linings made of refractory castables ensure structural integrity under intense conditions.

- Ceramic Industries: These materials serve as a foundational component in kilns and furnaces for hardening ceramics and other heat-resistant products.

- Cement Production: Refractory castables are essential in rotary kilns, where they stand against extreme temperatures and corrosive chemicals.

- Glass Manufacturing: High-temperature applications such as glass tanks require robust thermal linings that can endure abrupt thermal cycles.

Features and Advantages of Refractory Castable Blast Furnace

The unique features of refractory castables for blast furnace applications set them apart, providing several advantages:

- Durability: Built to last, these castables resist wear, thermal shock, and chemical attacks, significantly extending the life of furnace linings.

- Versatility: Capable of being molded into various shapes and forms, refractory castables can accommodate a range of designs to meet specific operational needs.

- Enhanced Thermal Insulation: Many formulations provide excellent thermal resistance, minimizing heat loss and improving overall energy efficiency.

- Quick Installation: Refractory castables can be cast in place or shaped in molds, facilitating straightforward installation and reducing downtime during maintenance.

- Cost-Effectiveness: Their long service life and low maintenance frequency contribute to lower operational costs over time.