(294 products available)

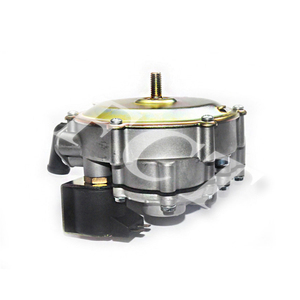

The reducer ngv is used in NGV systems to reduce the high pressure of natural gas to a lower pressure suitable for use in the engine. There are several types of reducers, each with its own unique features. They include the following:

Diaphragm Reducer

This type of reducer uses a diaphragm to sense the pressure of the gas in the ngv cylinders and in the intake manifold. When the pressure difference pushes the diaphragm, it opens or closes a valve to regulate gas flow. It is the most common type of reducer ngv due to its simple design and reliability.

Membrane Reducer

It is similar to the diaphragm reducer, but it has a membrane that provides a more sensitive response to pressure changes. It offers finer control over gas flow and is used in high-performance ngv systems where precise air-fuel ratio is critical.

Electronic Reducer

This is a modern type of reducer used in NGV systems. It uses electronic sensors and controllers to monitor and adjust gas pressure and flow in real time. It provides precise control, optimizes engine performance, and reduces emissions. Electronic reducers are common in new generation vehicles designed for NGV.

Spring-loaded Reducer

In this type of reducer, spring tension is used to regulate the force in the expansion chamber. The tension is adjustable to control gas pressure at the engine rail. The spring-loaded reducer is widely used due to its adjustability and suitability for different engine requirements.

Dual-stage Reducer

This type of reducer has two stages of pressure reduction. It reduces the pressure of the gas from the cylinders to the inlet manifold in two steps. First, it reduces the pressure to an intermediate level and then to a lower pressure suitable for the engine. Dual-stage reducers provide smooth gas flow, improving engine performance and reducing emissions.

Water-cooled Reducer

This type of reducer has a water cooling feature that helps to cool down the gas after it has been reduced. It is mainly installed in trucks and heavy-duty vehicles that operate for long hours. The water-cooled reducer prevents overheating, ensuring reliable operation and longevity of the reducer.

Every reducer ngv has its specifications that make it suitable for various applications. Here are some common specifications to consider:

Pressure Rating

Each ngv1 reducer has a pressure rating that indicates the maximum pressure it can handle. This rating is important for safety and performance in high-pressure ngv systems. The pressure rating is usually indicated in psi or bar.

Flow Rate

The flow rate of a reducer ngv is a measure of the volume of gas it can transport per unit of time. The flow rate is measured in standard cubic feet per minute (SCFM) or liters per minute (LPM). A high flow rate ensures efficient gas transport without delays or blockages.

Size and Dimensions

NGV reducers are available in different sizes and dimensions to suit various ngv systems. The size of a reducer ngv is determined by the diameter of its inlet and outlet connections. Common sizes range from 1 inch to 4 inches or more. The dimensions of a reducer ngv affect its compatibility with other components of the ngv system.

Material Construction

An NGV reducer is made from robust and long-lasting materials for dependability and safety. For instance, many reducers are made of steel or aluminum because of their corrosion resistance and strength properties.

Temperature Range

Every NGV reducer has a temperature range for optimum operation. This includes the minimum and maximum temperatures that the reducer can withstand without damage or performance degradation. The temperature range is crucial for ngv systems operating in extreme environmental conditions.

Maintaining the reducer ngv is essential for its long life and optimal performance. Here are some general guidelines for maintaining the reducer ngv:

Choosing the right NRG reducer is crucial for ensuring safety and optimal performance in any application. Here are some tips for choosing the right NRG reducer.

Understand the application

Understanding the application refers to considering the specific use aspect of the NCG reducer. This includes understanding the type of gas carried out by the reducer, the pressure requirements, and the flow rate needed in the application.

Quality and reliability

Quality and reliability are crucial for the NCG reducer's reliability. It is important to choose a reliable and trustworthy manufacturer or supplier whose NCG reducers are of high quality and consistent to ensure long-lasting and stable performance.

Compliance with standards

Compliance with standards refers to the NCG reducer meeting the relevant industry regulations and safety standards. This aspect ensures that the NCG reducer is safe, reliable, and effective in its application, minimizing risks and maximizing efficiency.

Ease of installation and maintenance

Ease of installation and maintenance is an important consideration when selecting an NCG reducer. It is important to choose a reducer that is easy to install and maintain, which can save time and reduce costs, thereby improving efficiency and reliability.

Cost-effectiveness

Cost-effectiveness is an important consideration when selecting an NCG reducer. While quality and reliability are important, it is also important to choose a reducer that is affordable and provides good value. This can save money and maximize efficiency and effectiveness, thereby meeting various needs.

Installing a new NRG reducer is not difficult. One can do it as long as they have the right tools and skills. Below are the tools required and the step-by-step process.

Tools Required

Step-by-Step Process

Q1. What is the function of the NGV reducer?

A1. The NGV reducer, also known as the gas reduction valve, is a critical component of CNG systems in vehicles. Its primary function is to reduce the high pressure of CNG from the cylinders to a lower, more manageable pressure before delivering it to the engine. This ensures safe and efficient operation of the vehicle.

Q2. Do all CNG vehicles have reducers?

A2. Yes, all CNG vehicles are equipped with CNG installed in the engine. The system is designed to convert the high pressure of CNG in the cylinders to a pressure suitable for the engine. This is done by passing the gas through the reducer, which lowers the pressure to the desired level.

Q3. What kind of maintenance does the NGV reducer need?

A3. Regular maintenance of the NGV reducer is essential for optimal performance. This includes periodic inspections to check for wear, leaks, and proper functioning. It is also important to clean the reducer and lubricate moving parts according to the manufacturer's recommendations. Using high-quality CNG can help minimize deposits and extend the life of the reducer.

Q4. How long does an NGV reducer last?

A4. The lifespan of an NGV reducer can vary depending on several factors, including usage, maintenance and quality. On average, an NGV reducer can last between 100,000 and 200,000 kilometers. However, with proper maintenance and care, it is possible to extend its useful life.