(161208 products available)

Recycled plastic manufacturers are changing the game by creating recycled plastic products. Usually, these manufacturers are entry-level to mid-level buyers who are looking for quality work that is not too expensive. They may do small to medium-sized orders of items they make from recycled plastic.

About 90% of the world's plastic gets made by just 20 companies, but it is worth knowing that there are different kinds of recycled plastic. They are in two major categories. The first is post-consumer plastic, which comes from things people use every day, like containers and packaging. The second is post-industrial plastic, which comes from before when products were made, like excess plastic from factories and manufacturing plants. PS, post-industrial plastic is usually a lot cheaper and easier to get.

Around 350 million tons of plastic are produced every year around the world, and only about 9% gets actually recycled. New technologies and methods are helping more and more plastic get recycled and turned into plastic products people can use every day, like eco-friendly paving slabs, benches, and roof tiles. Find out more about these types of plastic in the table below.

Production capacity:

The quantity of recycled plastic a manufacturer can process and produce per time depends on their machines' capabilities, production lines, and workforce. Some may be able to handle several tons of plastic trash monthly, transforming it into useful materials for other industries.

Product varieties:

Different types of recycled plastic, like PET, HDPE, PVC, PP, etc., require specific handling methods and technologies. Not all manufacturers can deal with every kind; some may focus on particular plastics that are more commonly found in households or businesses.

Quality standards:

Plastic waste has to be cleaned and sorted very well before it arrives at the manufacturer's facility. This can affect the quality of the final products. Depending on the initial material, some manufacturers may be able to meet top-tier international quality standards for recycled plastic, while others are more suited for local use and slightly lower requirements.

Certifications:

It's essential to know what certifications a manufacturer's processes and products have. For example, does it comply with ISO standards, or do its facilities have OECO-chip certification? These sorts of things can be very important when considering who to work with for supplying recycled plastic materials.

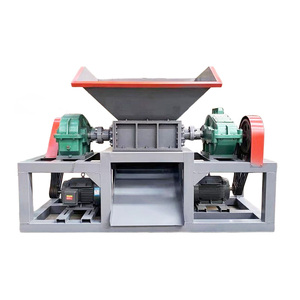

Machinery:

It's a good idea to find out about the different types of machines that a recycling manufacturer uses. This includes shredders, washers, separators, dryers, extruders, molding machines, and more. Each piece of equipment plays an important role in the recycling process, and the specific brands and models may vary from one manufacturer to another.

Service life:

Kenya plastic recycling company owners have to take good care of their machines so they can be used for a long time. Regular routine maintenance helps keep the equipment working well for many years. Things like checking motors, replacing worn parts, cleaning systems, and lubricating moving parts are all vital to extend the service life of plastic recycling machines. Proper upkeep avoids breakdowns, allowing the machines to continuously process plastic waste into valuable recycled materials over a prolonged period.

Cleaning and sterilization:

It's important for plastic recycling machines to be routinely cleaned and sanitized. Thorough washings with strong detergents and sterilizing agents help keep the systems free from dirt, grease, bacteria, and other contaminants. Regular cleaning prevents the build-up of nasty residues that could spread germs or harmful substances onto the recycled materials. Maintaining spotless, sterile equipment is vital for producing high-quality, safe plastics that meet strict health and environmental standards.

Safety features:

Recycling plastic involves many complicated machines that process material at high speeds, so it's critical that they have reliable safety features. Things like emergency stop buttons, protective covers, and guarding around moving parts help keep workers safe from any accidental injuries that could occur during the plastics recycling operation. Properly designed safeguarding is essential for allowing employees to carry out their work with peace of mind, knowing risks have been minimized, and their safety is protected.

As the global focus turns towards environmental sustainability, the applications of recycled plastic manufacturers are increasing day by day. From packaging to automotive, the list of industries that are utilizing recycled plastic is expanding at a steady pace.

Packaging Industry:

Nearly 70% of all recycled plastic is utilized in the packaging industry, which is no surprise since this sector generates the most plastic waste. Recycled PET is highly valued in the packaging industry as it is used to create water bottles, juice bottles, and other containers. RPET not only meets the rigid demands of food and beverage packaging but also allows brands to showcase their commitment to sustainability on the packaging itself.

Construction Industry:

The construction industry has become one of the biggest adopters of recycled plastic materials. From sturdy pipes to insulation boards to roofing tiles, plastics that can no longer be used for construction are finding their way into buildings instead. Plastic not only diverts waste from landfills but also adds durability and resilience to construction projects.

Automotive Industry:

Believe it or not, recycled plastic is also used in cars! Recycled polypropylene and other types of plastics are being used to make interior panels, carpets, and even bumpers. Not only does this help reduce plastic waste, but it also lightens the weight of the vehicle, which in turn improves fuel efficiency.

Wholesale recycled plastic manufacturers prove beneficial for the environment as they help reduce waste. But despite all these benefits, it is imperative to choose plastic manufacturers carefully. Here are some tips for selecting plastic manufacturers who recycle:

Q1: What type of machines are used in recycling plastic production?

A1: Several types of machines are used in the production of recycled plastic. The type of machine will vary according to the material being recycled and the end product required. A few examples of machines used in the recycling of plastic are shredders, granulators, centrifuges, extruders, and injection molding machines.

Q2: What are the benefits of using recycled plastic?

A2: There are many benefits to using recycled plastic. In the production of new plastic products, it reduces the demand for new plastic. This, in turn, reduces the energy use and greenhouse gas emissions associated with the extraction of fossil fuels, their transport, and the refining of the material. The use of recycled plastic diverts waste from landfills and encourages a recycling culture.

Q3: What kinds of plastic can be recycled?

A3: Not all plastic material can be recycled. Many plastic products have additives that make recycling uneconomical or technically unfeasible. Offsets, for example, are sometimes used to give dark-colored plastics their pigmentation, which can affect the integrity of the material when recycled. Some types of plastics have been identified as being too contaminated or damaged to be economically recycled. These include PS, PVC, and multi-layered materials. Single-layered plastics such as PET, PP, and HDPE can be recycled.

Q4: What is the process of recycling plastic?

A4: The recycling process begins with the collection of plastic material. It is then sorted according to the type of plastic. Once sorted, it is cleaned, stripped of any labels, and shredded into small pieces. Washing, drying, and granulating follow until the material is in pellet form. The plastic is then melted and formed into new products.

Q5: What is the market for recycled plastics?

A5: The global market for recycled plastics is growing. Demand for eco-friendly products is increasing. High-density polyethylene (HDPE) plastic, used for containers and bottles, is the most sought-after recycled material. The single-use bottle market is also growing due to increased consumption in the medical field and Covid-related requirements.