(3352 products available)

Rectangle grating is used in various industries. It is made of different materials and designs to meet different needs. Here are the common types of rectangle grating:

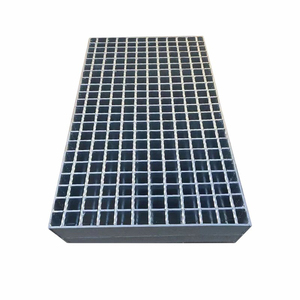

Steel Rectangle Grating

This rectangle grating is made from steel bars welded together to form a grid pattern. The steel used is usually galvanized or stainless. Galvanized steel is coated with zinc to prevent rust. This rectangle grating is durable. It can support heavy loads and is used in industrial applications like walkways, platforms, and drainage covers. The galvanized steel rectangle grating has different types, like welded steel grating, pressure-locked steel grating, and riveted steel grating.

Aluminum Rectangle Grating

This grating is made from aluminum bars that are processed and arranged in a grid pattern. It is lightweight but very strong. This makes it easy to handle and install. Aluminum rectangle grating does not rust and is resistant to corrosion. It is used in applications like walkways, bridges, and ventilation covers. The common types of aluminum rectangle grating are welded aluminum grating, pressure-locked aluminum grating, and removable bar grating.

Fiberglass Reinforced Plastic (FRP) Grating

This rectangle grating is made from plastic resins reinforced with fiberglass strands. It is lightweight and very strong. The plastic resins are mixed with pigments to make them UV stable and prevent degradation from the sun's rays. This rectangle grating is used in corrosive environments like chemical plants and wastewater treatment facilities. It is non-conductive and does not rust.

Rectangular Hole Metal Grating

This grating features rectangular openings in a grid pattern. The openings allow air, light, and water to pass through. They also provide slip resistance and support for foot traffic. The common materials for this rectangle grating include galvanized steel, aluminum, and stainless steel. It is used for industrial flooring, drainage covers, and decorative applications.

Barbecue Grill Grate

This grate has a heavy-duty construction. It can withstand the weight of large cuts of meat and the high heat of outdoor grills. The design usually features flat bars with a slight crosshatch pattern. This prevents food from slipping through the grate while allowing air circulation. The materials used to make it include stainless steel, cast iron, or chrome plating. It is easy to clean and resistant to rust.

Rectangle metal grating features an open grid pattern. The function of this product is to allow light, air, and heat to pass through. This is beneficial in many applications. Other features and functions include the following:

Strong and Durable

Rectangle grating is made from durable materials. This includes steel, aluminum, and fiberglass. These materials offer strength and durability. They are suitable for applications where durability is needed. This includes industrial and commercial environments.

Load-Bearing Capacity

Rectangle metal grating is strong and durable. It has high load-bearing capacity. This allows heavy objects to rest on it without bending or breaking. Different types of rectangle grating offer different load-bearing capabilities. For instance, steel grating has a higher load-bearing capacity than aluminum or fiberglass grating.

Slip Resistance

Slip resistance is an important safety feature of rectangle metal grating. Its surface design allows it to offer traction. This prevents slips and falls, especially in areas with high foot traffic or where water is present. Slip-resistant rectangle gratings enhance safety in workplaces and other environments.

Corrosion Resistance

Some materials used to make rectangle grating are aluminum and galvanized steel. These materials can resist rusting and corrosion. Corrosion-resistant rectangle gratings can withstand exposure to moisture, chemicals, and harsh weather. They are ideal for use in marine environments and wastewater treatment plants.

Customization

Rectangle metal grating can be customized to fit different needs and requirements. It can be made from different materials, bar sizes, and spacing. Customization allows rectangle gratings to be used in different industries. This includes construction, manufacturing, and transportation.

Easy Installation

Most types of rectangle grating are easy to install. They can be joined using welding, clips, bolts, or screws. Rectangle gratings offer safe and secure installations. They are also easy to replace and maintain.

Low Maintenance

Rectangle metal grating requires little maintenance. It is durable and corrosion-resistant. This allows it to maintain its functionality and appearance over time. Users have to regularly clean it to remove dirt and debris.

Rectangle gridings are versatile and can be used in different industries. Some common application scenarios include:

Construction and Architecture

Rectangle metal grid is used in the construction industry to build walkways, stair treads, and platforms. They provide a safe and durable solution for high-traffic areas. These gratings are also used as architectural facades, bridges, and drainage covers.

Industrial Applications

This includes oil and gas, mining and metallurgy, chemical and petrochemical, power generation, water treatment, and wastewater facilities. Rectangle gridings are used in these industries for platforms, walkways, ventilation covers, and industrial flooring.

Infrastructure

Rectangle gratings are used in infrastructure applications like bridges, highways, railways, and tramways. They are also used in airport runways, military landing fields, and helipads.

Drainage and Sewage Systems

These gratings are used as drainage covers and grates in stormwater management systems, industrial drains, and sewage systems. They allow water to pass through while preventing debris from clogging the system.

Environmental Control

Rectangle metal grid is used in air conditioning systems, HVAC, and environmental control systems. They are used in the construction industry to build ventilation covers, exhaust grates, and air intake filters.

Agriculture

These include cattle and animal farming, poultry houses, and equipment storage. Rectangle grating provides a durable and slip-resistant surface for animals, manure management, and feeding areas.

Marine and Offshore

Rectangle gratings are used in the marine and offshore industries. They are used in shipbuilding, oil rigs, offshore platforms, and marine structures. They provide a lightweight, high-strength, and anti-slip surface for harsh environments.

Railway and Transportation

These gratings are used in railway stations, subways, and transit systems. They provide a durable and low-maintenance surface for high-traffic areas, train platforms, and pedestrian walkways.

When selecting the right type of rectangle grating for a project, it is important to consider various factors. Here are some of them:

Material

The materials used for fabricating rectangle steel grating affect its performance and applications significantly. Steel offers durability and high load-bearing capabilities. It is ideal for demanding applications, and this steel rectangle bar is available in galvanized, powder coat, and mill finish. Aluminum is lightweight, corrosion-resistant, and aesthetically pleasing. It is perfect for walkways, platforms, and drainage covers. It is important to note that aluminum rectangle grating is more expensive than other materials. Fiberglass reinforced plastic (FRP) is lightweight, corrosion-resistant, and non-conductive. It is suitable for environments with high moisture and chemical exposure. This material is used for fabricating rectangle gratings for applications in chemical plants and marine environments.

Load capacity

Different applications require different load capacities. Consider the weight the grating will have to support. Manufacturers indicate the load capacity on the product specification. Look for the one that can support the intended load. Load capacity is determined by the material, thickness, and bar spacing. Thicker bars and closer spacing increase load capacity.

Environmental factors

Rectangle grating is used in different environments. So, it is important to consider environmental factors that can affect its performance. These factors include temperature, moisture and chemicals. Some materials offer better corrosion resistance than others. For instance, aluminum and FRP are great for corrosive environments. If the grating will be exposed to extreme temperatures, opt for materials with high-temperature resistance. Consider rectangle gratings that are designed for high performance in such conditions.

Maintenance

Some materials require more frequent maintenance than others. For instance, steel requires anti-rust coatings like galvanized steel grating to maintain its integrity. Aluminum, FRP and aluminum coatings require less maintenance. Consider the maintenance level a material needs before choosing the rectangle grating.

Safety features

Safety features improve the performance of the rectangle grating. Consider non-slip surface if traction is important for safety. This is important in areas exposed to water or oil. It is also important to prevent slip accidents in industrial walkways. Safety bevelled edges prevent tripping hazards. They are ideal for high-traffic areas. Light-reflective properties improve visibility and safety in low-light conditions.

Aesthetics

Consider the aesthetic qualities of the rectangle grating if it will be used in a visible area. Look for options with a pleasing design and finish. Optical patterns add visual interest. Aluminum offers a range of finishes, such as anodized and powder-coated.

Q1. What are the applications of rectangle grating?

A1. Rectangle grating is used in various applications, including walkways, platforms, industrial flooring, drainage covers, architectural features, and stair treads. It is widely applicable in factories, power plants, wastewater treatment facilities, and commercial and residential properties.

Q2. How to maintain and clean rectangle grating?

A2. The maintenance and cleaning process of rectangle grating depends on the material used to manufacture it. For example, if it is made from fiberglass, users can use soap and water to clean it. However, if it is made from steel, they can use a wire brush and rust-inhibiting paint to clean and maintain it.

Q3. How to prevent slip on rectangle grating?

A3. To prevent slipping on rectangle grating, manufacturers can add anti-slip coatings or textures. They can also manufacture grating with high-slip-resistant bars or inserts slip-resistant materials in areas with high water and oil.

Q4. What are the advantages of rectangle grating over solid plates?

A4. Rectangle gratings are advantageous because they provide better drainage than solid plates. They are lighter and allow natural light to pass through. Additionally, they offer superior ventilation and are more slip-resistant.

Q5. What factors affect the load-bearing capacity of rectangle grating?

A5. The factors that affect the load-bearing capacity of rectangle grating include the bar depth, the thickness of the bars, the spacing between the bars, and the material used to manufacture it. Other factors include the type of load it experiences, such as dynamic or static loads.