(82 products available)

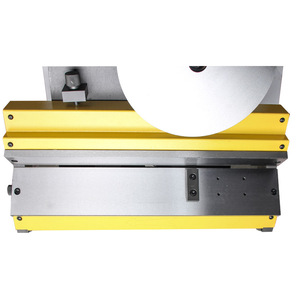

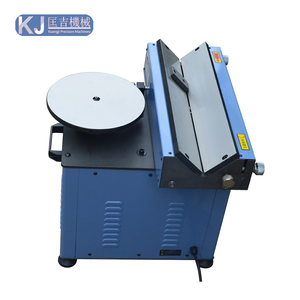

A rail deburring machine is a specialized piece of railway machinery used to remove any burrs or rough edges after the rail has been cut to the desired length. These burrs can make it difficult to couple trains to the end of the rail and may also cause issues with the comfort of train riders. A deburring machine makes smoothing these edges easy.

Deburring machines are usually powered manually, however, there are a number of different types of machines that can be used to debur railway tracks, some of which are discussed below:

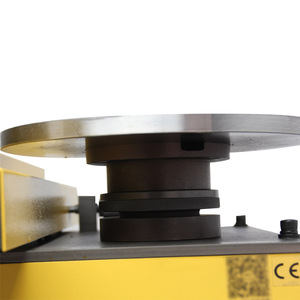

Deburring is done based on specifications. They mainly depend on the material, shape, and size of the workpiece. The machine being used for deburring also varies depending on the workpiece shape and size. Different blades and burrs work well with different materials.

Some common specs include :

Regular maintenance of the deburring machine is required for its longevity and efficient operation. It ensures the machine is constantly in a usable state.

Some important steps to maintain a deburring machine include:

Rail deburring machines work in different sectors and applications. They are crucial in the rail transport industry. Railway components typically have burrs that can affect the lifespan and performance of components, including those relating to the rails. These components will include fishplates, crossings, sleepers, switches, and the rails themselves. Removing rail burrs improves the overall component integrity and performance and enhances component fit.

Railway switching systems, known as points, also call for rail deburring machines. The junctions through which trains traverse to switch lines need components like fishplates and crossings to have a precise, smooth fit to avoid accidents. Deburring machines can quickly and accurately smoothen out edges that cannot achieve precise fits through conventional machining processes.

Heavy rolling stock, such as freight and passenger trains, use rail-deburr machines in the locomotive manufacturing industry. Fatigue failure often results from burrs found on axles, wheels, and chassis. They can seriously threaten the health and safety of persons and property on and near the railway lines. Therefore, deburring machines are essential to enhance the safety and longevity of locomotives and their rolling stock.

In the metals processing industry, rail deburring machines can smoothen out edges of metal strips, rods, plates, and other geometries that need machining. They are sometimes referred to as 'metal deburring machines,' but the specific machine type required will depend on the metal shape and the extent of the burrs that need removing. Metal deburring machines can use various methods and cutting tools to carry out deburring. This includes non-metal edges that need machining, such as plastics. Some deburring machines also have cylindrical brushes.

Manufacturers of metal products can benefit from employing a rail deburring machine because they increase productivity by eliminating manual deburring, which tends to be slow and laborious. Consistency and product quality improve when using a deburring machine, and the health and safety of workers can be prioritized, meaning fewer accidents from manually handling sharp edges.

Other manufacturing industries that come into contact with metals, including those using rails and other heavy metal products, use rail deburring machines, including:

Depending on the type of rail deburring machine, these devices can also be used for the following:

While purchasing deburring machines for rails, certain essential factors must be considered to select the most suitable options for specific needs. The first and most important thing is to identify the kind of material the machines will be working on. Different materials, such as steel, cast iron, or other alloys, may have distinct characteristics that could influence the choice of the rail deburring machine.

Consider the size, weight, and thickness of the rails that need deburring. The dimensions and weight of the rail will impact the selection of the machine's size and capacity, ensuring that it can accommodate the rails with ease and stability. Also, the burr types can vary widely, and the chosen machine must be capable of handling the specific kinds of burrs that are present on the rails to achieve the desired level of smoothness and functionality.

The production volume refers to the number of rails that need deburring within a specific timeframe. As discussed earlier, the required level of automation can also influence the production volume. Consider the available space where the rail deburring machine will be located. The dimensions of the machine must be suitable for the installation area, ensuring that it can be positioned without causing disruptions to existing workflows.

The power supply requirements of the rail deburring machine should match the available electricity infrastructure. This ensures a safe and efficient operation without the need for additional power supply modifications or installations.

Budget constraints are another important things to consider. Businesses must select machines that provide the best value for investment while considering maintenance costs, energy efficiency, and potential productivity gains.

Finally, the project deadline is an important business aspect of the decision-making process, as the timely delivery of rail deburring machines is crucial for project success and avoiding costly delays. Taking these factors into account helps make an informed choice that aligns with operational needs, budget constraints, and future growth possibilities.

Q1: Can a rail deburring machine handle different types of metals?

A1: Yes, many rail deburring machines are designed to handle different types of metals, including carbon steel, stainless steel, and alloy steel. However, this may depend on the specifications of the machine. It is important to check the machine's specifications to ensure it can handle the type of metal in use.

Q2: Can a rail deburring machine be automated?

A2: Yes, it is possible to automate some deburring machines. Automation can improve efficiency and reduce the need for manual intervention. However, the requirement for automation will depend on the machine type and the processing needs.

Q3: What safety features should a rail deburring machine have?

A3: A rail deburring machine should have several safety features. These include emergency stop buttons, safety enclosures or guards, and soft-start functions. The machine may also have cooling systems to prevent overheating. Other safety features include overload protection and anti-static devices.

Q4: How noisy is the rail deburring machine?

A4: This may depend on the machine's model and make. However, deburring machines are typically noisy. It may be necessary to use hearing protection and take other noise control measures.