(1410 products available)

PTO reducers come in many types. Each type differs in application. Here's a look at the most common PTO gear reducer types.

These PTO gearboxes use hydraulic systems to transmit power. Thus, they provide a smooth and controlled power transfer. The key features include:

These PTO gear sets are electric-powered. They are usually applied where hydraulic systems are absent. This reducer type is ideal for:

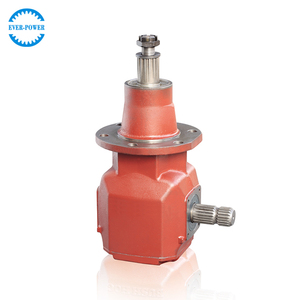

These reducers use gears to provide power transfer. These remain among the most common types of PTO reducers. The features that set them apart include:

Cylinder PTOs are distinguishable by their unique gear arrangement. This configuration enhances torque transmission. The features include:

The design of these PTOs helps them distribute loads evenly. Thus helps them perform particularly well under heavy-duty conditions. Here are their key features:

The choice of materials for PTO reducers influences their durability, efficiency, and ability to handle specific workloads. Below is a list of the most common materials used for making these reducers.

Cast iron remains the most popular material for manufacturing PTO reducers. This is due to its excellent wear resistance and ability to absorb shock. Some of its key properties include:

Alloyed steel is the go-to material for gears and other critical components of PTO reducers. Manufacturers love it for its exceptional strength and toughness. Below are its standout features:

Bronze is a popular choice for components such as bearings and bushings in PTO reducers. Its application is mainly where corrosion resistance and low friction are required. Its key benefits include:

Manufacturers make these plastics for some PTO components. These plastics are economical and have good wear resistance. They are also lightweight. Below are more of their pros:

Chrome is a popular choice for coating teeth in PTO gearboxes. It is ideal for improving wear resistance and extending the life of the gears. Also, chromium has many benefits. They include:

People use PTOs in many harsh commercial applications. Here are their most popular uses:

Agricultural equipment uses PTO reducers to power various implements. The reducers help handle the high torque required by the tools. They also regulate the speed to ensure optimal performance. Here are some tools that rely on these reducers:

PTO reducers in trucks power hydraulic pumps and other tools. Therefore, they provide the necessary power for various tasks. Commonly, these reducers help the trucks perform as they usually do when powered by engines.

Besides, the PTO reducers offer better fuel efficiency. Thus, they reduce the overall operational costs for construction companies. Some equipment that relies on these reducers includes:

Forestry equipment heavily relies on PTO reducers to operate efficiently. Usually, they use the reducers to help manage the high power requirements of various tools. Thus, they are crucial for sustainable forest management. The PTOs protect the trucks by powering forestry equipment using the trucks' main engines.

PTO reducers in vehicles power various auxiliary systems. These systems include hydraulic lifts, winches, and air compressors. Hence, they are vital in many transportation operations. Below are some applications that rely on these reducers:

Choosing the right PTO reducer for clients requires considering several factors. Below are these factors.

Always check the customer's load requirements before placing an order. Generally, load capacity refers to the maximum weight a reducer can handle. It's an important factor as it affects the reducer's durability and performance. So, choosing the right load capacity will help prevent overloads. These overloads can damage gear parts or even motors.

A PTO's operating speed determines how fast it can transfer power. Manufacturers usually rate this speed in revolutions per minute (RPM). Always consider the customer's speed requirements. This will ensure the optimal performance of attachment systems and machines. Operating beyond the required speed can cause overheating and excessive wear or even system failure.

The gear ratio of PTO reducers is vital for buyers looking to keep their equipment working flawlessly. So, what's a gear ratio? It is the relationship between the input and output speeds of a reducer. It influences the overall power transmission. A high ratio offers more torque, while a low ratio ensures higher speeds.

Buyers should consider the type of power source when purchasing these PTOs. Normally, manufacturers make PTOs to work with various power sources. They include hydraulic systems, electric motors, and internal combustion engines. Buyers looking for PTOs to help smoothly reduce their customers' operational costs should consider electric-powered PTOs. Normally, they are more energy-efficient than hydraulic ones.

Material quality is a crucial consideration. It will directly affect the PTO's durability and reliability. Plus, it also impacts maintenance requirements. So, which materials make good PTOs? They include high-strength steel alloys, chrome, and cast iron. This is because they offer high wear resistance while ensuring optimal performance. Also, they are the go-to choice for buyers looking for PTOs that can work in harsh conditions.

Yes, people can use electric Motors with hydraulic PTOs. The hydraulic pumps help the PTOs distribute the hydraulic fluid generated by the electric motor throughout the hydraulic circuit. This functionality makes it an excellent alternative power source, especially in areas where using other power sources would be unfeasible.

No, the PTOs have different designs, operational characteristics, gear ratios, and power sources. These differences make them suitable for specific applications. So, using a PTO in an application it was not designed for can lead to poor performance. It can also cause damage to the PTO itself. Always refer to the manufacturer guidelines for the specific application. They will provide the necessary information on which PTOs are most compatible with particular applications.

Yes, many manufacturers are focusing on improving the energy efficiency of these reducers. They do this by integrating advanced materials and designs. These materials reduce friction and power losses. Also, PTOS designed to work with electric motors are gaining popularity due to their increased energy efficiency. Hence, they are a more sustainable option for various industrial applications.

It's important to regularly check the lubrication levels for these reducers. Manufacturers recommend users service the reducer as indicated by the manufacturer. Usually, proper maintenance ensures the reducer operates smoothly. It also extends its lifespan. Specific maintenance requirements like lubrication intervals, inspection schedules, and component replacements vary from one manufacturer to another. So, always refer to the manufacturer's manual for maintenance tips.

The gear ratio is one of the most important operational parameters of a PTO. It affects power transmission, speed, and torque. Moreover, a higher gear ratio means increased torque. This makes them suitable for heavy-duty tasks. Conversely, a lower gear ratio ensures higher speeds, ideal for light-duty applications. Exposing the reducer to tasks that exceed its operable limit can cause system failure.