(23535 products available)

A precise grinder is designed to give a consistent grind for brewing equipment. It comes in various types, each providing a different level of precision when it comes to grinding.

Blade Grinders

They are the most basic form of grinders. They consist of a single rotating blade that chops coffee beans as it spins. While they are affordable, their consistency is less common. This is because the blade's speed and chopping vary. Sometimes, they end up producing uneven grinds, which is not ideal for brewing coffee.

Cylinder Grinders

These grinders contain two cone-shaped stones that rotate against each other. As they rotate, they crush the coffee beans into powder. The grinders are generally more consistent compared to blade grinders. This is because the stones' shape and size provide a more even crushing of the coffee beans. However, the grinders can be a bit less precise when it comes to grind size.

Flat Burr Grinders

These grinders have two flat burrs that sit parallel to each other. The burrs can be adjusted to provide a consistent and precise grind size. The grinders produce a uniform grind size, which is consistent for different brewing methods.

Conical Burr Grinders

The grinders have a cone-shaped burr that sits inside another cone. They produce a consistent grind and are preferred for brewing equipment. The grinders are less noisy compared to flat burr grinders.

When purchasing a precise grinder, it is important to consider the budget. Also, think about the preferred grind size and consistency, the level of noise, and the convenience of use. Extra features such as programmable settings and advanced technology may influence the price of the grinder. Such grinders may offer more control over the grind size and consistency. Also, they usually provide more value and better performance.

Material:

The grinder is made of stainless steel, which is durable and resistant to corrosion and oxidation. The precise grinder is also made of food-grade plastic, which is BPA-free. An acrylic spice grinder is also available.

Blade:

To prevent spice contamination, the precise electric grinder has stainless steel blades that are rust-resistant and durable. They also retain sharpness after many uses.

Motor Power and Grinding Chamber Capacity:

The motor power of a precise grinder can start from 150W, with some models going up to 300W. Models with higher motor power can handle more spice grinding loads. The Grinder's Grinding Chamber Capacity can range from 40g to 125g or more, depending on how much the user wants to grind once.

Grinding Settings:

Some precise grinders have adjustable settings, so the user can choose the preferred coarseness or fineness. These settings can include a 12-cup set, a 10-cup set, an 8-cup set, a French Press set, and more.

Easy to Clean:

Grinders that come with a brush make it easier to clean the grinding chamber after every use. There are also models with removable grinding jars.

Multipurpose:

Different types of grinders are available. Some models are designed to grind spices, while others are meant to coffee beans, nuts, or herbs. There are also grinders that are suitable for general use.

Safety Features:

Precise grinders come with safety features such as a rubber grommet that prevents the grinder from functioning if it is incorrectly assembled. Some models have a safety switch that prevents the motor from operating without being properly locked.

As seen in the earlier sections, precise grinders play an important role in various industries. Here are some usage scenarios of precise grinders:

Manufacturing industry

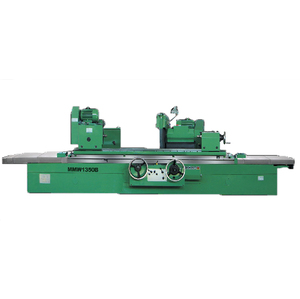

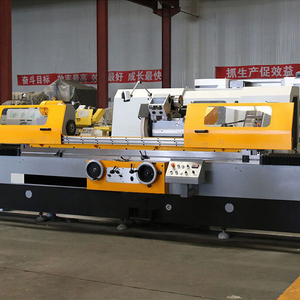

The manufacturing industry uses precise grinders during the fabrication process of various components. Precise grinders help to achieve the required dimensional accuracy and ensure that all parts fit together perfectly. These grinders are also used widely in the production of tools and molds. Precise grinders play a key role in creating tools, molds, and dies that have complex shapes and tight tolerances. These are essential for the manufacturing of various components in the automotive aerospace and industrial sectors. Also, in the manufacturing industry, precise grinders help in producing tools and cutters used in machining operations. These grinders ensure that cutting edges are sharp, which improves the performance of the tools and reduces the need for frequent replacements.

Metalworking industry

In the metalworking industry, precise grinders are used to sharpen and extend the lifespan of cutting tools. This provides an ideal solution for maintaining the effectiveness of various tools. The grinders are also used to remove material from metal parts during the fabrication process. Their high precision ensures that all tolerances are met, and that the final products comply with industry standards. Additionally, the metalworking industry uses precise grinders to modify the shape of metal components. This is important to achieve the desired configuration in obtaining parts that meet specific requirements.

Tool and Die Industry

In this industry, precise grinders are used to manufacture tools, dies, and other machining components with high accuracy. Also, the grinders are used to repair and refurbish these types of components. Their high precision enables the restoration of the required tolerances and geometric specifications. This prolongs the service life and performance of the tools and dies. Moreover, precise grinders are used in the tool and die industry to create intricate patterns and textures on various surfaces. This adds decorative features and improves the functionality of different types of stamped or machined parts.

Aerospace industry

In the aerospace industry, precise grinders play an important role in the production of aircraft engines and other high-precision components. They are also used to manufacture parts with complex shapes such as contoured surfaces and intricate geometries. This enables the assembly of critical components with tight tolerances. The aerospace industry also uses precise grinders for the production of instruments and parts. Their high precision ensures that all functional requirements are met, which guarantees the performance and reliability of various systems. Additionally, precise grinders are essential in the aerospace maintenance and repair sector. They are used to restore worn-out parts and bring them back to the required specifications.

Jewelry making

Precise grinders are used in the jewelry making process to grind and shape metal with high precision. This enables the creation of intricate designs and ensures that the final pieces meet the required specifications. Also, these grinders are used to polish gemstones during jewelry making. The grinders provide a smooth and polished surface that enhances the beauty and value of the gemstones. Furthermore, precise grinders are used in jewelry making to remove any excess metal or make adjustments to the ring size. This ensures that each piece fits perfectly and has the desired dimensions.

Sharpening Services

Precision grinders are employed in professional sharpening establishments that cater to knives, scissors, and other cutting tools. This restores their original sharpness and edges. As a result, precision grinding enhances the performance of the tools and reduces the need for frequent replacements. This ensures that cutting edges are consistent, which results in clean and accurate cuts.

Research and Development

Precise grinders are useful in the development of new products. These grinders aid in the production of prototypes with high accuracy. This allows for proper testing and validation of new designs. Additionally, precise grinders are used in the research and development process for material experimentation. Researchers can试用不同的材料,使用准确的研磨机进行精确的处理,以确定物质的特性并获得所需的性能。进一步的研磨机还可以用于优化工作中的各种条件,例如温度、压力和速度。这可以改善材料的质量,从而提高最终产品的质量。此外,研究和开发中的准确研磨机对于精确测量和控制尺寸和公差至关重要。因此,具体设计可以根据规范进行评估并进行修改,以确保符合要求。

When buying precise coffee grinders for wholesale purchase, buyers should consider quantity and quality. They should buy grinders that can serve different levels of customers in the market.

Therefore, buyers should purchase precise grinders that are inexpensive, mid-range, and high-end to attract different customers. Also, they should buy precise grinders with different functions and features.

Grinders with basic functions such as manual adjustments and on and off buttons tend to attract budget customers. On the other hand, grinders with many functions like automatic adjustment, A, B, and C grind level selection will attract high-end customers.

These types of customers are usually ready to spend more money on additional features that offer more convenience. Buyers should also purchase precise grinders made from different materials. For instance, grinders made from stainless steel and plastic are more affordable than those made from aluminum and titanium. Normally, plastic and stainless steel grinders have less durability compared to aluminum and titanium grinders. Also, when buying precise coffee grinders for wholesale purchase, buyers should consider the grinder's capacity. Moreover, they should consider the expected customer base.

A precise grinder with a small capacity is ideal for households, while medium to large capacity grinders are suitable for commercial use. Large capacity grinders can also serve a large household. Buyers should also consider the build quality of the grinder. Stunning grinders invariably attract customers' attention. Grinders with appealing appearance also have more chances of being bought in the retail market.

Buyers should also consider the brand when purchasing wholesale precise grinders. Reputable brands are more likely to produce high-quality precics gringers. They also offer after-sale services, which reduces the burden of the buyers in case the grinder develops issues.

Grinder brands also impact the price range of the precise grinder, thus influencing the buyer's decision. Buyers in need of large quantities should consider ordering the grinders from a specific manufacturer. Ordering a specific number of grinders can earn the buyer a discount. Wholesalers and retailers can also benefit from ordering specific custom-made precise grinders that are not manufactured in large numbers. Buyers can request specific additions to the grinder that can make it more efficient or any other requirements that can optimize it. In addition to this, buyers should be on the lookout for promotions and discounts on precise grinders.

Q1: What materials can be ground with a precise grinder?

A1: A precise grinder can be used on a variety of materials depending on the type. Metal, wood, plastic, and rubber can be ground using a diamond or metal-based grinder. For coffee or spice grinders, they will only grind dry foodstuff or spices. Always check the user manual to see what materials can be ground using the precise grinder.

Q2: How important is it to maintain a precise grinder?

A2: Grinder maintenance is very important for long-term performance. This is because unmaintained grinders can suffer from decreased accuracy and increased friction and wear, which can affect the quality of the ground product. Regular maintenance helps to identify and fix any potential problems early.

Q3: What businesses benefit from using precise grinders?

A3: Different industries use precise grinders in their day-to-day activities. Metal fabrication shops, tool and die manufacturers, machine shops, automotive and aerospace industries use grinders to manufacture and repair parts. They also use precise grinders for finishing tasks that require the smooth or redured dimensions to exact specifications.

Q4: How can operators ensure safety when using grinders?

A4: Operators should take precautions to ensure safe grinder operations. These precautions include wearing protective equipment like gloves, masks, safety glasses to protect against dust and debris. Also, do not wear loose clothes or jewelry when operating the grinder. Ensure there is proper ventilation because some materials will produce harmful fumes when ground.